Quality management

Kirin Group Global Quality Management Principle

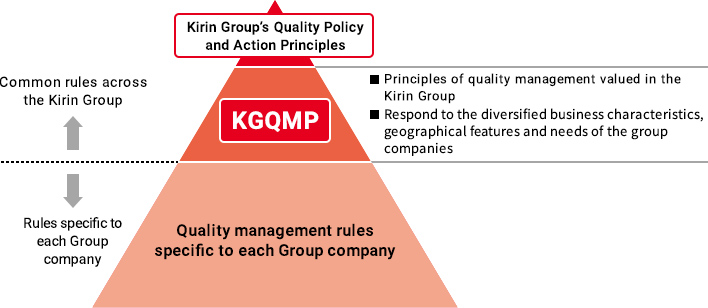

The Quality Assurance Department of Kirin Holdings has established the Kirin Group Global Quality Management Principle to promote the quality policy and action principles of the Kirin Group and a high level of quality management by Group companies.

This principle is the essence of quality management that the Kirin Group’s entire value chain, from raw material procurement, development, manufacturing, and distribution to the delivery of products and services to customers. The principle is reflected in the quality management systems of each Group company, leading to products and services of solid quality.

Kirin Group Global Quality Management Principle (excerpt)

-

Establish a quality management system and continually improve it

-

Appoint a quality management manager

-

Acquire necessary resources for quality management

-

Ensure legal compliance

-

Implement contractor management

-

Maintain communication with consumers

-

Establish quality requirements for licensees

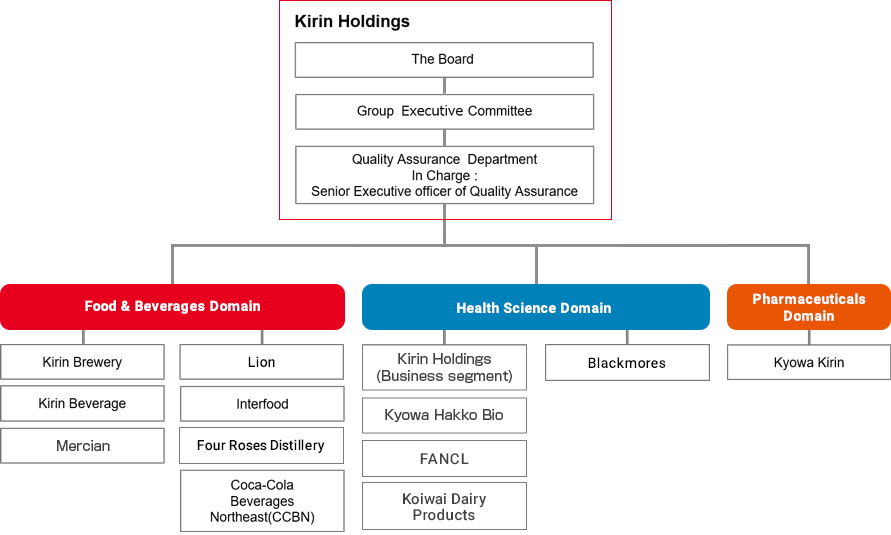

Governance Structure for Quality Assurance

Each Kirin Group company implements autonomous quality assurance activities based on the Kirin Group’s Quality Policy and Action Principles and KIRIN group Global Quality Management Principle.

In order to promote autonomous quality assurance activities at each company, the Quality Assurance Department of Kirin Holdings holds individual dialogues with each of the 13 major Group every year.

The dialogues with each company are reported to the Board meeting every year after discussion by the Group Executive committee as necessary.

In order to understand the quality assurance status across various domains and areas, Kirin Holdings has established common indicators and individual indicators for each group company, creating a system that enables the Quality Assurance Department to understand not only the status of the group as a whole but also the status specific to each company.

- Lion Pty Ltd.

- Interfood Shareholding Company

- Four Roses Distillery, LLC

- Coca-Cola Beverages Northeast, Inc.

- Blackmores Group

Basic Policy on Disclosing Information Regarding the Safety of Our Products and Services

-

1.We collect up-to-date information regarding the safety of our products and services.

-

2.When we receive a report of a safety issue with a product or service, we will collect more information regarding the reliability and implication of the report.

-

3.We analyze and scrutinize the collected information scientifically, using the full range of the Kirin Group’s technology and organizational assets.

-

4.If the analysis validates the report and finds that the product or service in question might affect consumers’ health, we will disclose it to the public immediately.

-

5.If we determine that there is a probability that the product or service in question might be harmful to consumers’ health, we will stop marketing it, recall it, or take whatever action is necessary voluntarily.

How we deal with incidents that affect the safety and Reliability of our products and services

When a quality-related incident is reported to us, we take immediate action in accordance with the Group Crisis Management Manual, putting consumers’ health and safety ahead of anything else.

As a first step, the Kirin Group company that marketed the product in question establishes an internal crisis management taskforce, through which information is shared among the president, officers, and other relevant parties within the company, and relevant information is provided to the public and regulatory authorities to prevent a health problem from affecting a larger population.

The taskforce works with the Group Risk and Compliance Committee and other relevant departments to keep track of the incident, analyze the situation, and develop an action plan based on a worst-case scenario. After taking initial responsive action, the taskforce coordinates with other departments in implementing preventive measures against the recurrence of similar incidents.

Quality Management Training Programs

The Quality Assurance Department of Kirin Holdings leads regular annual training programs related to quality.

| Training Program | Content | When | Intended for | Programs Held in Past 3 Years | ||

|---|---|---|---|---|---|---|

| 2022 | 2023 | 2024 | ||||

| Executive(Quality Assurance)message in Quality-Drive Month | Messages will be posted from the officer responsible for quality assurance on the internal intranet, and awareness of quality will be enhanced | Every November | All Kirin Group employees | ○ | ○ | ○ |

| Quality training | Participants will understand the importance of quality and be conscious of the fact that each individual is responsible for quality | Every November | All Kirin Group employees in Japan | ○ | ○ | ○ |

| At the time of joining the company | New employees | ○ | ○ | ○ | ||

| Every April or May | Newly-appointed executives | - | ○ | ○ | ||

| Training on appropriate advertising expression of food and beverage products with function claims | Participants will learn about rules related to packaging representations and various types of advertisements for foods with function claims | Every May or June | All Kirin Group employees in Japan | ○ | ○ | ○ |

Kirin Group has a Technical Talent Development Center that specializes in education and training, mainly for Group employees in technical roles. This center holds 148 courses(FY2024) per year, aimed at helping employees acquire various types of skills, communicate past serious quality incidents, etc.

| Names of Main Programs Related to Quality | Content | Programs Held in Past 3 Years | ||

|---|---|---|---|---|

| 2022 | 2023 | 2024 | ||

| Training course for internal auditors (ISO9001, FSSC22000) |

Participants will understand standards and criteria, and will learn skills that can be implemented in workplace internal quality audits | ○ | ○ | ○ |

| HACCP course | An understanding of HACCP frameworks is promoted based on FSSC22000 | ○ | ○ | ○ |

| Serious quality incident communication course | Participants will learn about previous serious quality incidents, and measures to prevent quality incidents from reoccurring and advance prevention measures will be thoroughly implemented | ○ | ○ | ○ |

| Achieving safety and reliability in the Kirin Group's Food & Beverages domain | Participants will deepen understanding of safety and reliability activities related to the Kirin Group's Food & Beverages domain | ○ | ○ | ○ |