It doesn’t end with recycling. Kirin’s responsibility to recycle resources for the future

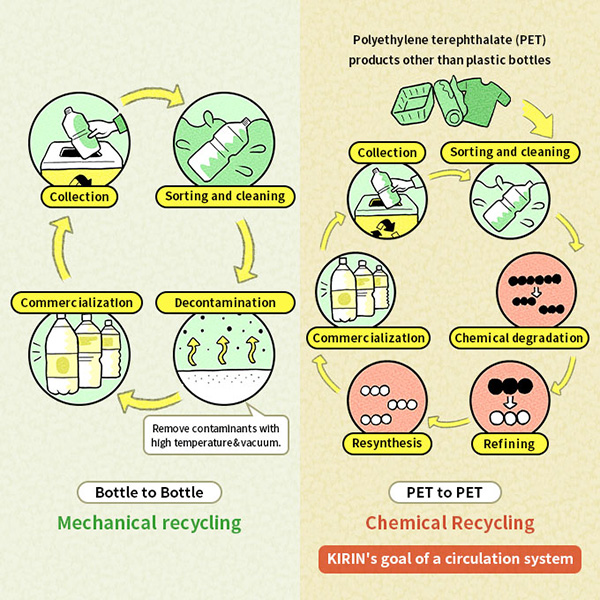

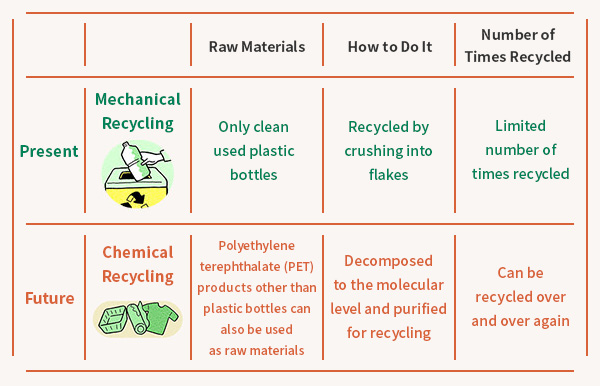

Kirin is committed to bottle-to-bottle recycling, in which used PET bottles are reborn as beverage bottles. With the R100 PET Bottle, which is made from 100% recycled PET resin, we are promoting the realization of horizontal recycling by utilizing mechanical recycling technology. We are also taking on the challenge of developing chemical recycling technologies that can regenerate materials at the molecular level, thereby expanding the possibilities of resource recycling.

In paper containers, we actively use FSC®-certified paper for our cartons and packaging to conserve forest resources. We had achieved 100% use of FSC®-certified paper by 2020.(FSC®004238)

Effective use of limited resources and manufacturing that does not burden nature.

Under the Kirin Group Environmental Vision 2050, Kirin continues to take on the challenge of making a positive impact on the environment, aiming to realize a society in which recycling is the norm.

Why work on developing sustainable containers and packaging?

Containers and packaging are necessary to deliver products to customers while maintaining product quality. On the other hand, excessive use of materials for containers and packaging, as well as improper disposal, can lead to damage to natural capital.

To address the various challenges posed by containers and packaging, we are committed to the sustainable use of containers and packaging and practice the 3Rs (reduce, reuse, recycle) by reducing the amount of plastic and paper used, promoting recycling, reducing weight, and introducing reusable containers.

We contribute to a sustainable, recycling-oriented society by aiming to create containers that are not used and discarded but rather reborn again.

Promoted adoption of R100 PET Bottles and practical application of chemical recycling

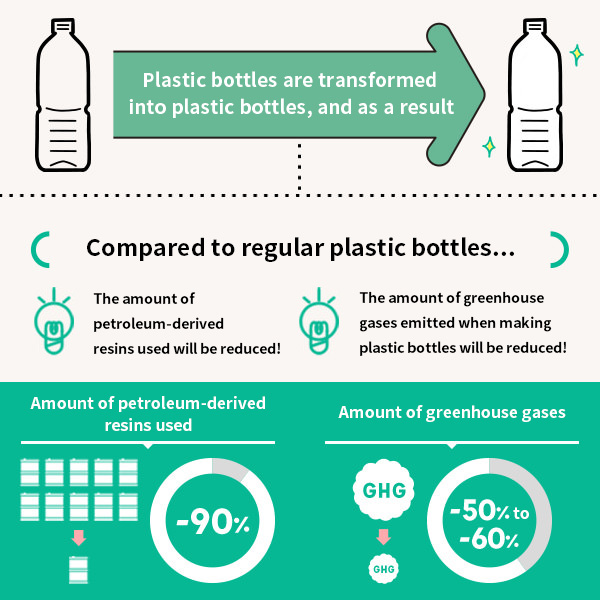

The Kirin Group is expanding its use of R100 PET Bottles, which are made from 100% recycled PET resin. This is an environmentally friendly bottle that reduces petroleum-derived resin by 90% and greenhouse gases by 50-60%.

"R100" is achieved through horizontal recycling, in which properly sorted PET bottles are reincarnated as bottles. Currently, the "R100" is adopted for products such as Nama-cha, and the mark is on the package.

Accelerating Plastic Recycling with Chemical Recycling Technology

Horizontal recycling is known as mechanical recycling, but Kirin is also working on the practical application of chemical recycling, which breaks down and recycles at the molecular level.

Chemical recycling, which makes it possible to recycle PET products other than PET bottles, as well as colored bottles that were difficult to recycle with conventional mechanical recycling, can be recycled over and over again. It plays a very important role in achieving a sustainable future.

Reinforcement of the plastic bottle collection system and improving the recycling environment

As we promote various R&D and initiatives to promote recycling of containers, we are also focusing on improving the collection system and the environment required. In particular, as PET bottles are a resource when separated, it is important for consumers to cooperate in sorting and collecting PET bottles.

However, about 30%* of foreign matter is mixed in the recycling bins next to vending machines, making sorting time-consuming and costly. In response to these issues, from 2022 we have been introducing recycling boxes with a new function that reduces foreign matter contamination to improve the quality of collection.

In cooperation with the PET Bottle Recycling Promotion Council, we also worked to achieve a recycling rate of 85% or higher, and had achieved 85.0% by 2023.

As for overseas, Lion, a Group company in Australia, is strengthening collection through a container deposit system. The company also participates in the operation of the system in each state, supporting the resource recycling system.

-

*Source: Japan Soft Drink Association 2019 Activity Report

Achieved 100% use of FSC® certified paper –to protect future forests and society

-

*Some of the product photos are from the time of the event and may not be the most recent ones.

Kirin has been actively adopting FSC®-certified paper for its paper packs and packaging with the aim of conserving forest resources, and had achieved 100% usage of FSC®-certified paper by 2020.

In 2022, the target will be expanded to include Kyowa Kirin, Kyowa Hakko Bio, Lion, and Koiwai Dairy Products, with the goal of switching to FSC®-certified paper and recycled paper by 2030.

Through the sustainable use of paper resources, we will continue to take on the challenge of protecting the forests and society of the future.

Also developing environmentally friendly packaging using beer byproducts

Beer lees are a byproduct of the beer brewing process. This byproduct, which in the past was sometimes discarded, is now being utilized by Kirin as a new resource. One example is the use of this byproduct as a packaging material for cosmetics in collaboration with FANCL.

We will create new value by taking what comes from food and utilizing it in a different way. With the idea of making the most of limited resources, we will continue to manufacture environmentally friendly products.