Ensuring Product Safety and Reliability in the Food & Beverages Domain

Approaches in Our Food & Beverages Business

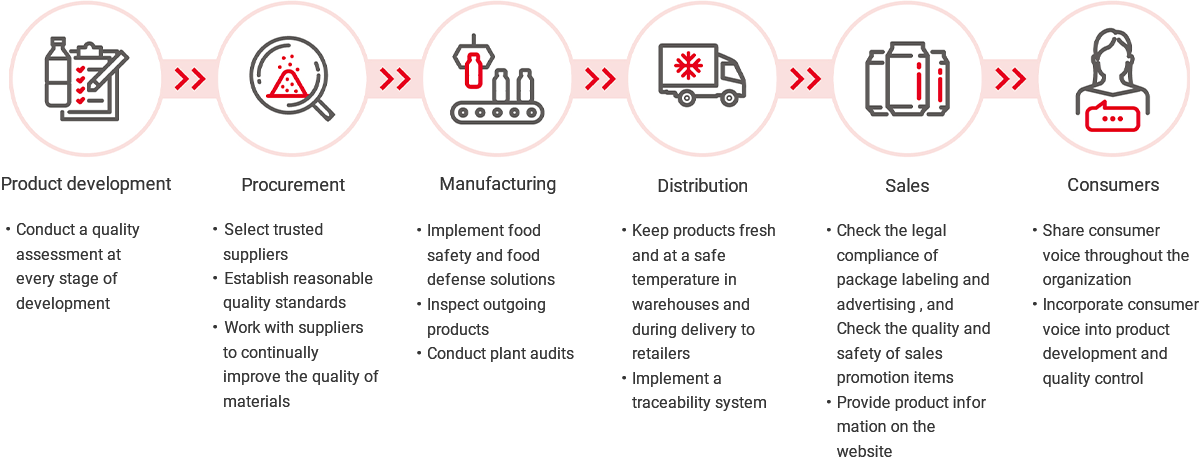

Our Quality Assurance Practices in the Value Chain in Japan

Based on the Kirin Group’s Quality Policy and Action Principles, we have implemented an end-to-end quality assurance system that applies to every step of the value chain—from product development through to the delivery of products to consumers.

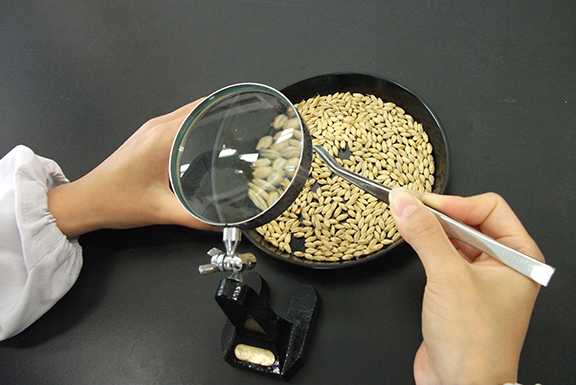

Safety of Our Materials

The Kirin Group has established guidelines for ensuring the safety of materials (ingredients, packaging containers, etc.) to ensure the safety of raw materials we employ.

We regularly and routinely collect risk information related to safety information from both domestic and international government agencies and research institutions, and when using and adopting raw materials, we refer to and use this information to confirm their safety and determine standards for safety.

We also have a system in place that allows us to take appropriate measures and actions as necessary based on risk information related to safety even after raw materials are adopted.

Radioactive Substances

Regarding radioactive substances, we conduct product analysis at a frequency determined by each plant.

In addition, we routinely check government monitoring information, etc. on water and agricultural products used as raw materials.

Genetic modification

We comply with the Food Sanitation Act regarding the use of genetically modified agricultural products and processed foods made from them.

Furthermore, we do not use genetically modified raw materials that are required to be labeled under the GMO labeling system.

Pesticide Residues

The Kirin Group ensures that the raw materials used in its products are safe and meet the residue standards of the Food Sanitation Act through the following methods, etc.

-

Confirmation of management status including analysis results of agricultural chemical residues at raw material suppliers

-

Confirmation of information on domestic and international violations for similar raw materials

-

Collection of other risk information on agricultural chemical residues, etc.

Food Additives

We evaluate food additives approved by the Food Sanitation Act and use according to their purposes. In addition, we use food additives in accordance with the standards of the Food Sanitation Act.

Allergens

We obtain allergen information on the raw materials we use and properly manage them to ensure that there is no contamination with allergens other than those indicated on the product.

Specified ingredients are displayed not only for foods that are required to be labeled, but also for alcoholic beverages that do not have labeling requirements.

Group Companies and Plants Certified with Food Safety Management Standards

Many of the plants operated by Kirin Group companies are certified with the Global Food Safety Initiative (GFSI)* recognised international standards for food safety management systems, or ISO 22000. To ensure the safety of all food and beverage products we manufacture and market, all Kirin Group plants will be certified by 2024.

As part of the maintenance of quality management and food safety management system, we ensure the effectiveness of our system through annual renewal or maintenance audit by external certification institutions.

Additionally, as one of the cross-departmental functions of the Kirin Holdings Quality Assurance Department, we regularly conduct internal audits of quality at Group operating companies.

-

*The Global Food Safety Initiative (GFSI; the Coalition) is a CEO-led Coalition of Action from The Consumer Goods Forum, bringing together retailers and manufacturers and an extended food safety community to help oversee food safety standards for businesses and help provide access to safe food for people everywhere.

Source : My GFSI - WHO WE ARE - Overview https://mygfsi.com/who-we-are/overview/

Main Certification Acquired at Key Manufacturing Sites

As of January 1, 2025

| Operating Company Name | Main Products | Certifications Related to Quality Management System | Certifications Related to Food Safety Management System | ||

|---|---|---|---|---|---|

| ISO9001 | Certification Name | Number of Certified Sites | Number of Main Production Sites | ||

| Kirin Brewery Company, Limited | Alcoholic beverages | ○ (Corporate departments) | FSSC22000 | 10 | 10 |

| Kirin Beverage Company, Limited | Non-alcoholic beverages | ○ (Corporate departments) | FSSC22000 | 3 | 3 |

| Mercian Corporation | Alcoholic beverages | ○ (Corporate departments) | FSSC22000 | 3 | 3 |

| Kyowa Hakko Bio Co., Ltd. | Food materials | ○ (BIO KYOWA) | FSSC22000 | 3 | 3 |

| Koiwai Dairy Products Company, Limited | Dairy products | JFS-C | 2 | 2 | |

| LION PTY LTD | Alcoholic beverages | ○ | FSSC22000 | 4 | 4 |

| Interfood Shareholding Company (IncludingVIETNAM KIRIN BEVERAGE CO., LTD. Sites) |

Non-alcoholic beverages | ○ | ISO22000 | 2 | 2 |

| Four Roses Distillery, LLC | Alcoholic beverages | SQF | 1 Expected to be acquired at one unacquired location by the end of 2027 |

2 | |

| Coca-Cola Beverages Northeast, Inc. | Non-alcoholic beverages | ○ | FSSC22000 | 2 | 2 |

| Blackmores Group | Dietary Supplements | SQF | 2 | 2 | |

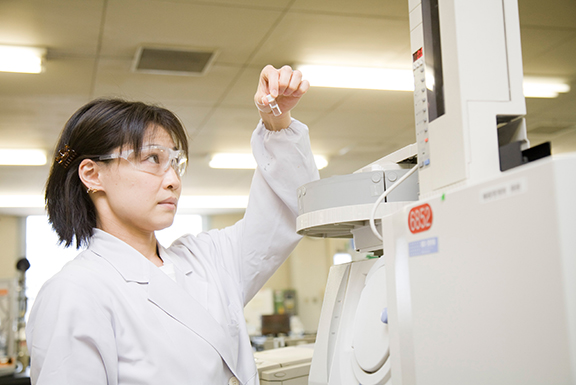

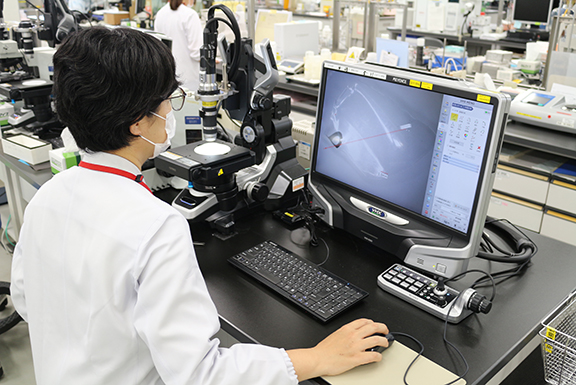

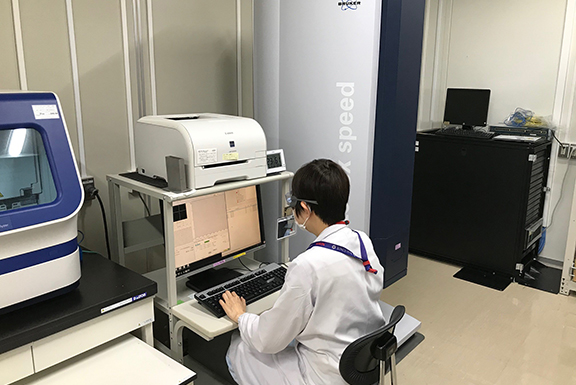

Food Safety and Quality Assurance Center

The Food Safety and Quality Assurance Center of Kirin Holdings conducts tests and analyses for Kirin Group companies to ensure quality and safety across the value chain.

The Center consolidates groupwide knowledge and resources related to quality assurance and works with Group companies to conduct sophisticated and comprehensive quality assurance.

Its responsibilities include analyzing for safety not only raw materials and finished products sourced and manufactured by Group companies but also products under development, products returned by consumers for quality reasons, and manufacturing processes. It also develops and upgrades analysis and evaluation methods, and checks and improves the level of accuracy of testing procedures followed by value-chain actors and suppliers.