Sustainable recycling of containers and packaging

Sustainable recycling of containers and packaging

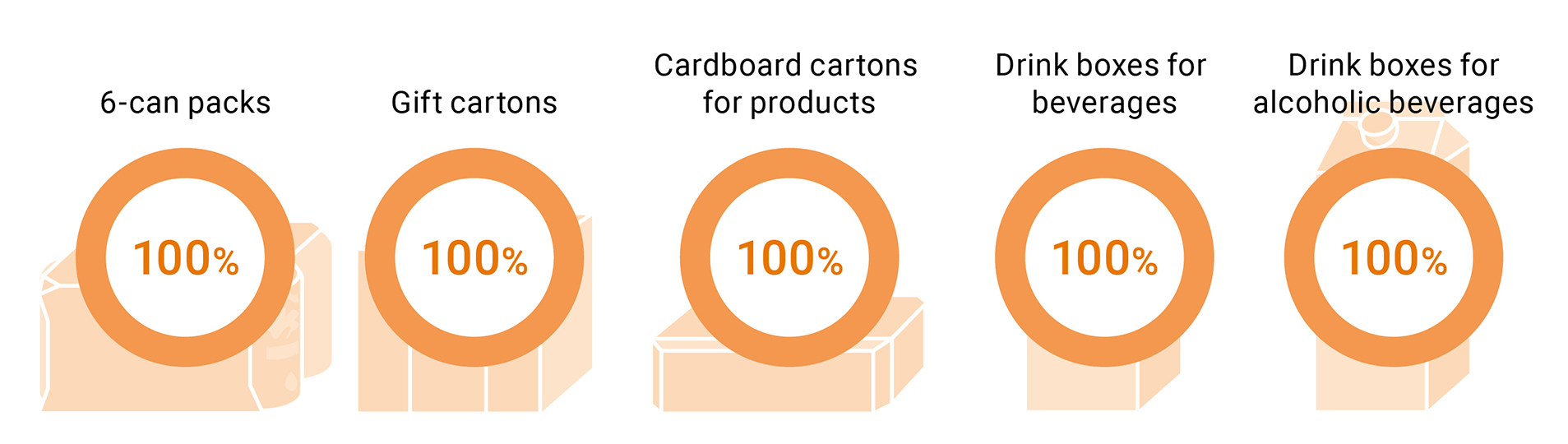

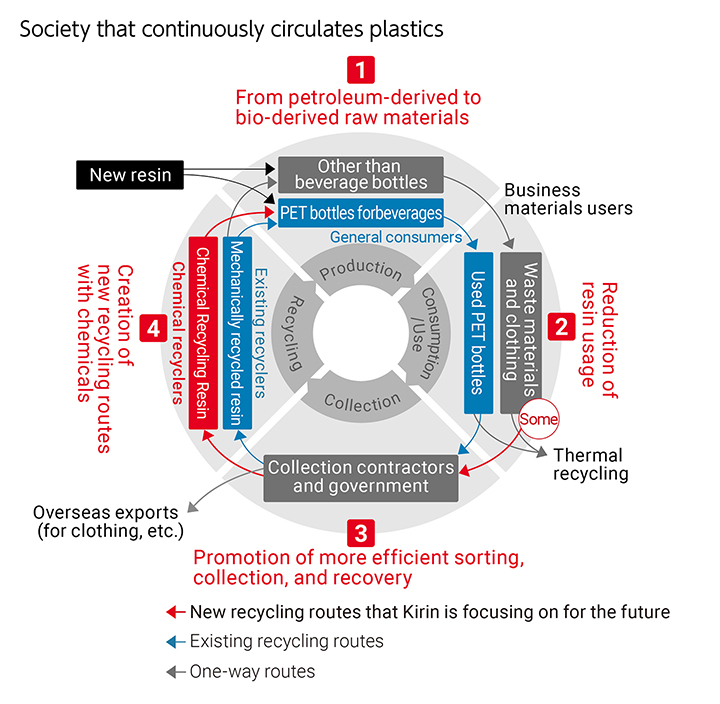

Containers and packaging are essential to maintain the quality of products when delivering them to customers. To address the various issues caused by containers and packaging, the entire industry has promoted 3R (reduce, reuse, recycle) and achieved a high recycling rate. With regard to paper containers, in order to solve problems related to human rights and the destruction of forests that provide raw materials, we soon began promoting sustainable paper use. By the end of 2020, we had achieved 100% use of FSC-certified paper and recycled paper for all paper containers in Kirin Brewery, Kirin Beverage, Mercian, which we have subsequently maintained. Furthermore, we plan to expand this initiative to all Kirin Group companies, including those overseas. In response to issues related to plastics, we aim to solve issues specific to countries where we operate our businesses and create a “society that continuously circulates plastics” from the global perspective.

Main Activities

- Since November 2023, we have joined the Business coalition for a global plastics treaty (Japan), which works to make policy recommendations to the Japanese government in order to formulate an international treaty to end plastic pollution.

- Expanded use of "R100 PET bottles" made from 100% recycled PET resin

- In order to reduce plastic usage, we began selling no label products (2021: Kirin Gogo-no-Kocha Oishii Muto(Sugar free) and Kirin FIRE ONE DAY BLACK), shortened labels and packaging materials (2022: Kirin Nama-cha and Kirin Nama-cha Hoji Sencha), and used small paper stickers for no label products (2022:Kirin Nama-cha)

- With the aim of creating a "society that continuously circulates PET bottles," we have begun technical studies on PET recycling using "chemical recycling"

- Strengthened collaboration with other companies and local governments as part of efforts to collect PET bottles

- Maintained our achievement of the 100% use of FSC-certified paper for all paper containers in Kirin Brewery, Kirin Beverage, Mercian (2020), and adopted FSC-certified paper for paper packaging materials for no label six-bottle packs

- Set targets to use 100% sustainable paper resources at Lion (Australia and New Zealand) (by 2025)

Targets

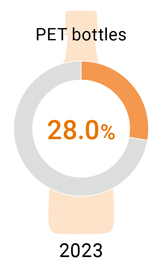

Procentage of recycled resin in Japan

2050: 100% (Environmental Vision 2050)

2027: 50% (Plastic Policy)

2024: 38% (non-financial target)

Progress

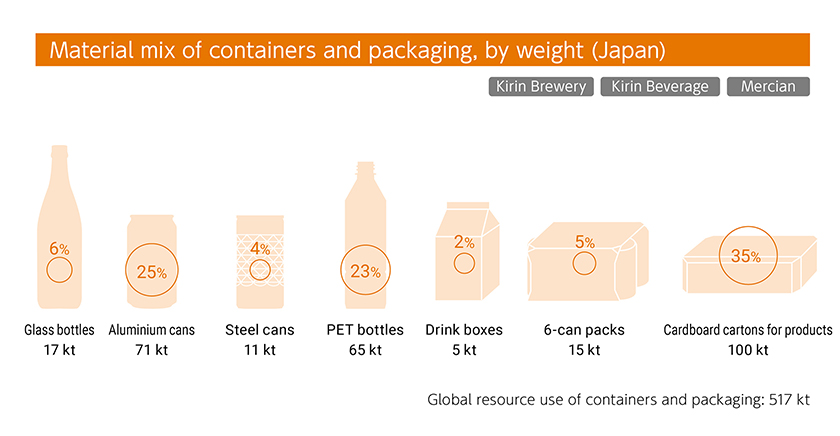

Material mix of containers and packaging by weight

Sustainable PET bottles

R100 PET bottles

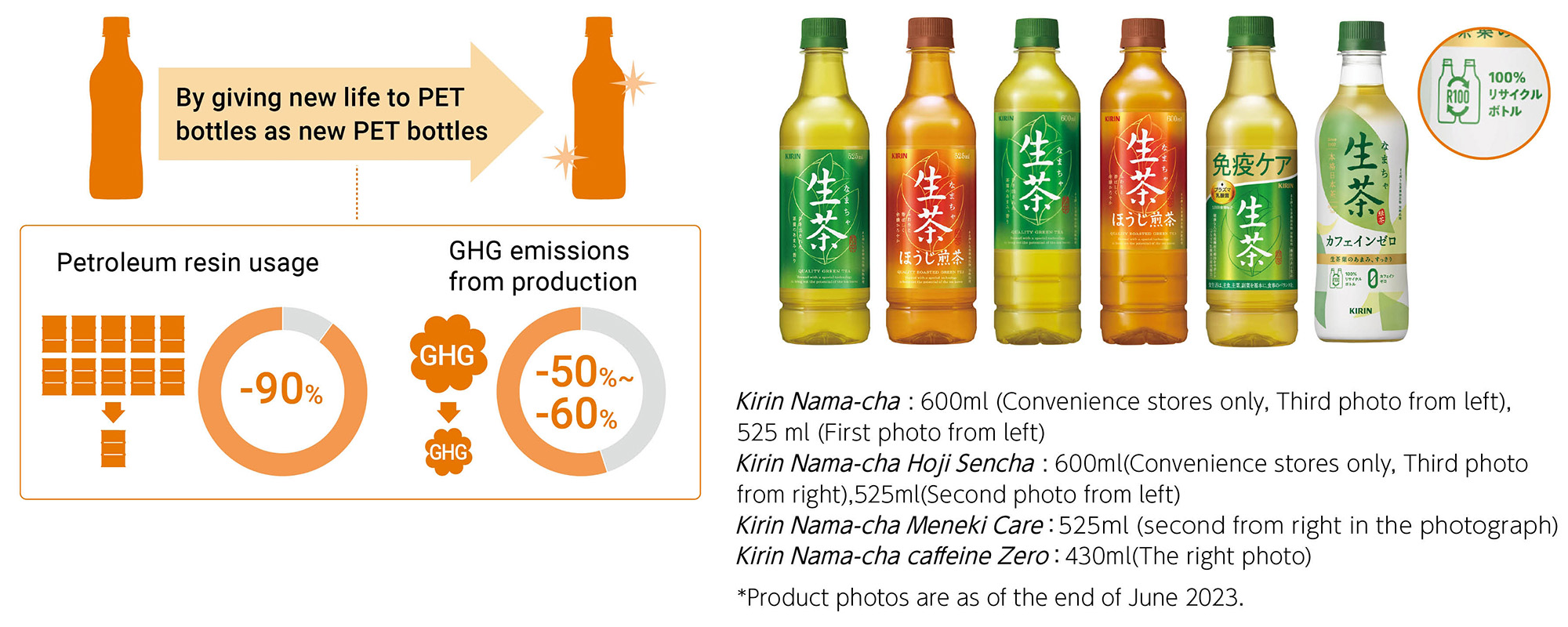

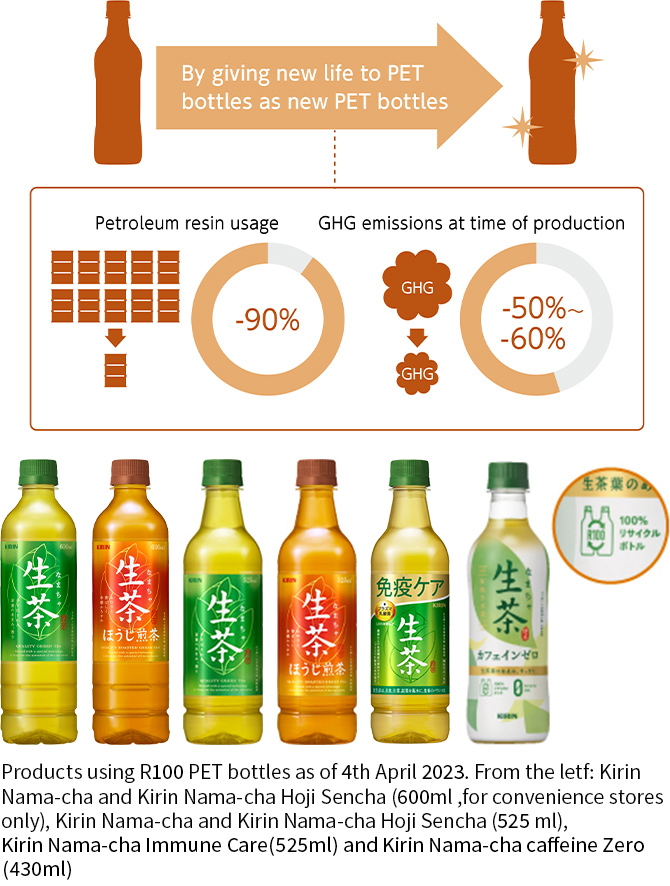

In accordance with the Plastic Policy that we established in 2019, the Kirin Group is gradually expanding the use of “R100 PET bottles” made from 100% recycled PET resin. “R100 PET bottles” use “mechanical recycling” technology to enable the use of recycled PET materials as a raw material for PET bottles. Recycled PET resin uses 90% less resin derived from petroleum and achieves a reduction in GHG emissions of 50-60% compared with regular petroleum-derived PET materials.

We began using recycled resin for some of the packaging of Kirin Gogo-no-Kocha Oishii Muto (sugar-free) product in February 2014. Subsequently, in 2019, we began using “R100 PET bottles,” which use 100% recycled PET resin, for Kirin Nama-cha Decaf.

Our use of “R100 PET bottles” as of April 2023 is as shown on the bottom.

- “Kirin Nama-cha 525ml” and “Kirin Nama-cha Hoji Sencha 525ml” have partially started to be used, and are being gradually introduced.

- Product photos are as of the end of June 2023

Chemical recycling

In December 2020, Kirin began technical studies aimed at commercialization focusing on recycling PET bottles using chemical recycling.

In the current mechanical recycling system, there are impurities that are difficult to remove from recycled resins, and it is said that the quality of resins deteriorates with repeated recycling. In chemical recycling, we sort, pulverize and wash used PET bottles to remove dirt and contaminants, then we depolymerize them (chemical decomposition treatment), and break down and purify the PET into intermediate raw materials, which we then polymerize (synthesize) again into PET. It is possible to recycle PET bottles to a state similar to new materials as many times as we want through decomposition down to the molecular level, and we can also recycle PET products other than used PET bottles into PET bottles. In December 2023, we developed an "alkaline decomposition method" that enables the decomposition of PET in a short time and with low energy consumption. Besides, we have introduced chemical recycling resin in the 3litters PET bottle used for restaurants from 2023. This is the first time in Japan that chemical recycling resin has been introduced in PET bottles for alcoholic beverages. In addition to aiming to establish a circular economy for PET products, we will build a system for collecting PET products other than PET bottles. Since 2022, we have been working with FANCL to promote the reuse of PET materials.

Promotion of more efficient sorting, collection, and recovery

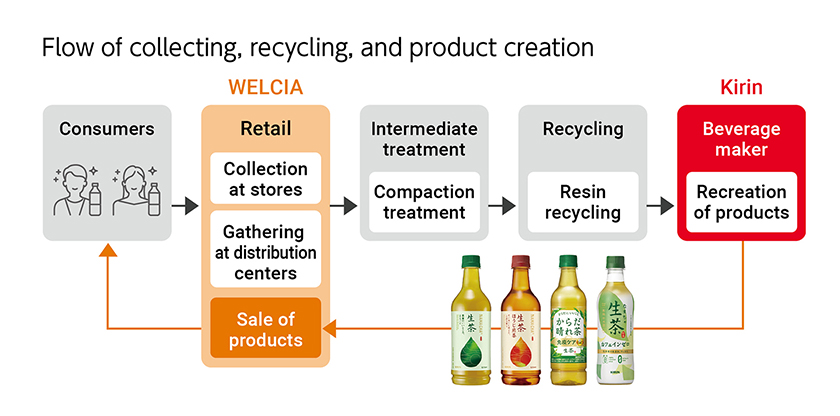

Aiming to create “a society that continuously recycles plastics,” in July 2021, we launched a demonstration trial to collect used PET bottle containers, in collaboration with Lawson, Inc. In June 2022, we expanded the demonstration to WELCIA YAKKYOKU CO.,LTD. In the demonstration trial at WELCIA, we collect and sort used PET bottles in collection boxes installed at WELCIA stores, and after gathering these materials at a WELCIA distribution center, we transport them to Far Eastern Ishizuka Green PET Corporation, a recycler.

Sustainable paper containers

At the end of November 2020, the Kirin Group achieved the 100% use of FSC-certified paper in all paper containers and packaging at Kirin Brewery, Kirin Beverage, and Mercian. The targeted paper containers are “6-can packs,” “gift boxes,” “drink boxes,” and “cardboard cartons.” This is the first declaration and achievement of that declaration by a Japanese manufacturer to cover all paper containers.

In 2022, we revised the “Action Plan for the Sustainable Use of Biological Resources,” and expanded the scope of the Kirin Group companies to include Kyowa Kirin, Kyowa Hakko Bio, Lion, and Koiwai Dairy Products. We declared our intention to switch to sustainable paper, such as FSC-certified paper and wastepaper, by 2030, and began related initiatives at those companies.

- Product photographs are current as of June 2023 or the time that events occurred.

Reduce

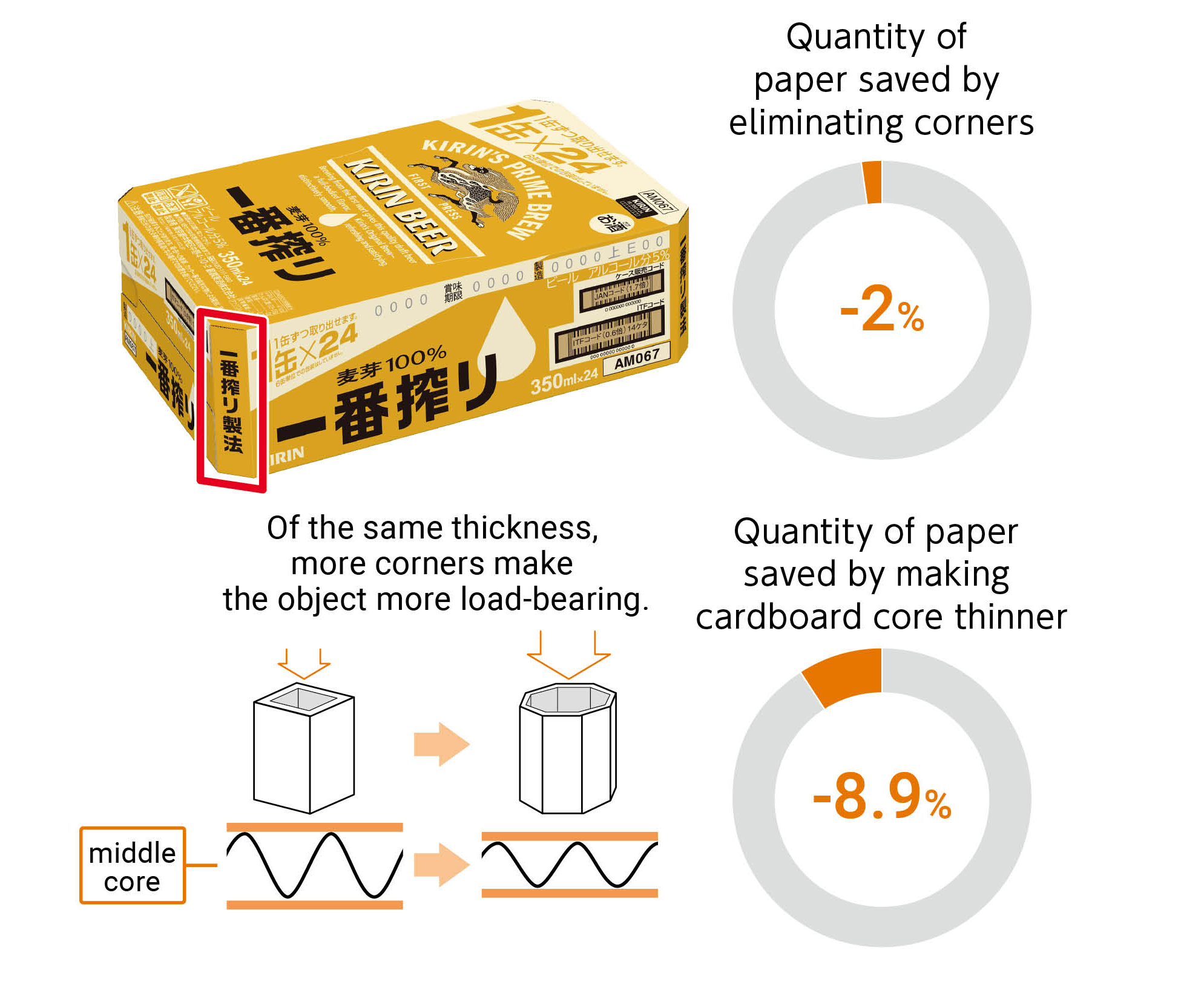

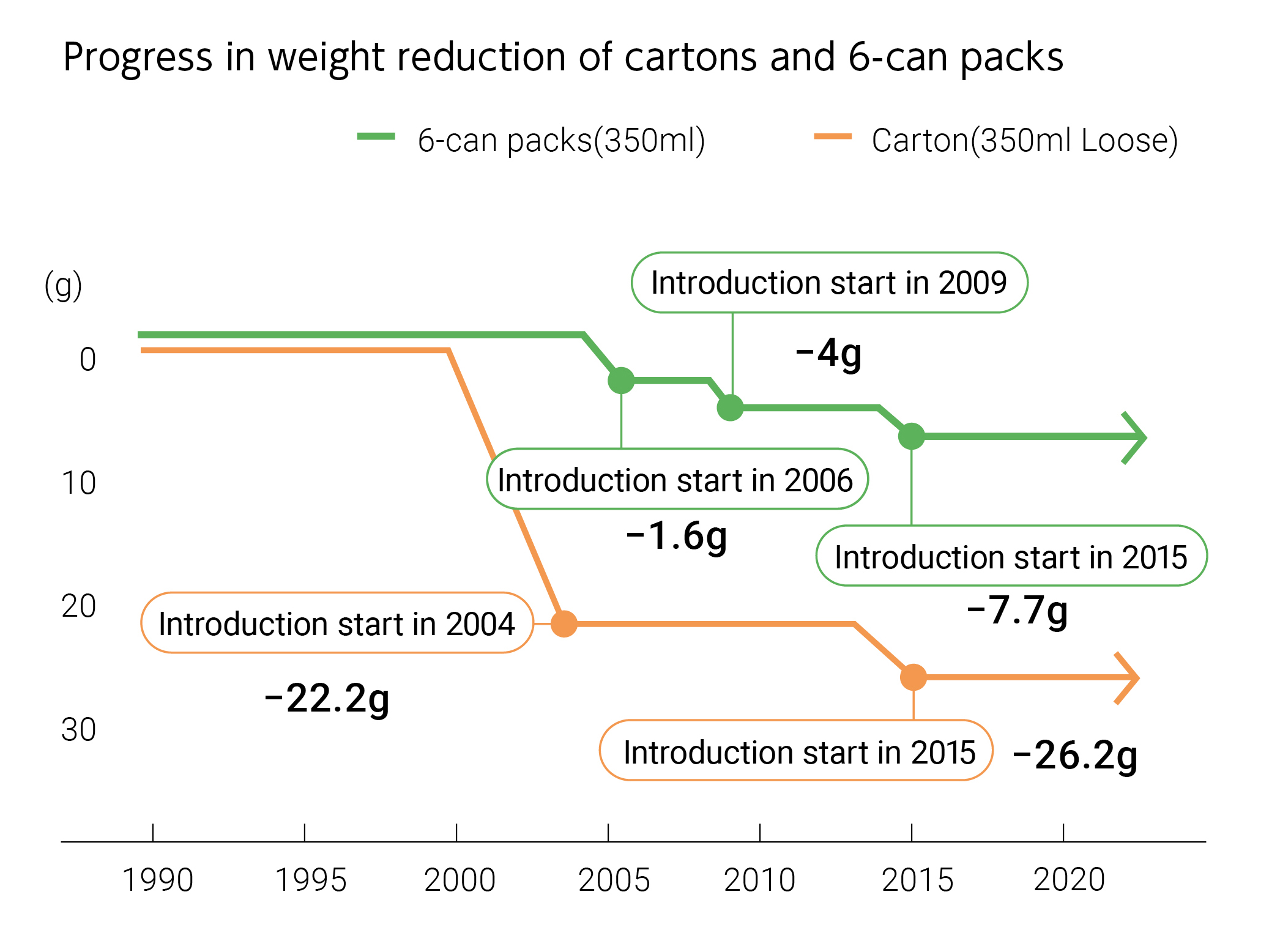

Corner-cut cartons

The Institute for Packaging Innovation developed “corner-cut cartons,” and we introduced them to the market in 2004. The beveled corners have reduced the weight of the carton and, because the carton has eight sides, making it stronger, the cardboard thickness has been reduced, resulting in a 10.9% reduction in the weight of the carton compared to conventional cartons.

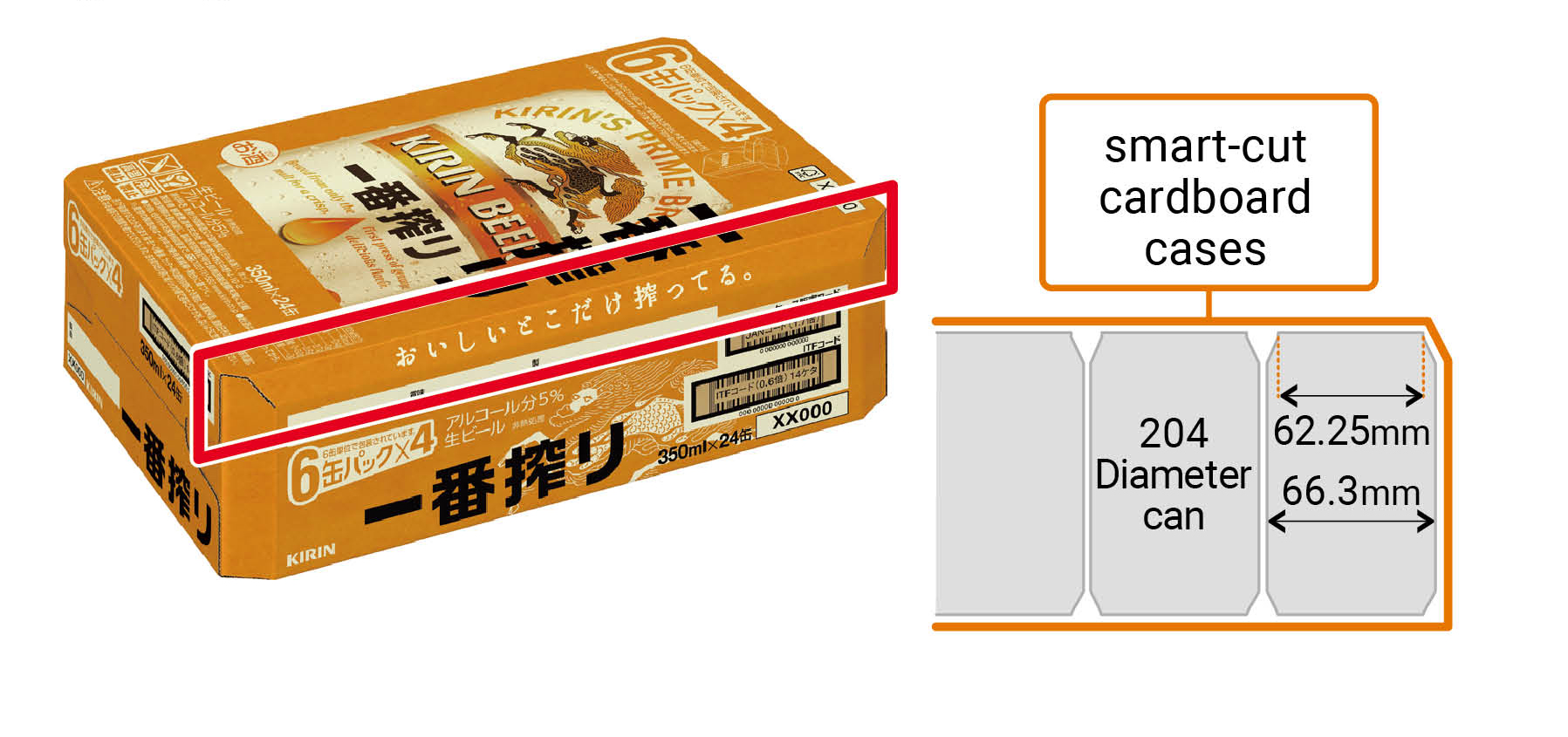

Smart-cut cartons

The smart-cut carton, which we introduced in 2015, is based on the corner-cut carton technology. In addition to the reduction in weight, the corners of the long edges at the top of the carton have been cut to fit the space created by the lids of the 204-diameter can, which are smaller than the previous can. This has resulted in a 16% weight reduction compared to the corner-cut carton. The Institute for Packaging Innovation developed the smart-cut carton in conjunction with a container and packaging manufacturer, and obtained a joint design registration.

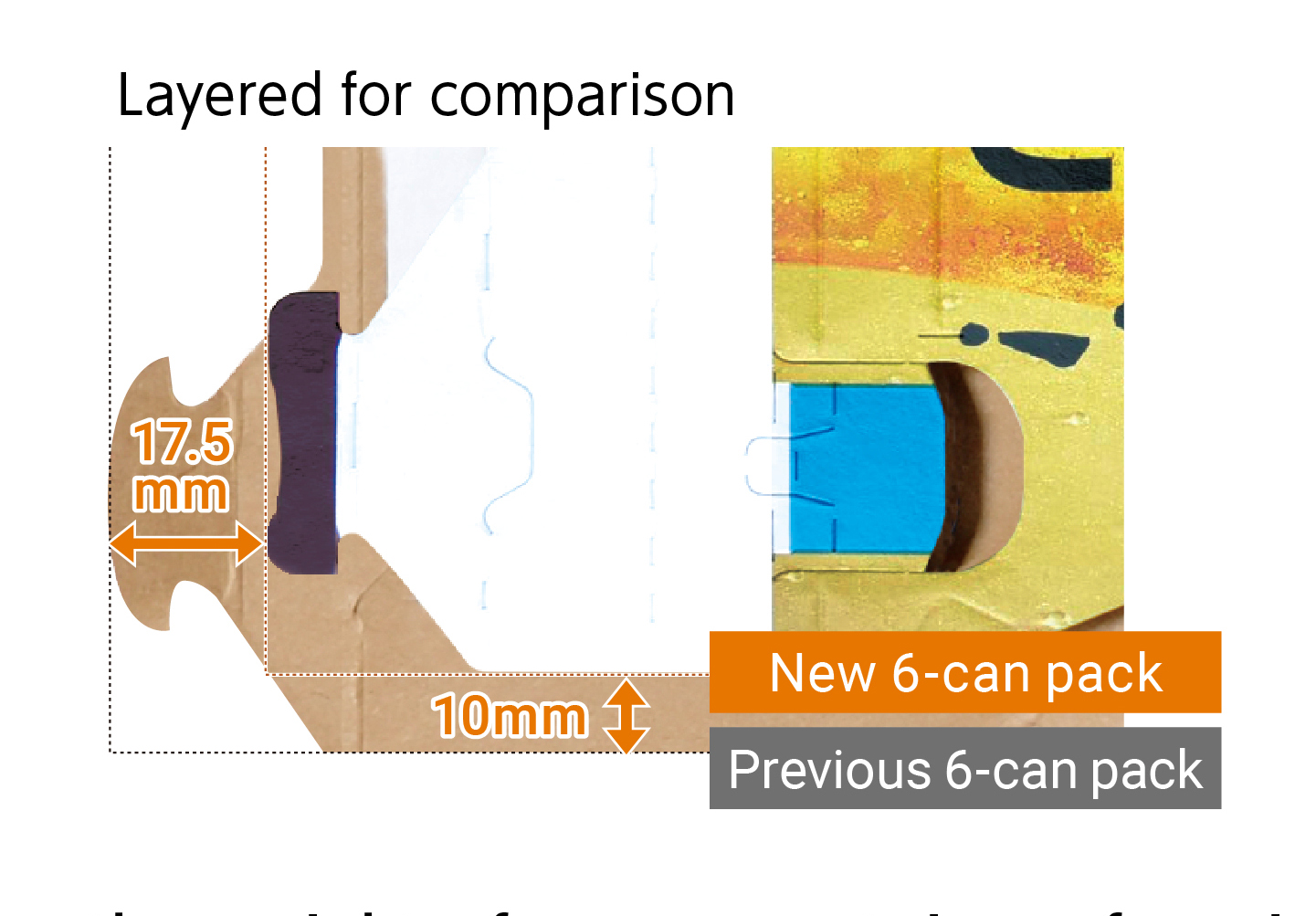

6-can pack

We have incorporated innovations into various parts of the 6-can pack to make it more lightweight, as well as achieving ease of carrying and removing from the shelf. For example, we have included a new cut-out section at the sides of the pack to match the can edge (Kirin patent), and use a “can bottom lock structure” to stabilize the bottoms of the can with paper. These innovations have resulted in a reduction in packaging materials of 4 grams, or 8%, per 500 ml 6-can pack, while improving the pack’s can-holding power.

Reducing the weight of paper containers for wine

Since March 2022, Mercian has reduced the weight of containers for wine that it sells. Mercian uses bag-in-box packaging with an inner bag inside an outer box for a total of five types of wine, namely FRANZIA (red, white, dark red) bag-in-box and FRONTERA (Cabernet Sauvignon and Chardonnay) wine-fresh servers. By reducing the weight of the outer box by approximately 25%, from 190g to 143g, we are able to reduce our use of paper resources by around 31t per year.

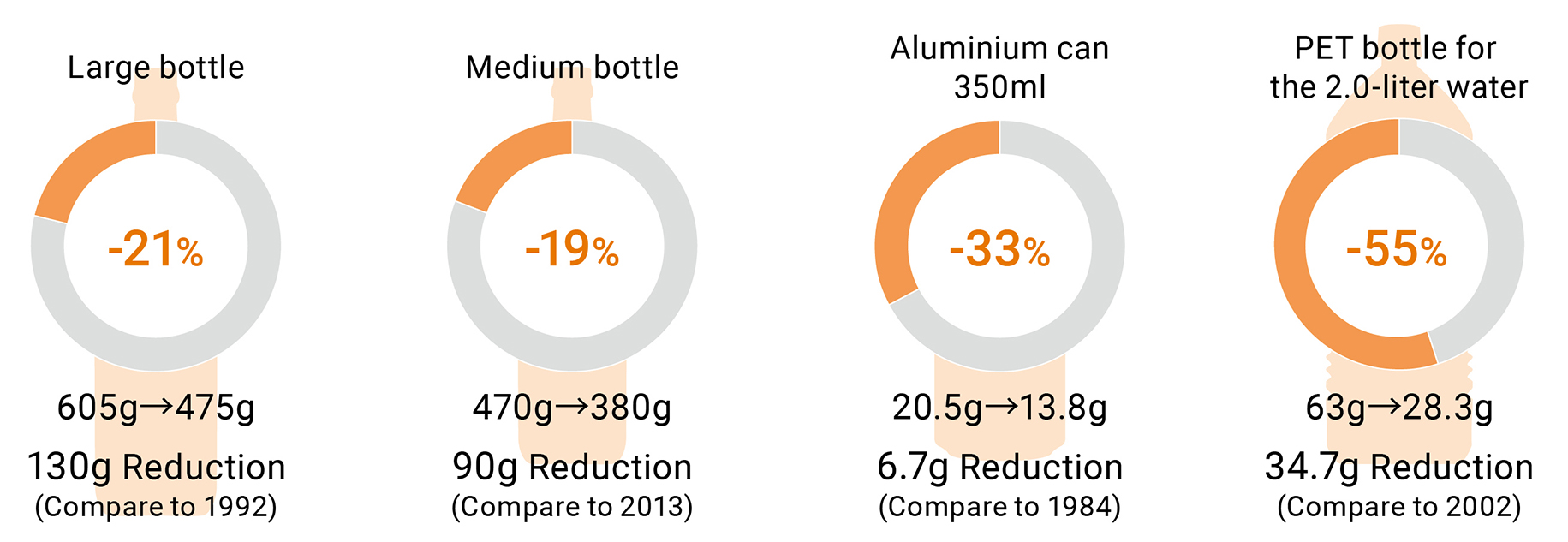

Reducing the weight of PET bottles for wine

In 2022, the Institute for Packaging Innovation developed a 720ml PET bottle for wine that is the lightest in Mercian’s history. We reduced the weight by 5g, from 34g to 29g. We expect the use of this bottle for all 720ml PET bottle products produced and sold by Mercian to reduce PET resin use by approximately 83 tonnes per year and GHG emissions by approximately 286 tonnes.

The lightweight PET bottle received the “46th Kinoshita Award for Packaging Technology.” This bottle won the award partly because we reduced resin use by approximately 15% while maintaining the “Bordeaux shoulder shape” and a “clean body shape,” as well as the fact that the Kirin Group's gas barrier coating technology, which uses DLC*1 film, can keep wine fresh for a long period of time.

- Abbreviation for Diamond-Like Carbon (Patent No. 4050648, etc.), a technology that forms a thin film of carbon on the inside of PET bottles to inhibit the permeation of oxygen, water vapor, carbon dioxide and other gases

Use of roll labels

Since September 2020, Kirin Beverage has used “roll labels” on some PET bottle products for sale in vending machines. There are two main types of label for PET bottled soft drinks: shrink labels and roll labels. We place shrink labels over bottles with a labeler in the filling plant, then apply heat to shrink the label. This means a certain thickness is required to prevent the label from bending. We do not use heat to shrink roll labels, instead attaching them by wrapping them around the PET bottle, which enables us to make the label thinner. For expanding the use of roll labels, we have been adding roll labelers to two Kirin Beverage factories starting from February 2023. Customers can easily remove the label by simply pulling the edge of the label, making it easier to sort trash, and thereby promoting recycling.The roll labels are used mainly for products sold exclusively in vending machines (in combination with shrink labels), such as Kirin Namacha, Kirin Gogo-no-Kocha Oishii Muto, Kirin Loves Sports, Kirin Amino Supplement C, and Kirin Tennensui Natural Mineral Water.

Lightest PET bottles for water produced in Japan

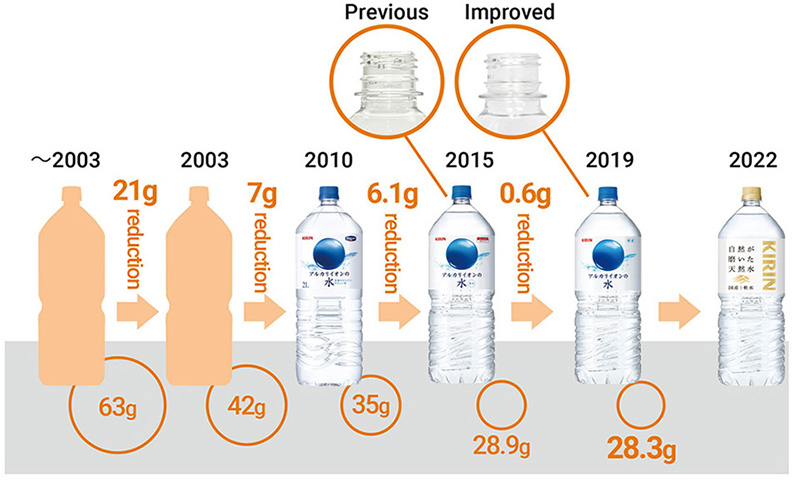

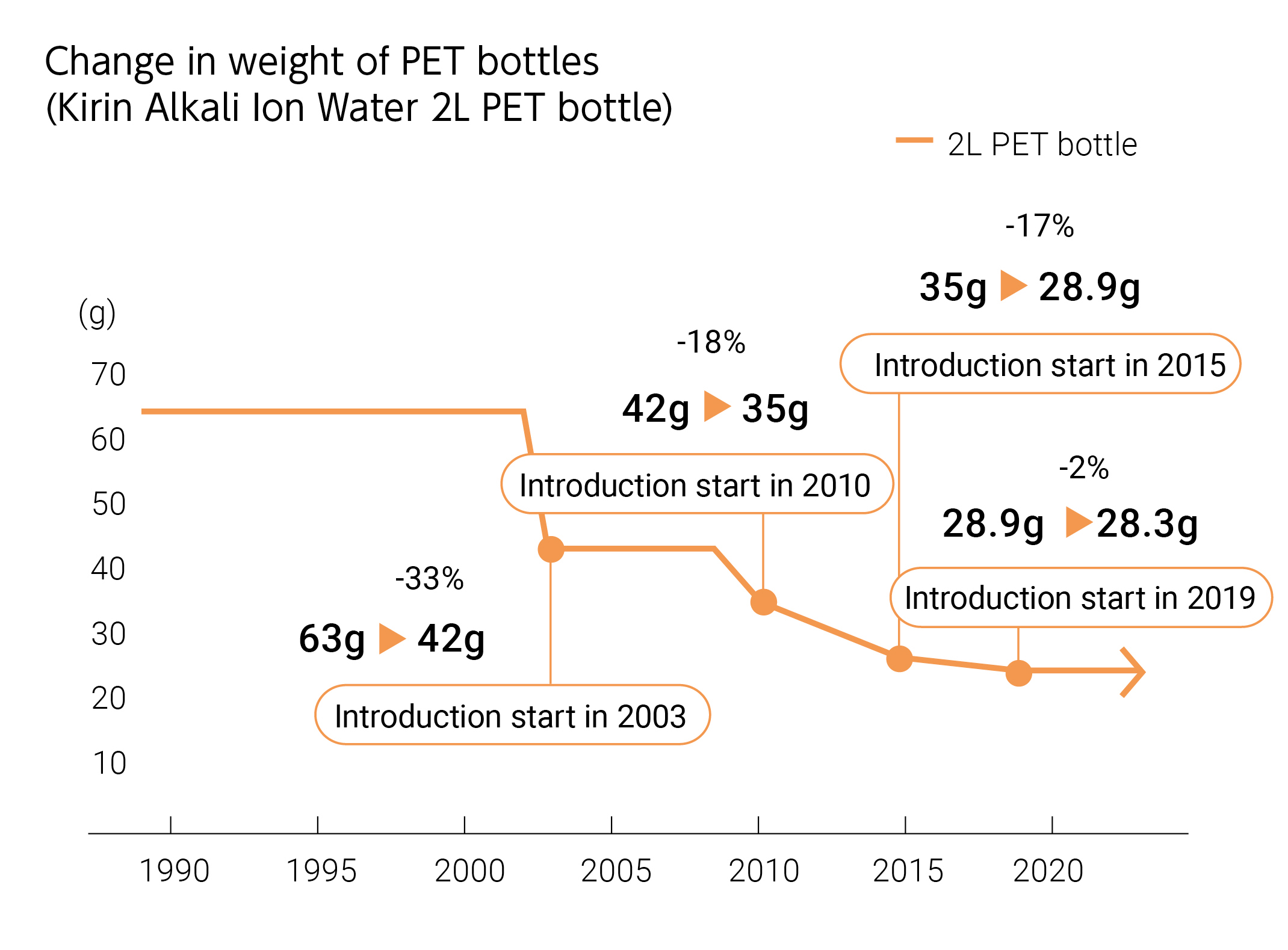

The Institute for Packaging Innovation has developed and put into practical use the lightest 2L PET bottle for water produced in Japan, at 28.3g.

We reduced the weight of the 2L PET bottle from 63g prior to June 2003 to 28.9g in 2015, and further reduced the weight in April 2019 by improving the bottle’s screw top, including making the screw threads narrower and the screw portion shorter, thereby making achieving the lightest such PET bottle produced in Japan and putting it into practical use.

These efforts will result in annual reductions of PET resin use of approximately 107 tonnes and GHG emissions of approximately 375 tonnes.

For some 2L and 1.5L large PET bottle products, such as Kirin Gogo-no-Kocha and Kirin Nama-cha, we reduced the weight by approximately 16%, from 38.2g to 32.2g, by improving the molds of preforms used to make the PET bottles. We have been gradually introducing these bottles starting from products manufactured in December 2020. These efforts will result in annual reductions of PET resin use of approximately 439 tonnes and GHG emissions of approximately 1,515 tonnes.

- Product photographs are current as of June 2023 or the time that events occurred.

No label product

Since March 2021, we have been selling Kirin Nama-cha No Label 6-Pack and Kirin Nama-cha Hoji Sencha No Label 6-Pack at general merchandise stores nationwide, as well as Kirin Nama-cha No Label and Kirin Nama-cha Hoji Sencha No Label exclusively online. In May 2022, we expanded our range of no label products with the launch of Kirin Gogo-no-Kocha Oishii Muto (sugar-free) No Label and Kirin FIRE ONE DAY Black No Label exclusively online. On April 25, 2023, we began sales of a new product, Kirin Shizen-ga-Migaita Natural Water No Label, on e-commerce only.

In June 2022, we will begin test sales of Kirin Nama-cha No Label with Paper Sticker at some general merchandise stores in the Tokyo metropolitan area. By attaching small paper stickers that provide the required information, we are able to sell individual products at the store without conventional labels.

We have developed a recycling-compatible direct printing technology that can be directly printed on PET bottles in August 2023.

Shortening of labels and packaging materials

We have shortened the label on packaging for the 600ml Kirin Namacha and Kirin Nama-cha Hoji Sencha that we released in 2022. In addition to reducing the size of the label and making it thinner by switching to roll labels, this will result in annual reductions of resin use by approximately 180 tonnes and GHG emissions of approximately 400 tonnes.

We have made the paper packaging materials for the 525ml and 600ml products in the six-bottle packs of no label products shorter than those of the products we launched in 2021, thereby reducing paper consumption. We also use FSC-certified paper for packaging materials, and display a label of our certification.

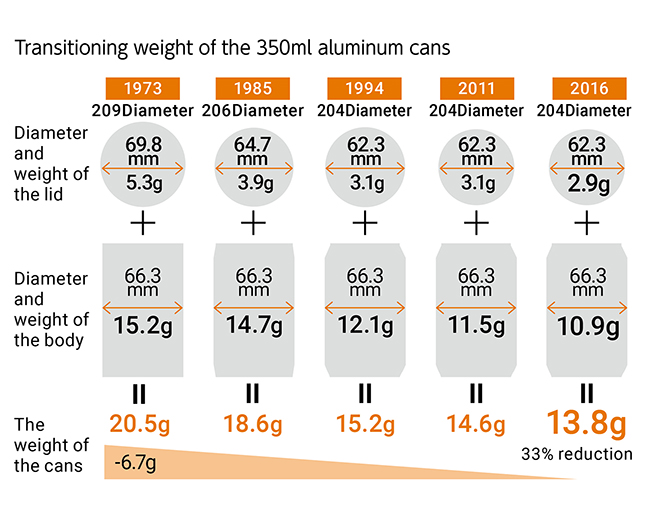

Reducing the weight of aluminum cans

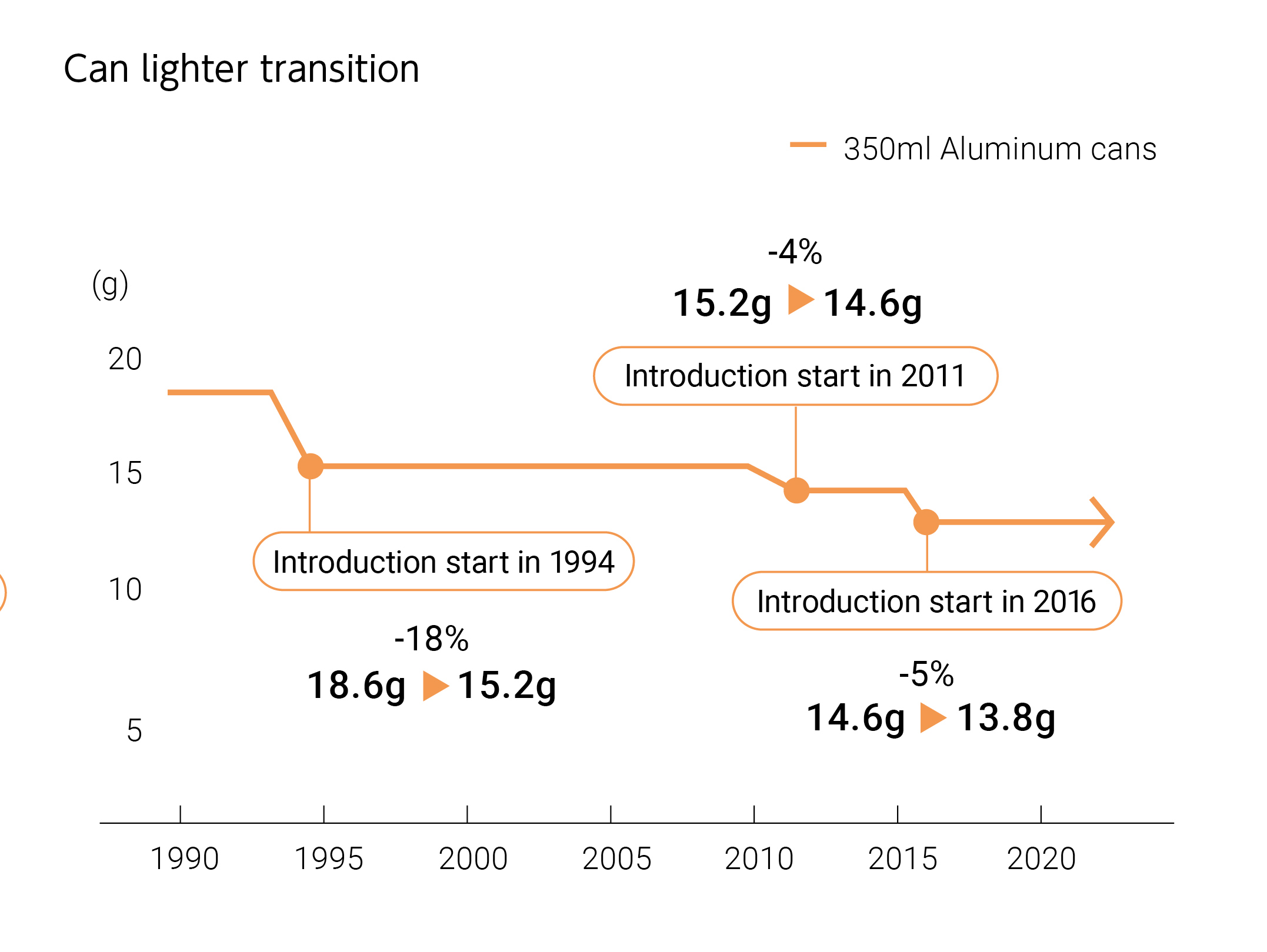

By reducing the diameter of aluminum beer can ends and narrowing the top and bottom edges of the can body to reduce the weight of the can, as well as thinning out the walls of the can body, for our 350 ml aluminum cans, we have achieved a weight reduction of approximately 29% for our 204 diameter can end compared with the 209 diameter can end in 2011. Working with materials manufacturers, we developed an aluminum can with thinner can ends and body in 2016. We have reduced the overall weight of the can by approximately 5% (0.8 g) from 14.6 g to 13.8 g. This represents a weight reduction of 33% (6.7 g) from the 209diameter can end. Weight reduction is necessary for both steel and aluminum cans, but aluminum in particular requires a large amount of electricity for smelting, so weight reduction contributes significantly to the reduction of Scope 3 GHG emissions.

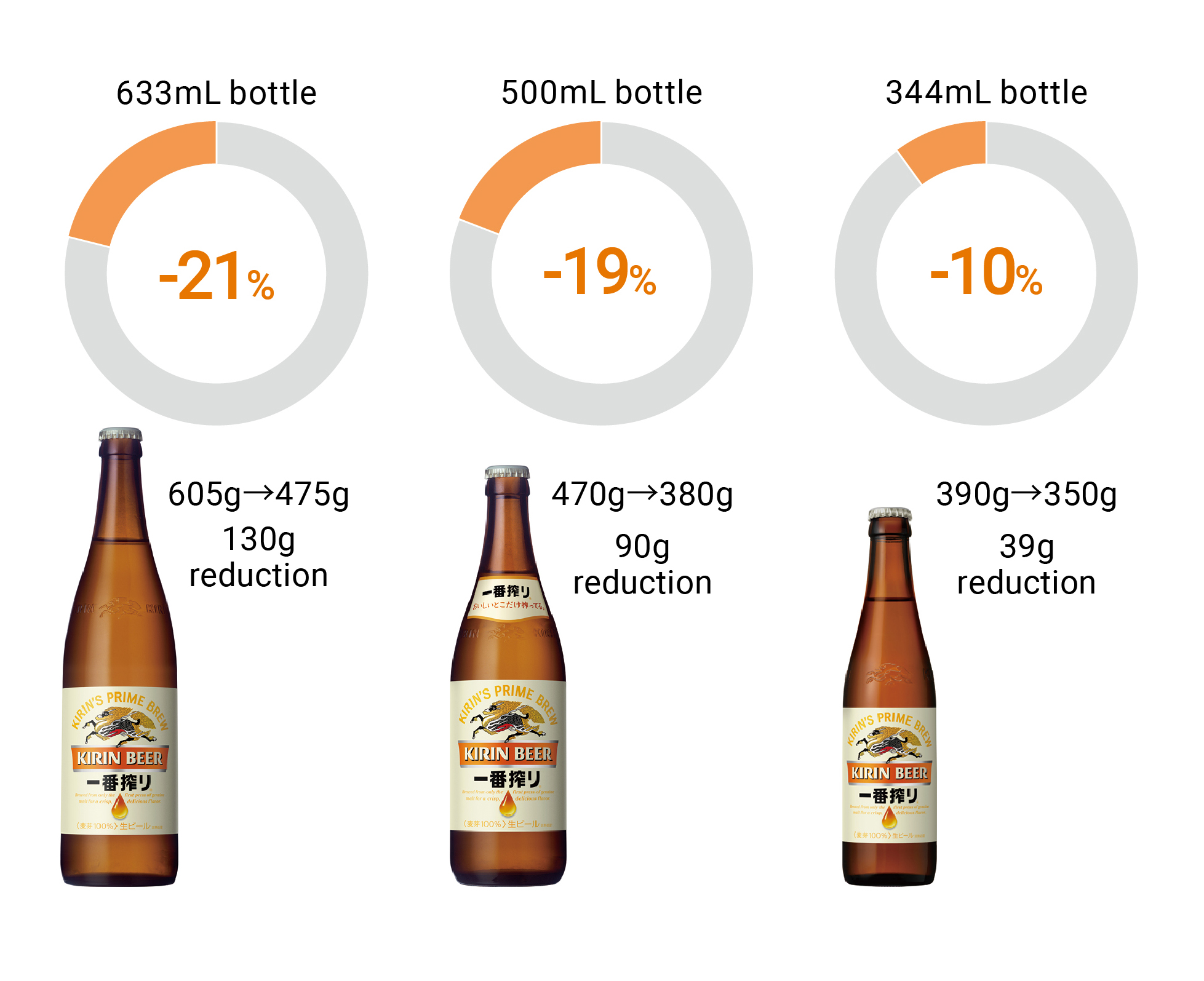

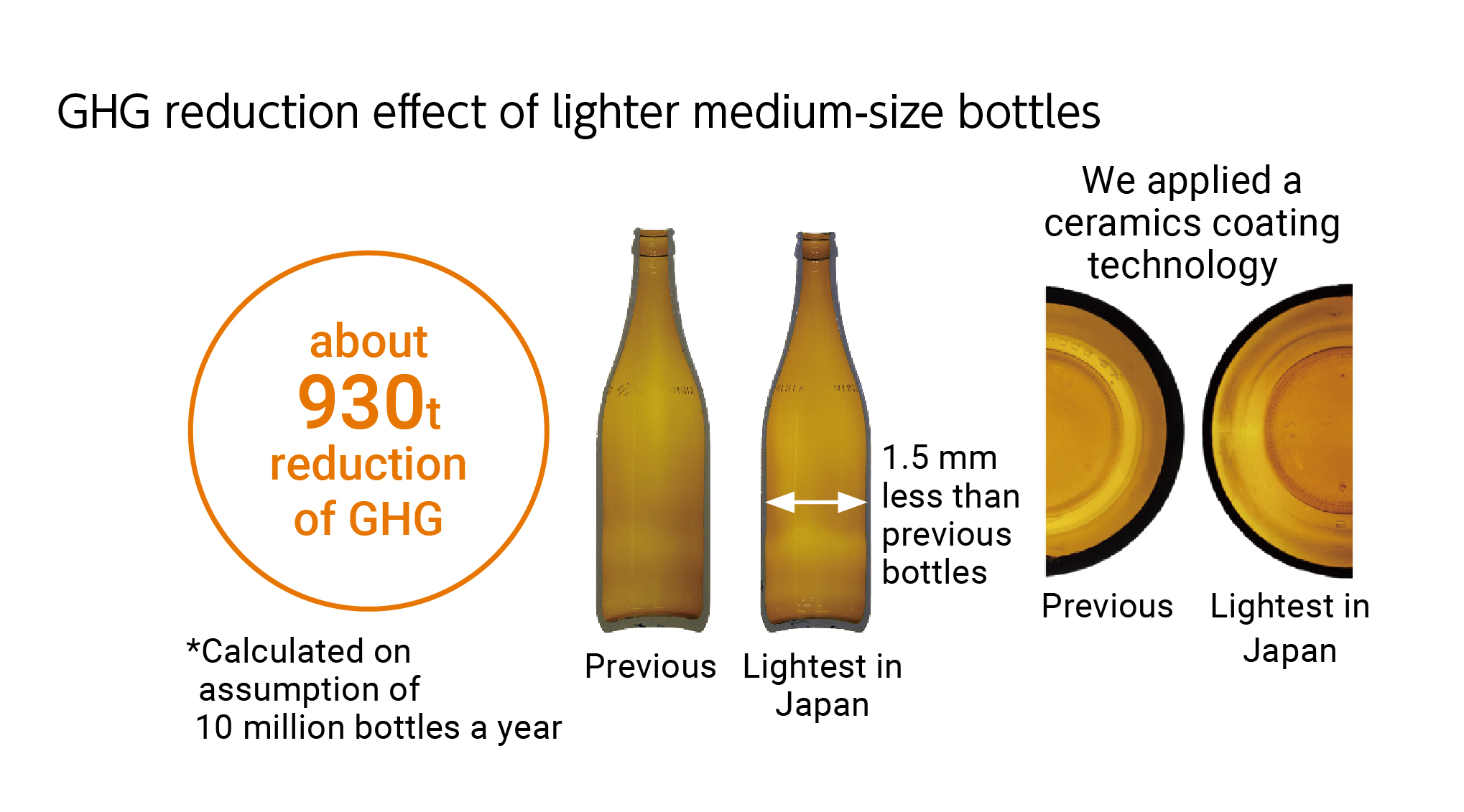

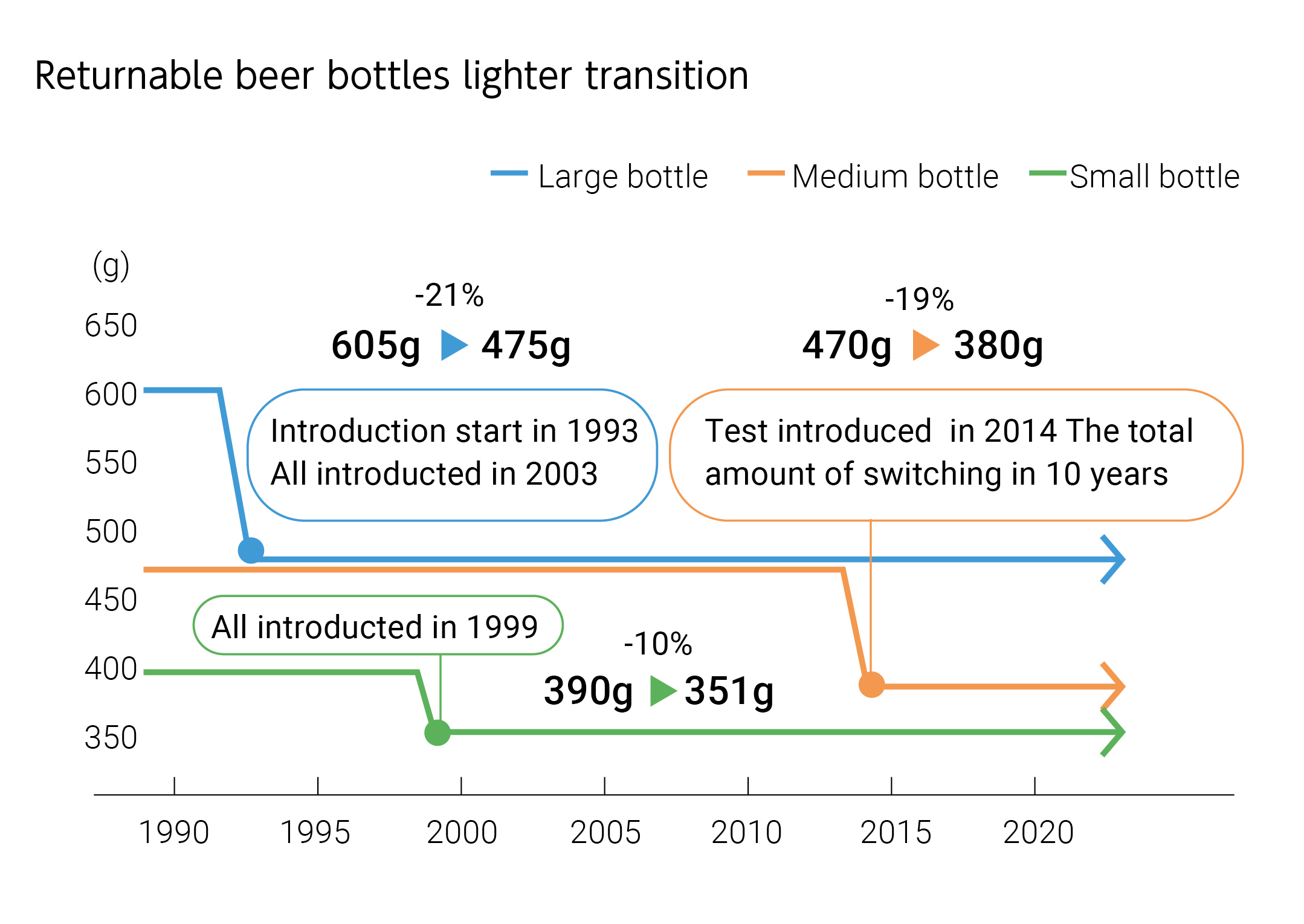

Lighter returnable glass bottles in Japan

Our returnable glass bottles for beer are the lightest weight returnable bottle produced in Japan in all sizes (large, medium, and small). As well as being light in weight, returnable glass bottles need to be durable enough to maintain their returnable functionality and strong enough to ensure consumer safety and security. To meet this challenge, the Institute for Packaging Innovation created the lightest returnable glass bottles by making excellent use of innovations such as a ceramic coating that forms a thin film on the bottle’s outside surface, an impact-resistant shape design, and a bottle mouth design that meets the conflicting requirements of being easy to open and able to be sealed tightly and that is also strong enough not to chip.

Reuse

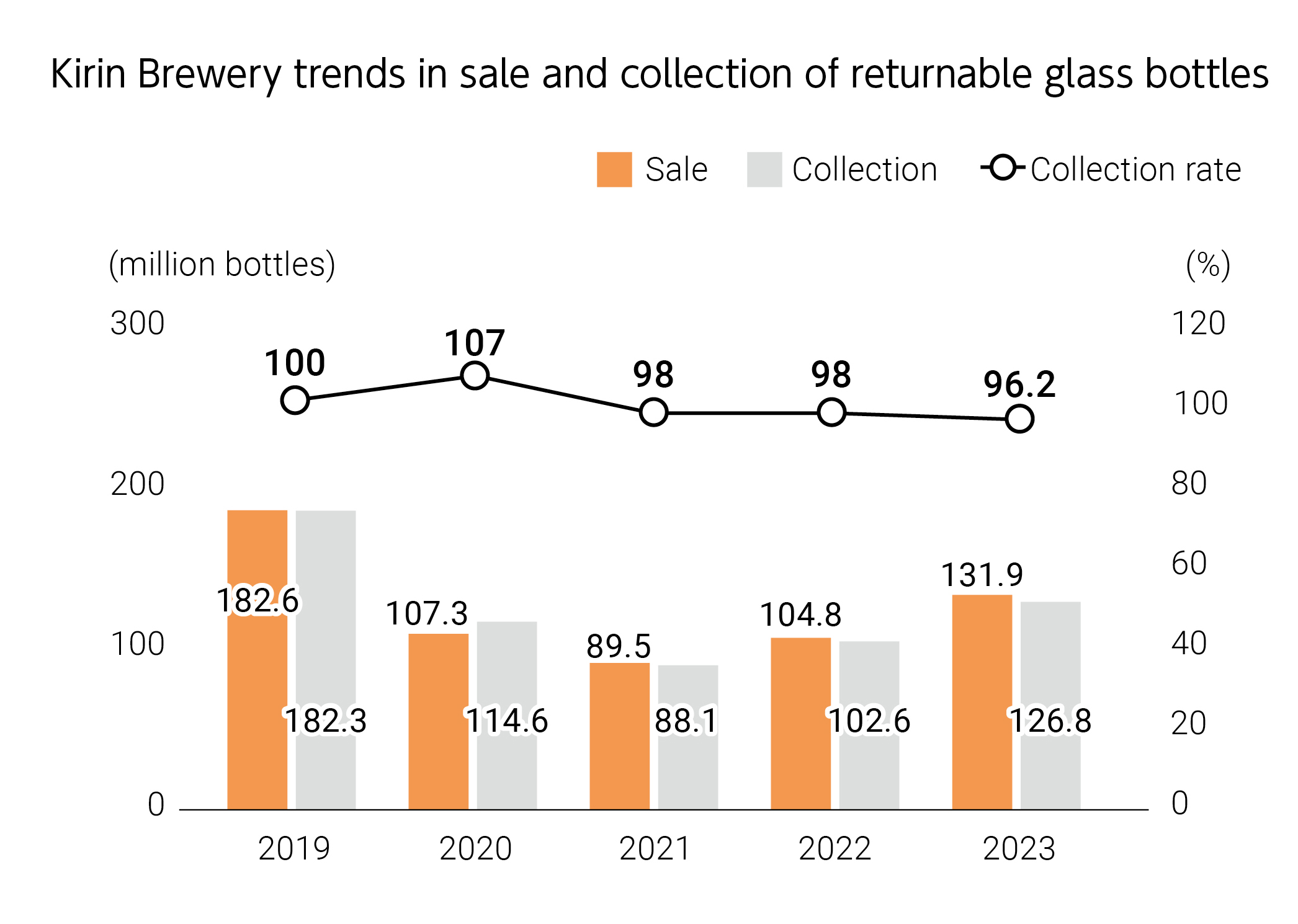

Reuse of glass bottles

In Japan, people have collected and reused glass bottles over and over since the Meiji Era (1868-1912), long before the word “3R” was coined.

We wash returnable glass bottles that come back to the plant thoroughly inside and out to make them as clean as a new bottle. After stringently checking the bottles for scratches and cracks with an empty bottle inspection machine, we put them back into product service and fill them with beer. When handled carefully, returnable glass bottles last for an average of about eight years. This means they are used around 24 times. When bottles have small scratches or fine cracks or are too old to be of service any longer, we crush them and turn them into a material called cullet, which we use as the raw material to make new bottles.

Recycle

Recycling of PET bottles

The Kirin Group promotes the recycling of PET bottles as a member of the Council for PET Bottle Recycling. Under the Council’s Fourth Voluntary Action Plan (FY2021-FY2025), we are working toward a target recycling rate of at least 85% (base year: FY2004). In 2021, our recycling rate was 86.0%, achieving the target. We are also expanding demonstration trials for the voluntary collection of used PET bottles in partnership with companies and public administration.

Recycling of glass bottles

We turn old returnable glass beer bottles that can no longer be reused and one-way bottles which are used only once into cullet, for use primarily as the raw material for making new glass bottles. We are pursuing uses for cullet made from colored glass, which cannot easily be reused for glass bottles. We are expanding potential ways to recycle this material for other applications, including in building materials such as tiles and blocks and road paving materials.

Recycling of cans

The Kirin Group is pursuing the adoption of aluminum cans that use a high rate of recycled metal. We have also joined the Japan Aluminum Can Recycling Association, and we are providing assistance for the collection of used aluminum cans as a way to promote their recycling. Can manufacturers recycle aluminum cans discarded at breweries and use them as 100% aluminum cans for beer.

Promotion of recycling in Australia and New Zealand

Lion has established the “Sustainable Packaging Strategy” to promote recycling. The Lion's Sustainable Packaging Project Steering Group, established to promote this strategy, has set the following goals and is working with the Australian Packaging Covenant Organisation (APCO) to achieve them.

As glass accounts for the highest proportion of Lion's material inputs, Lion is working closely with its supplier to increase the recycled content of bottles.

Australia has Container Deposit Schemes in six of its eight states, and both remaining states have announced that they will implement this system in the future. Victoria and Tasmania are expected to commence schemes in 2023. Lion plays an important role in Australia's Container Deposit Schemes. For example, in South Australia and Northern Territory, Lion holds a majority of the shares of Marine Stores, a collection coordinator that aggregates collected materials for reuse and recycling. Lion also participates in Exchange for Change (EfC), a joint venture that coordinates the New South Wales and the Australian Capital Territory Container Deposit Schemes.

In Queensland and Western Australia, Lion participates in the administration and operation of Container Deposit Schemes as a member of the Container Exchange (QLD) Limited (CoEx) and WA Return Recycle Renew Limited (WARRRL), which were established and appointed as Producer Responsibility Organizations. Lion is a member of the nonprofit entities VicRecycle and TasRecycle, which intend to submit proposals to act as the coordinators of the Container Deposit Schemes in Victoria and Tasmania.

In New South Wales almost nine billion bottles and cans have been returned in less than four years of the scheme being in place, and there are currently 621 return points operating. The Queensland Container Deposit Scheme has been operating less than three years with nearly 5.4 billion containers returned and 341 return points in operation. The Western Australian Container Deposit Scheme commenced in October 2020, and almost one billion containers have been returned. The South Australian scheme has been operating for over 40 years and recent reports stated the return rate of beverage containers sold is approximately 76.9%. In 2022, the South Australian government is considering improvements to modernize the scheme and further increase the rate of return. Lion is working with the state government to support the development and implementation of improvements. In the Australian Capital Territory, more than 270 million containers have been returned and recycled since the scheme began operating in December 2017. The Northern Territory scheme had a total return rate of 72% of containers sold.