Water Resources

Sustainable use of water resources

Water is an essential raw material for the Kirin Group and an indispensable utility for our operation such as cleaning production equipment. The Kirin Group runs its businesses in various regions in the world; Japan has abundant water resources whereas Australia has experienced severe water shortages many times in the past. We understand through the business experiences that water risks and water stress vary significantly between countries and regions. Since 2014, we have periodically surveyed quantitative water risks and stress of operation sites by using scientific tools and applied findings from the surveys to our business strategies. We run scenario analysis based on the TCFD recommendations to understand water risks in areas producing our agricultural raw materials and try countermeasures to the risks. We will go beyond just reducing water usage and try to identify and mitigate our impact on the natural capital of basins as a whole, collaborating with local stakeholders.

Main Activities

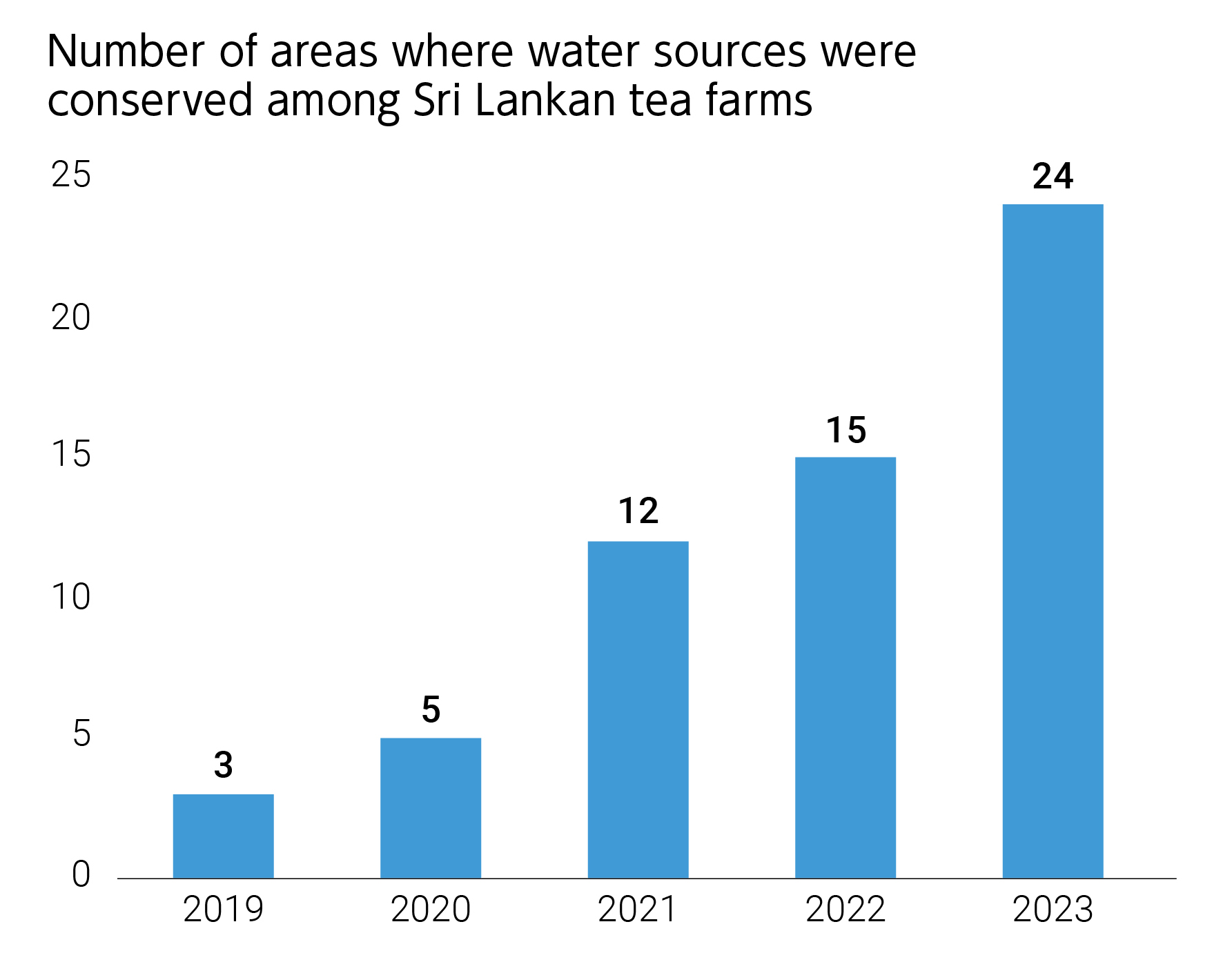

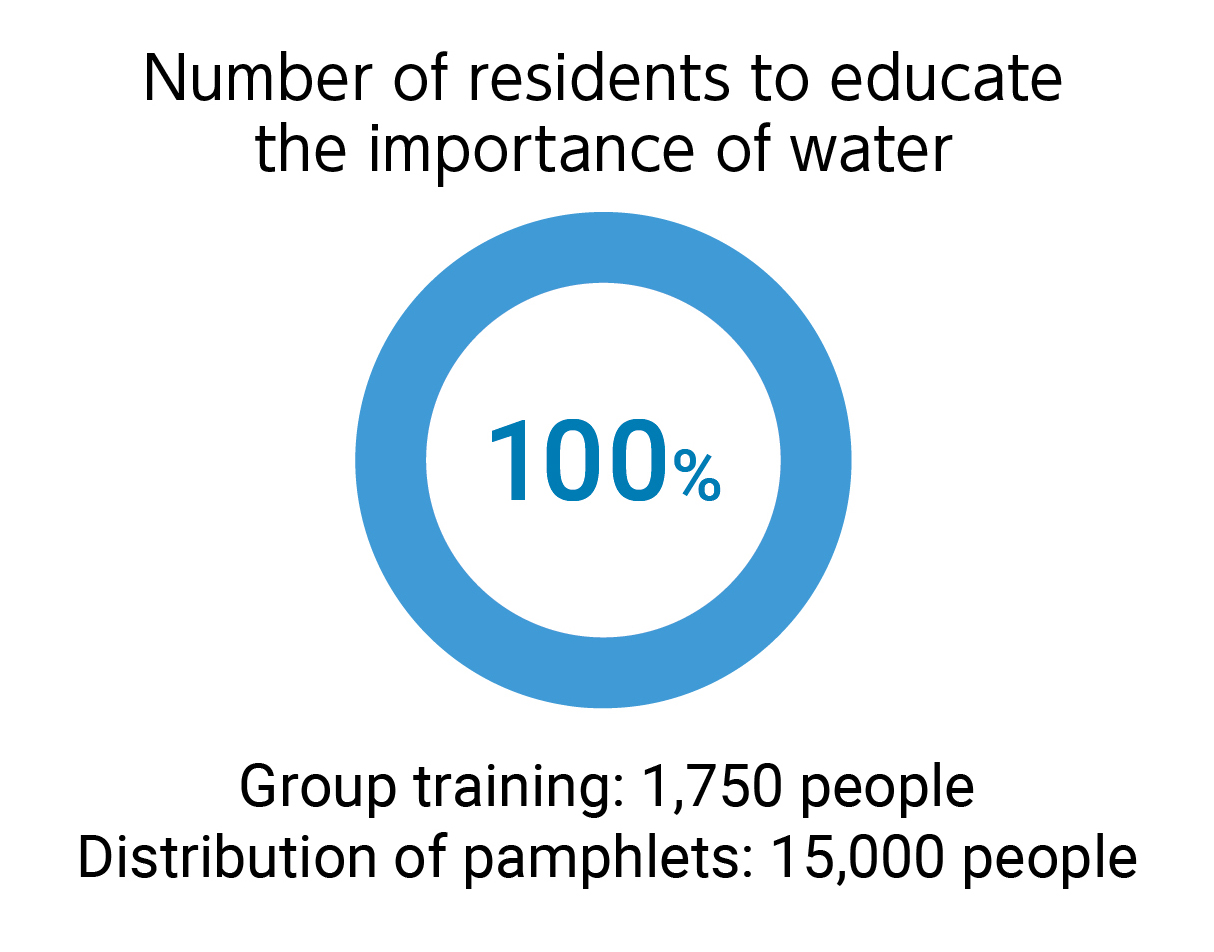

- Conservation of water sources at 24 locations in tea farms in Sri Lanka by the end of 2023. Also, we distributed pamphlets to raise awareness for local residents in water source areas (approximately 15,000 people) , telling the importance of water, water conservation, and protection of basin regions.

- In the Corporate Engagement Program held by the Science Based Targets Network to develop scientific approaches and rules for setting targets related to water resources (since 2021).

- A scenario analysis workshop requested by TNFD at New Belgium Brewing in Fort Collins, Colorado (US), where water stress is extremely high (2023: the details of this workshop were published in beta v0.4 of the TNFD Framework).

- Conserving biodiversity and recharging groundwater through “Water Source Conservation Forest Activities.”

Target

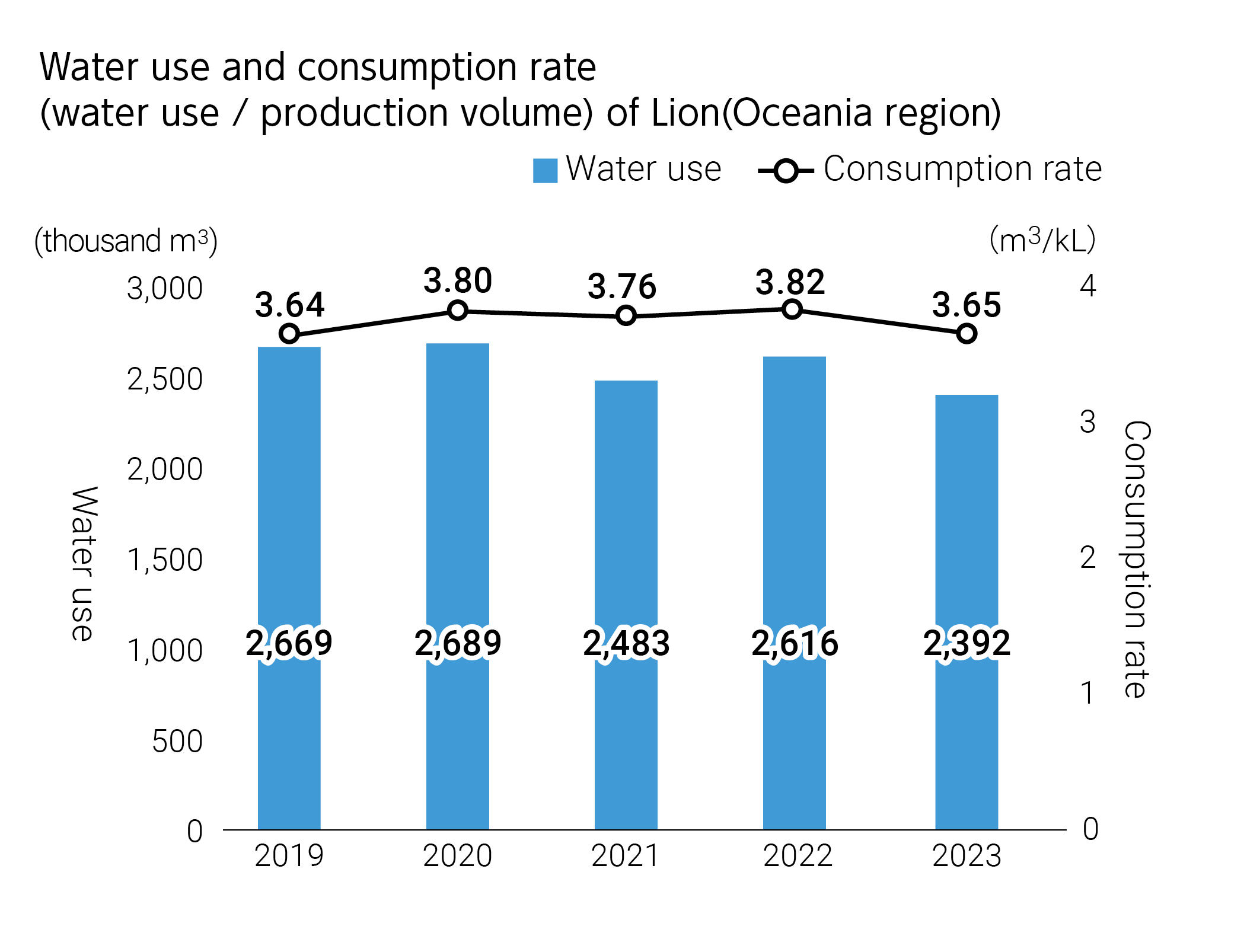

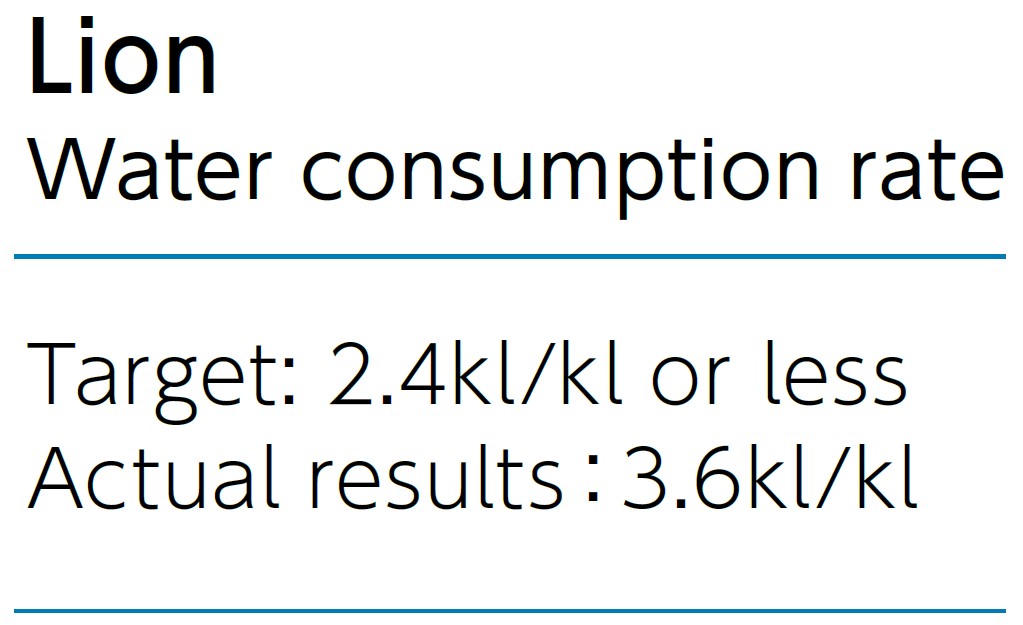

Water consumption rate at production sites and breweries with high levels of water stress (Lion)

2025: Less than 2.4kl/kl (CSV commitment)*1

2025: 2.4kl/kl or less (non-financial target)*2

2024: 3.0kl/kl or less (non-financial target)*2

- *1Tooheys Brewery,Castlemaine Perkins Brewery, James Boag Brewery, Pride

- *2Tooheys Brewery,Castlemaine Perkins Brewery, James Boag Brewery

Progress

Actual results

Conservation activities for water sources on tea farms

In 2018, the Kirin Group began water source conservation activities at Sri Lankan tea farms as a first step in solving water issues in areas where we source our agricultural raw materials. We completed conservation activities at 24 sites by the end of 2023. We educated 1,750 people living near water sources, telling the necessity of conserving water sources. In addition, we have distributed pamphlets to 15,000 residents, aiming to raise awareness of water conservation and watershed protection.

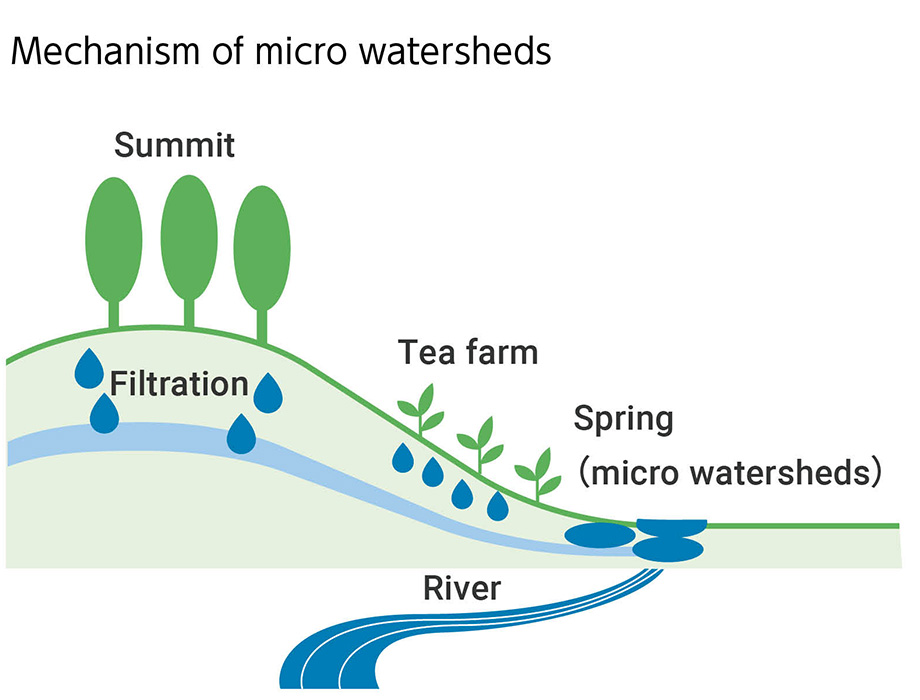

At the tea plantations of the Sri Lankan highlands, tea trees grow on steep slopes. In such places, rainwater penetrates into the ground and gushes out as springs if strata and other geographic conditions are met. These springs are known as micro watersheds, and can be found in the highlands of central Sri Lanka. In almost all cases, these springs are headwaters of rivers that flow through coastal towns. The watersheds are very valuable sources of water for the cities while occupying a tiny area of central Sri Lanka.

As a part of our supports for Sri Lankan tea farms to acquire Rainforest Alliance certification, we collaborate with farm managers each year. Through discussions with the managers that conservation activities of watersheds were being held up due to lack of funding although the Sri Lankan government recognized importance of micro watersheds and was willing to conserve them. Therefore, in 2018, Kirin Holdings and the Rainforest Alliance started working on activities to conserve watersheds at the farms, now collaborating with Plantation Human Development Trust (PHDT) and Estate Worker Housing Cooperative Societies (EWHCS), affiliated organizations of the Sri Lankan government.

During our most recent visit (March 2024) to farms, we saw progress in conservation efforts, with micro watersheds on farms being fenced off to prevent animal access and inappropriate use of water by others. We are commenced planting native plant species as a natural buffer around the watershed. We expect that the species will provide a diversity of vegetation at tea farms, which currently have a single crop, and prevent soil of mountain slope from flowing down to water sources as a result of torrential rain.

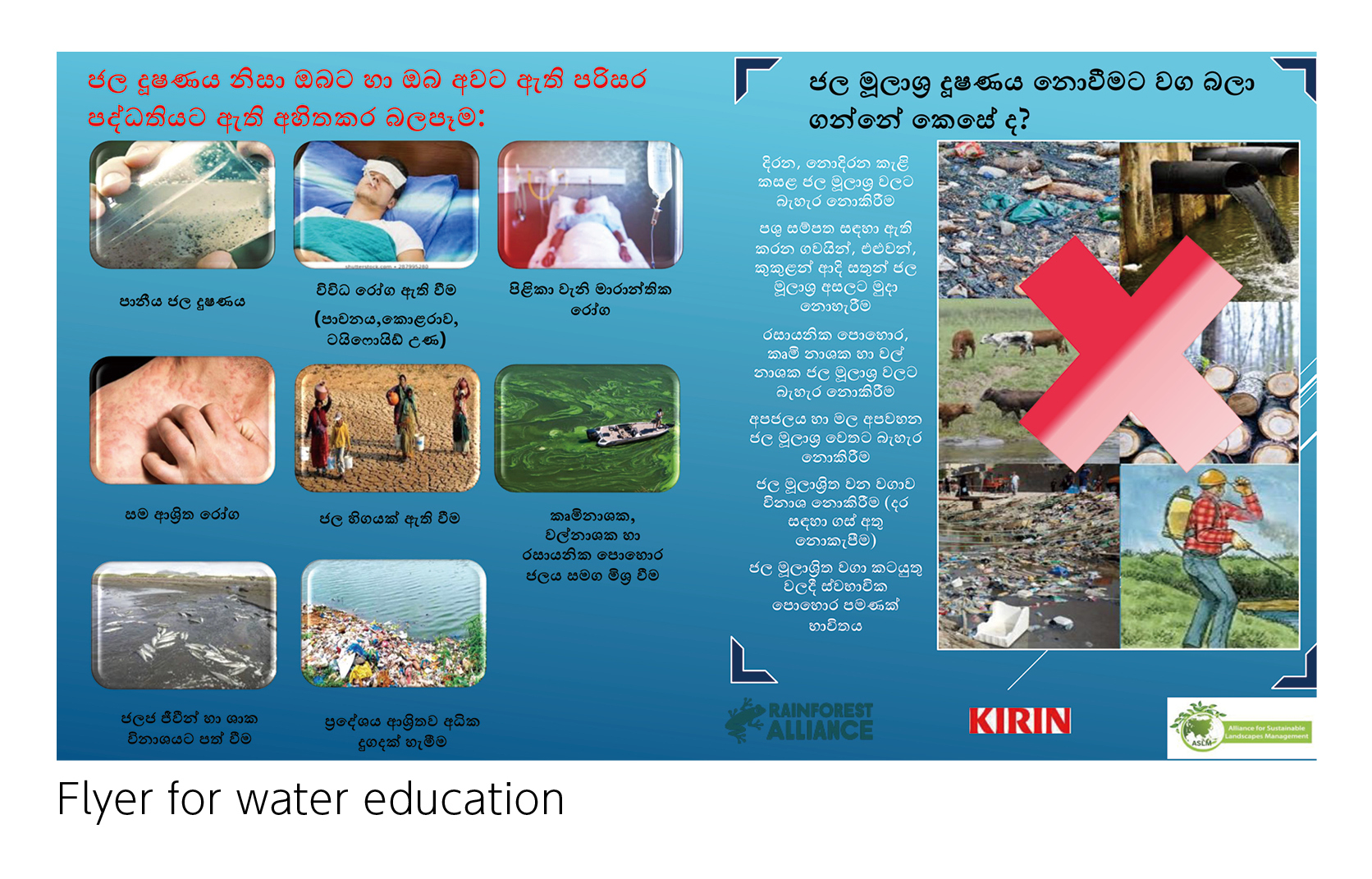

Education programs to teach the value of water

The Kirin Group is conducting an education program to teach residents living near water sources about the importance of water and the functions of micro watersheds. At some farms, we are also working to incorporate our educational programs as a part of curriculums of nurseries for children of tea pluckers and elementary schools. We have provided the program to 15,000 people, our initial target, and plan to expand the program further.

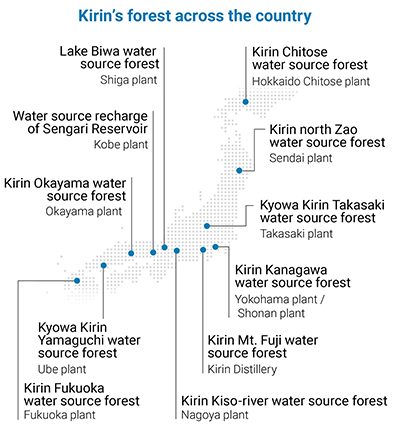

Water Source Forest Conservation Activities

“Water Source Forest Conservation Activities”, an activity to protect water source forests at our plants, began in 1999 with the industry's first forest in the Tanzawa area of Kanagawa Prefecture, which is the source of water for the Kirin Brewery Yokohama Plant, and continues today at 11 locations throughout Japan. Based on medium- and long-term agreements with local governments and related organizations that manage water source forests, we have planted trees, cleared undergrowth and branches, and thinned trees, and many of our forests are now bright and lush. In some locations, customers are invited to participate in these activities.

Grassland conservation activities to recharge groundwater

Yatsushiro Plant, one of production sites of Mercian, sent its three employees to “Aso Grassland Restoration Project” which aims to make Aso district a World Heritage Site. The project supports controlled open burning of grassland, a traditional methodology to maintain quality of grasslands. The methodology enables Aso district, where Yatsushiro Plant sources its water, to secure abundant groundwater. Maintaining grasslands not only nurtures groundwater, but also protects habitats for a wide variety of flora and fauna, including endangered species.

Production

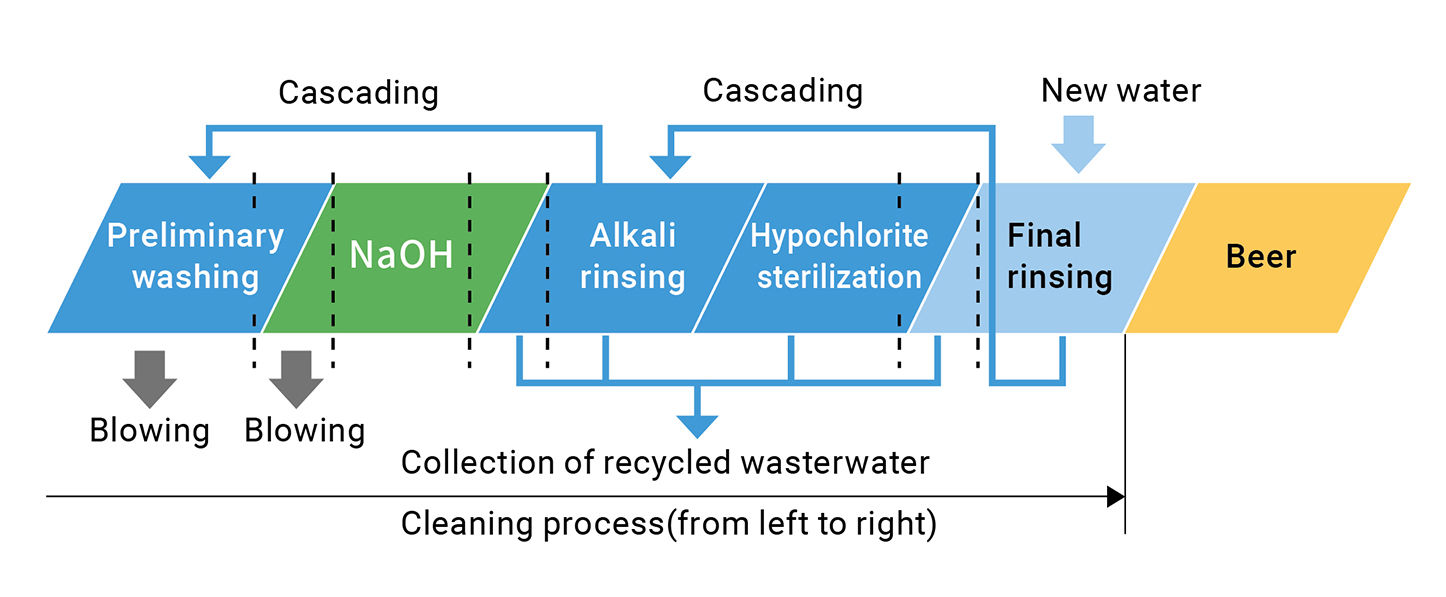

In our production process, we use a lot of water in cleaning and sterilizing processes. We have established management system to strictly control quality of the cleaning processes and water consumption by optimizing flow rate and other parameters. We also actively promote reuse of water, considering characteristics of processes.

For example, the rinsing water that we use in the final cleaning step of a equipment is relatively clean, so we can use it again for the initial cleaning step of other equipment. In this way, the water used for cleaning is cascaded for repeated use according to water quality. In order to ensure that equipments are appropriately cleaned, it is necessary to know how to use the equipment, such as how to balance the amount of water that can be recovered with the amount of water that is used, and how to time the process. The Kirin Group is achieving a high level of water conservation by accumulating best practices and sharing them among production sites.

In 2009, Lion partnered with the government of Queensland, Australia, where water stress is extremely high, to install a reverse osmosis (RO) filter at the Castlemaine Perkins Brewery, to minimize water use in brewery. Lion introduced this filter in order to reduce 50% of fresh water usage in the brewery by recycling wastewater. The brewery uses treated water by RO in non-product related processes, such as cleaning, cooling, and pasteurizing. Lion is leading sustainable water use in Kirin Group.

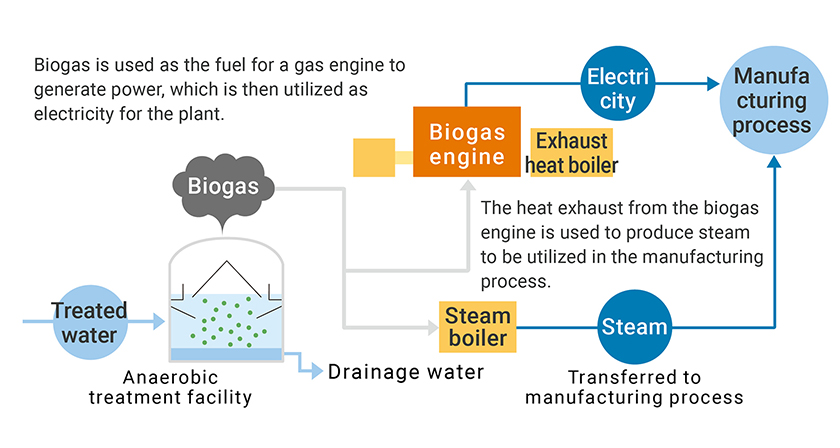

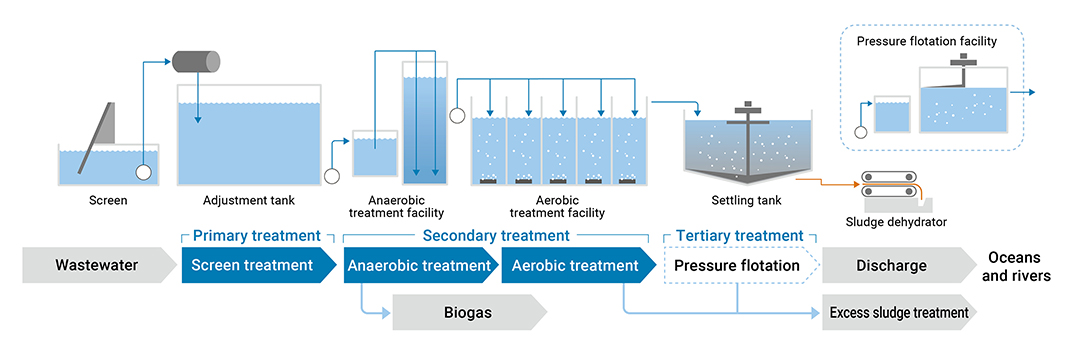

Wastewater and the usage of biogas

Kirin Group sets higher quality standards of waste water treatments than those required by regulations. Breweries and plants in basin areas with strict regulations remove phosphorus and solids by pressure flotation in addition to conventional waste water system. We process excess sludge generated from aerobic treatment and pressure flotation into fertilizer and soil conditioner.The Kirin Group discharges clean water into the ocean, rivers, and sewers, considering local aquatic ecosystems. In our breweries, we have introduced anaerobic treatment system to purify the wastewater generated by production processes.Anaerobic treatment does not require electricity for aeration, and anaerobic microorganisms generate biogas as a by-product of the treatment process. The biogas contains methane as its main component, and it can be utilized in biogas boilers and cogeneration systems. The origin of biogas is agricultural products such as malt which is grown by absorbing CO2 from the atmosphere by photosynthesis. Thus, the gas is classified as a renewable energy source since the amount of CO2 generated from its combustion does not affect global CO2 volume.

Environmental protection activities in basin regions

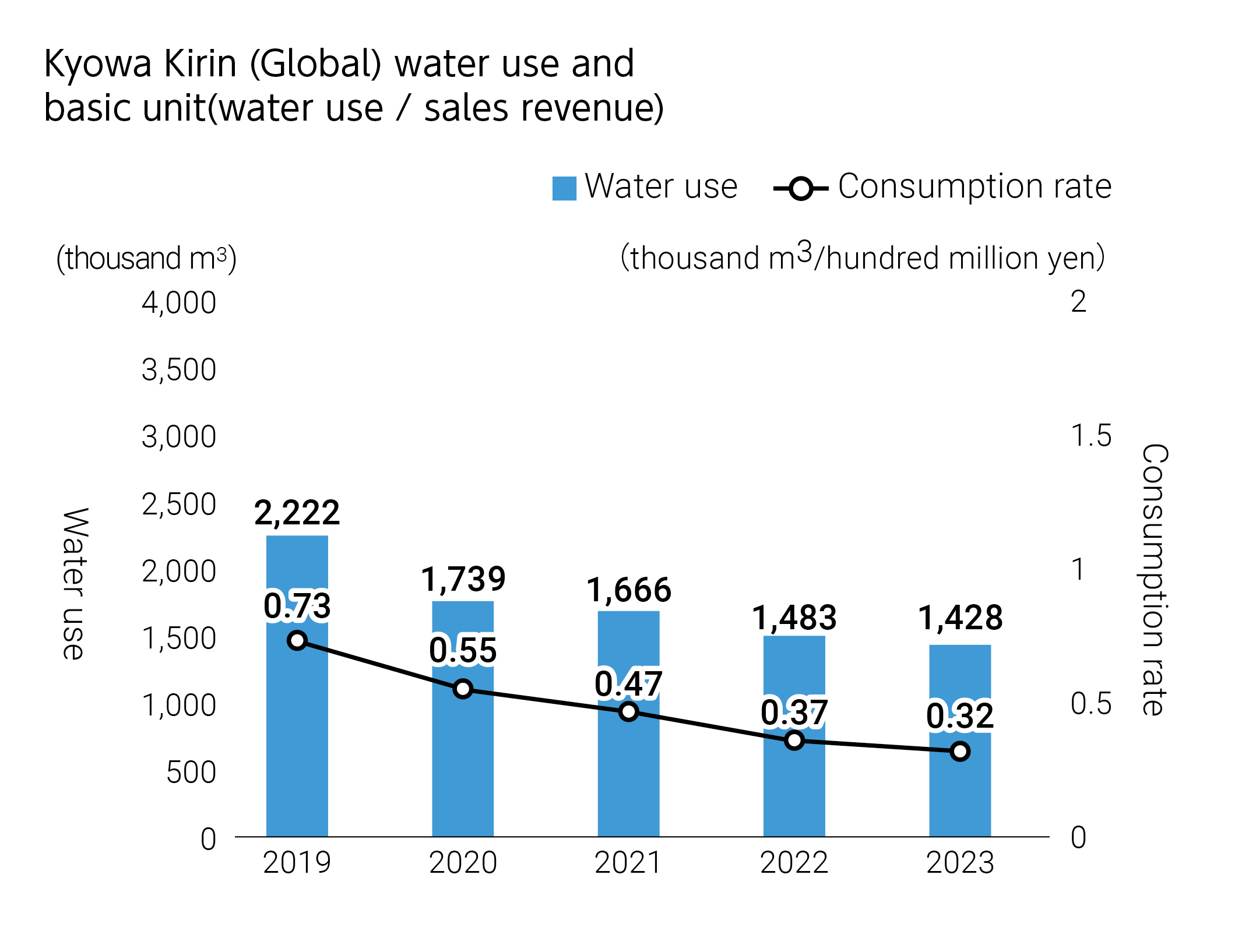

At the various production plants of the Kirin Group, we are conducting a range of environmental protection activities, particularly riverside clean-up activities in cooperation with local governments and NGOs. At our breweries and plants, including those of Kirin Brewery, Kirin Beverage, Mercian, Kyowa Kirin, and Koiwai Dairy Products, we engage with local environmental activities, focusing on rivers where we intake water for production and other nearby rivers.

At Yamaguchi Production Center of Kyowa Hakko Bio, employees conduct clean-up activities in the waters off Hyakken, a port facility where chemicals and glucose solutions are unloaded.

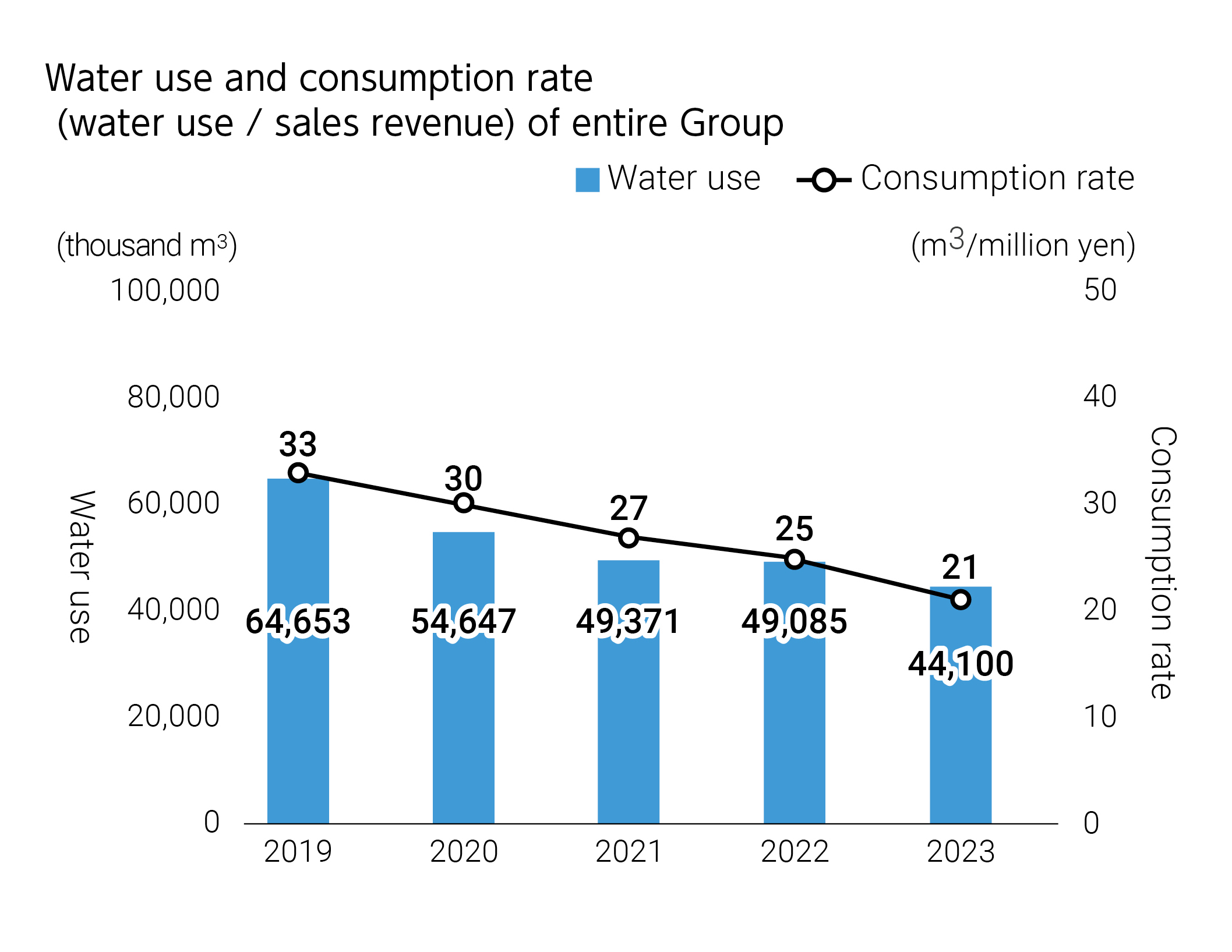

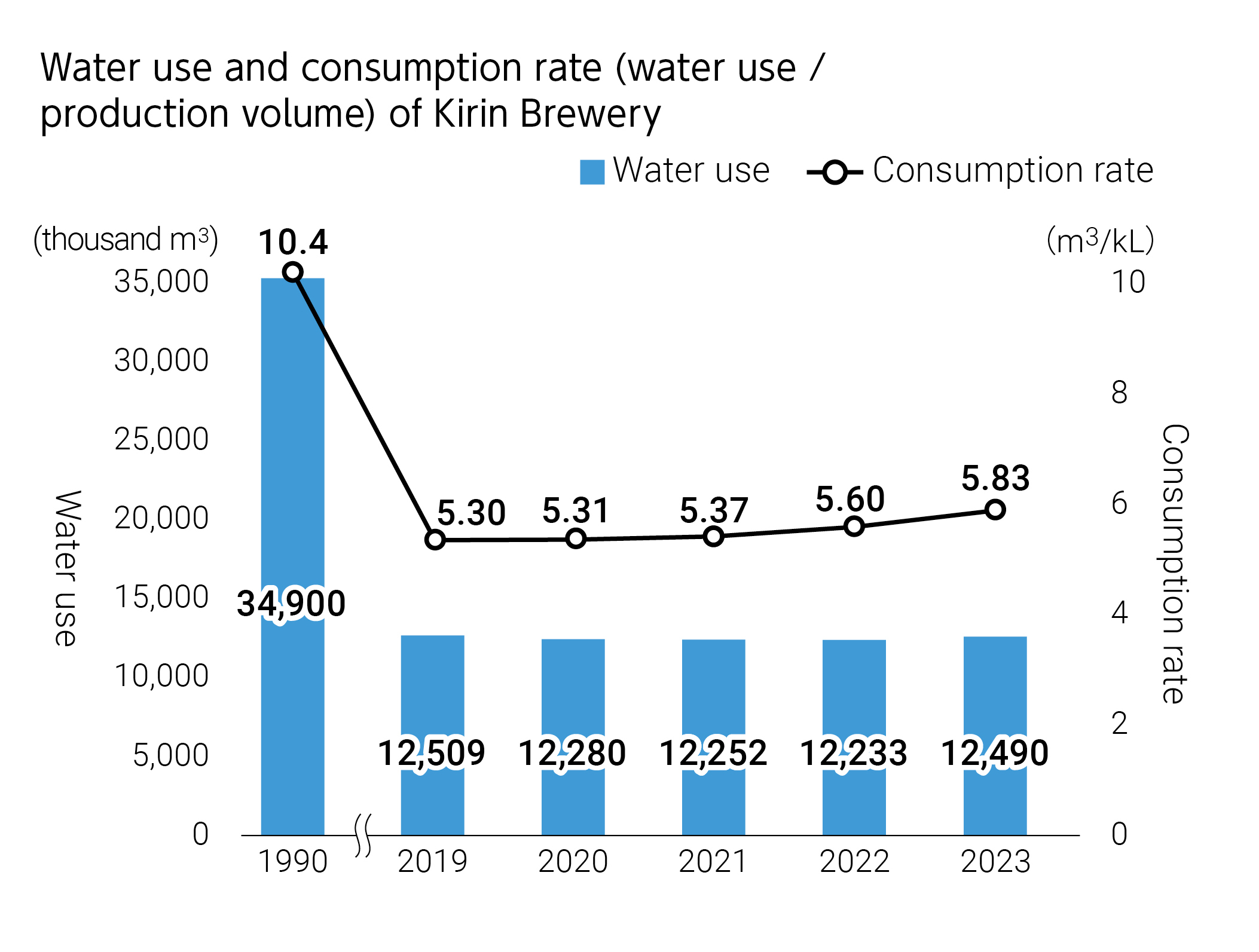

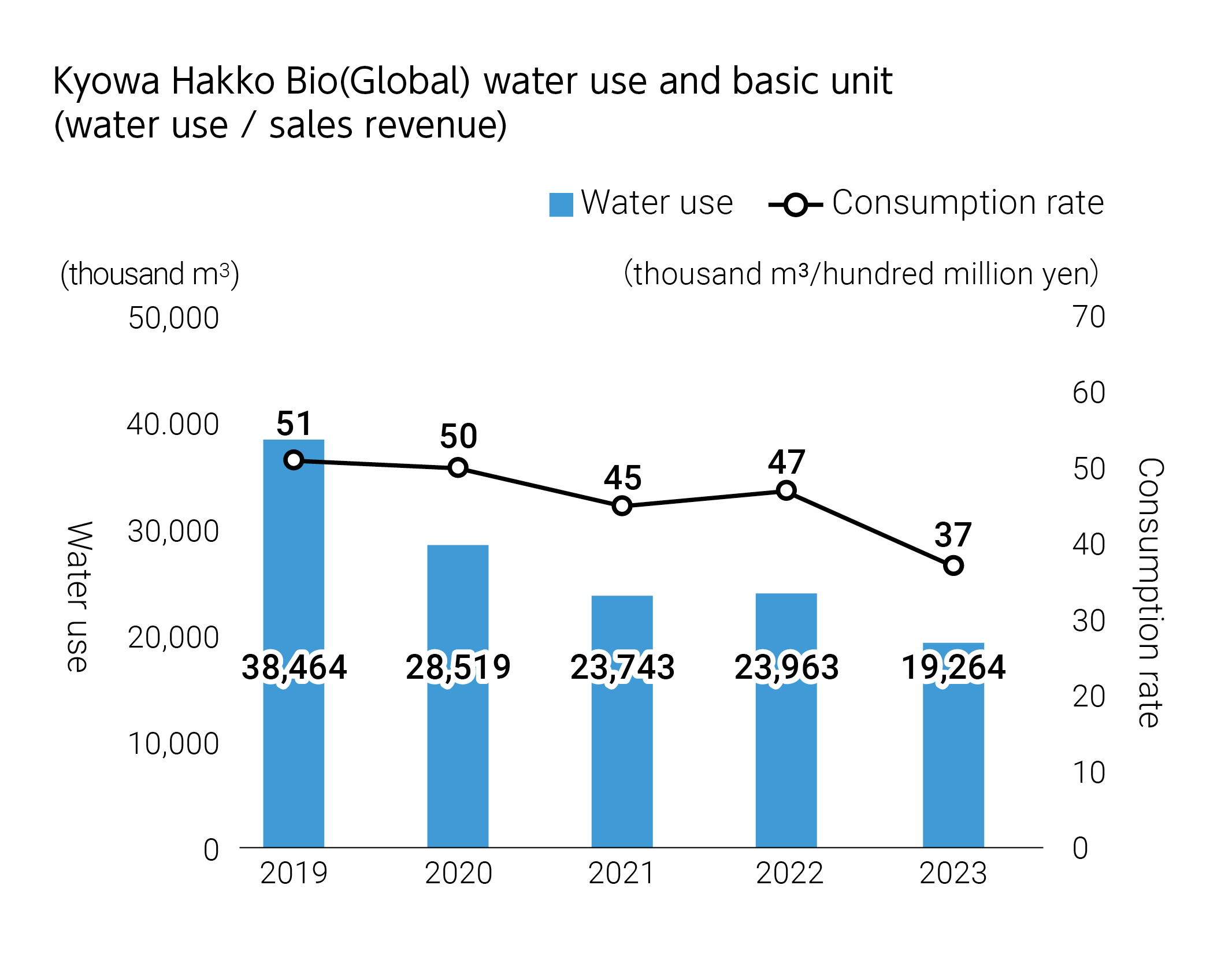

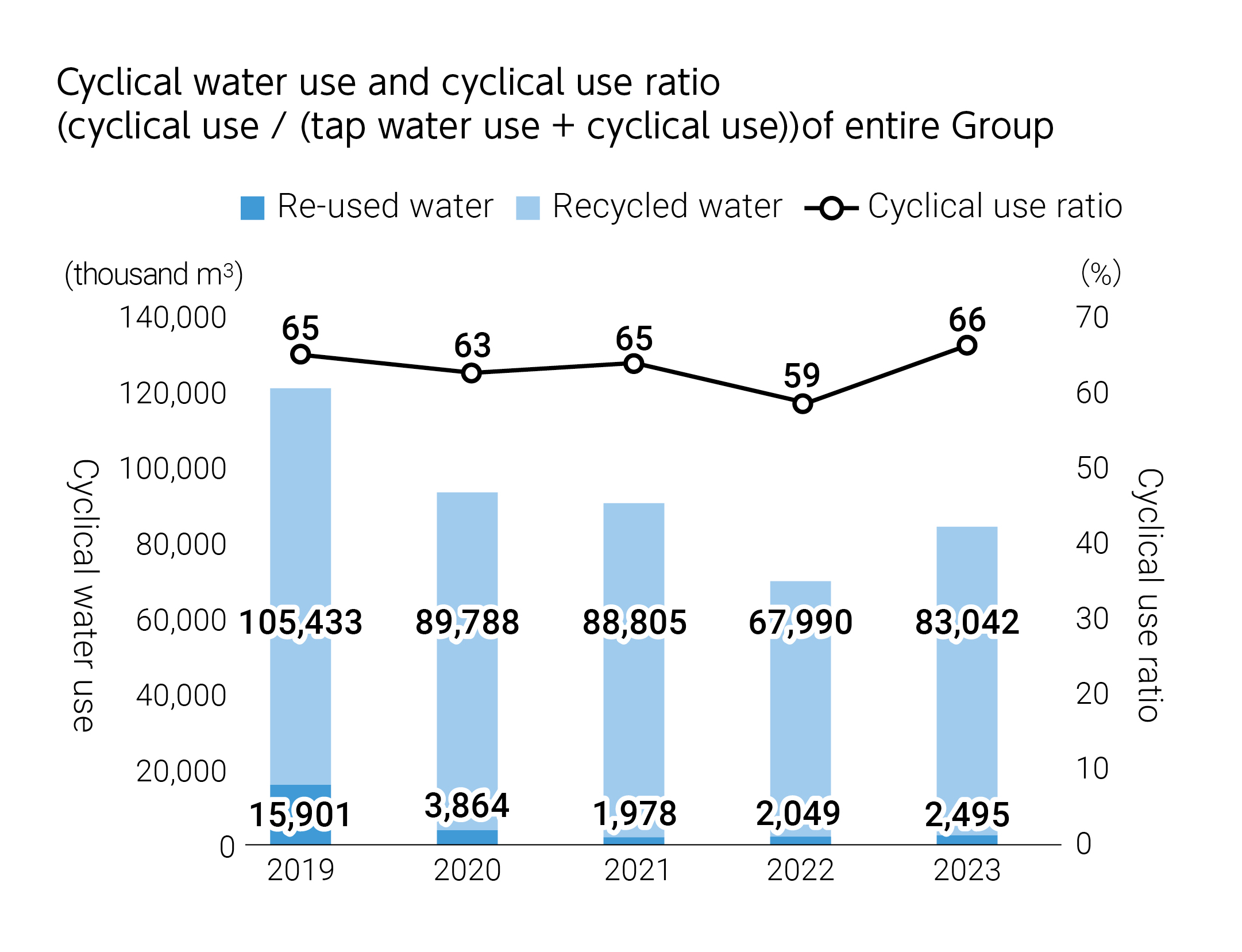

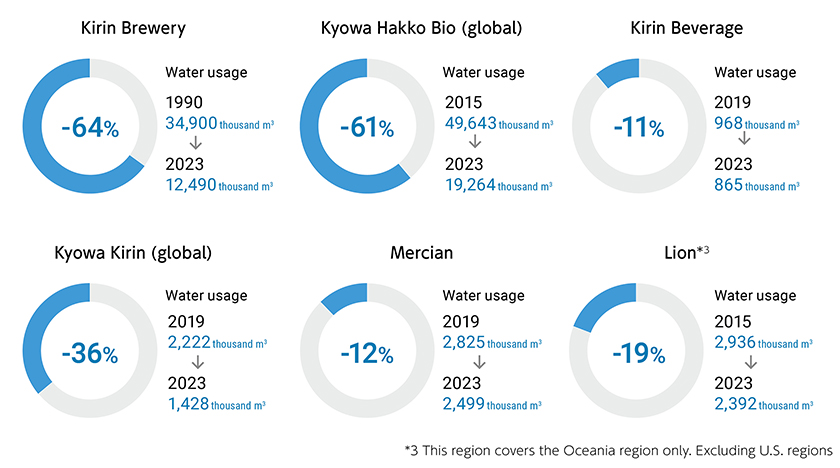

Key data related to water resources