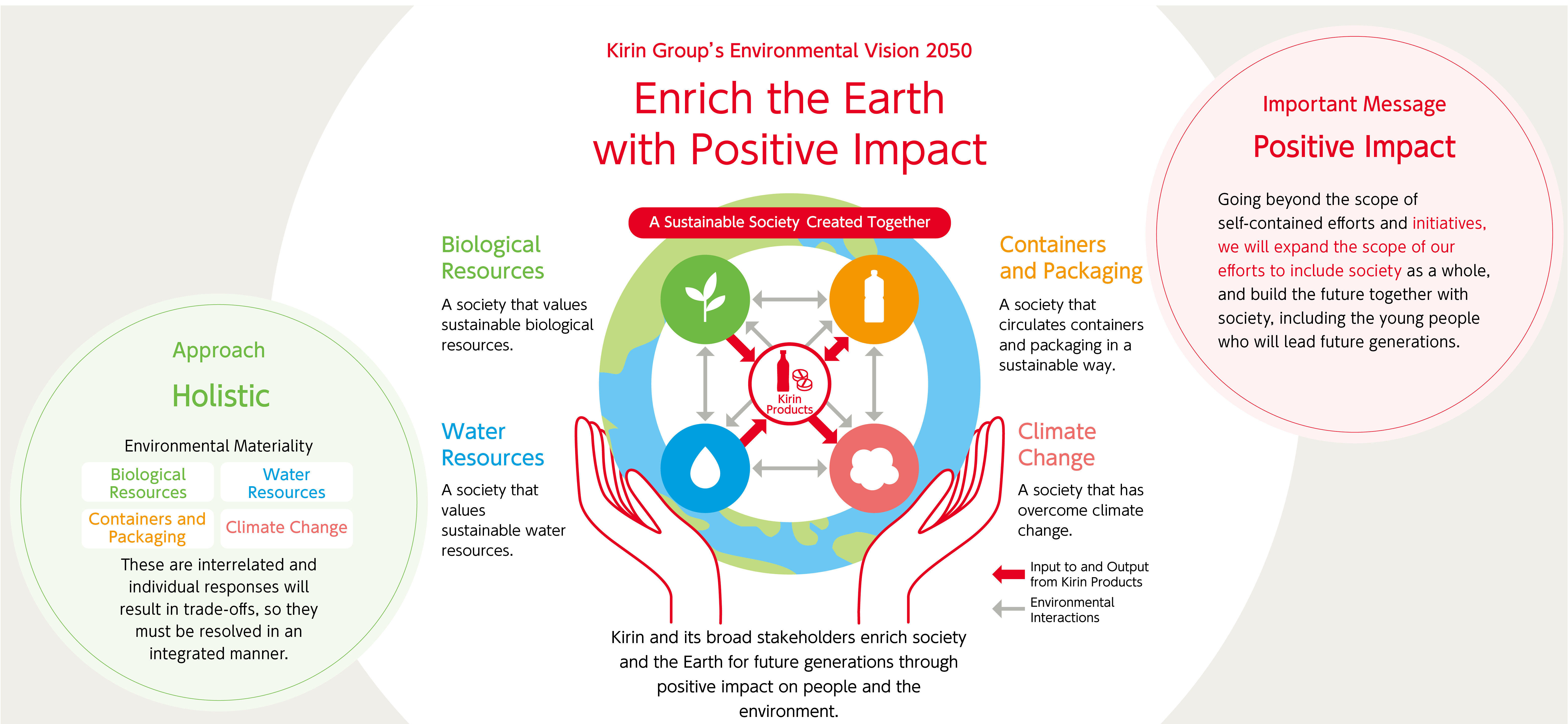

Kirin Group's Environmental Vision 2050

Enrich the Earth with Positive Impact

Society has reached a major turning point against the backdrop ofgrowing global environmental problems, including the climate crisis,the ongoing loss of biodiversity, and plastic pollution of the oceans.Industries such as the Kirin Group, which rely on natural bounty suchas water and agricultural products, are susceptible to environmentalproblems and there is need to address such issues urgently.

Through scenario analysis based on the TCFD recommendations,which has been conducted since 2017, the Kirin Group has graspedthe seriousness of the impact that climate change have on agriculturalproducts and water resources. We have learned that in order topass on a sustainable Earth to future generations, it is not enough tosimply minimize negative impacts and achieve neutrality. Furthermore,corporate environmental policies are expected to evolve from beingself-contained within a company to having a positive impact onsociety as a whole.

In order to respond to such societal demands, the Kirin Group has further developed the idea of an "integrated" approach thatholistically addresses complex and interrelated environmental issues(biological resources, water resources, containers and packaging, andclimate change) into our revised "Kirin Group's Environmental Vision2050" and "Positive Impact" approach, which were discussed andresolved by the Board in 2020.

Under this new Vision, together with the young people who will lead the future, we will create a prosperous world for the next generation.

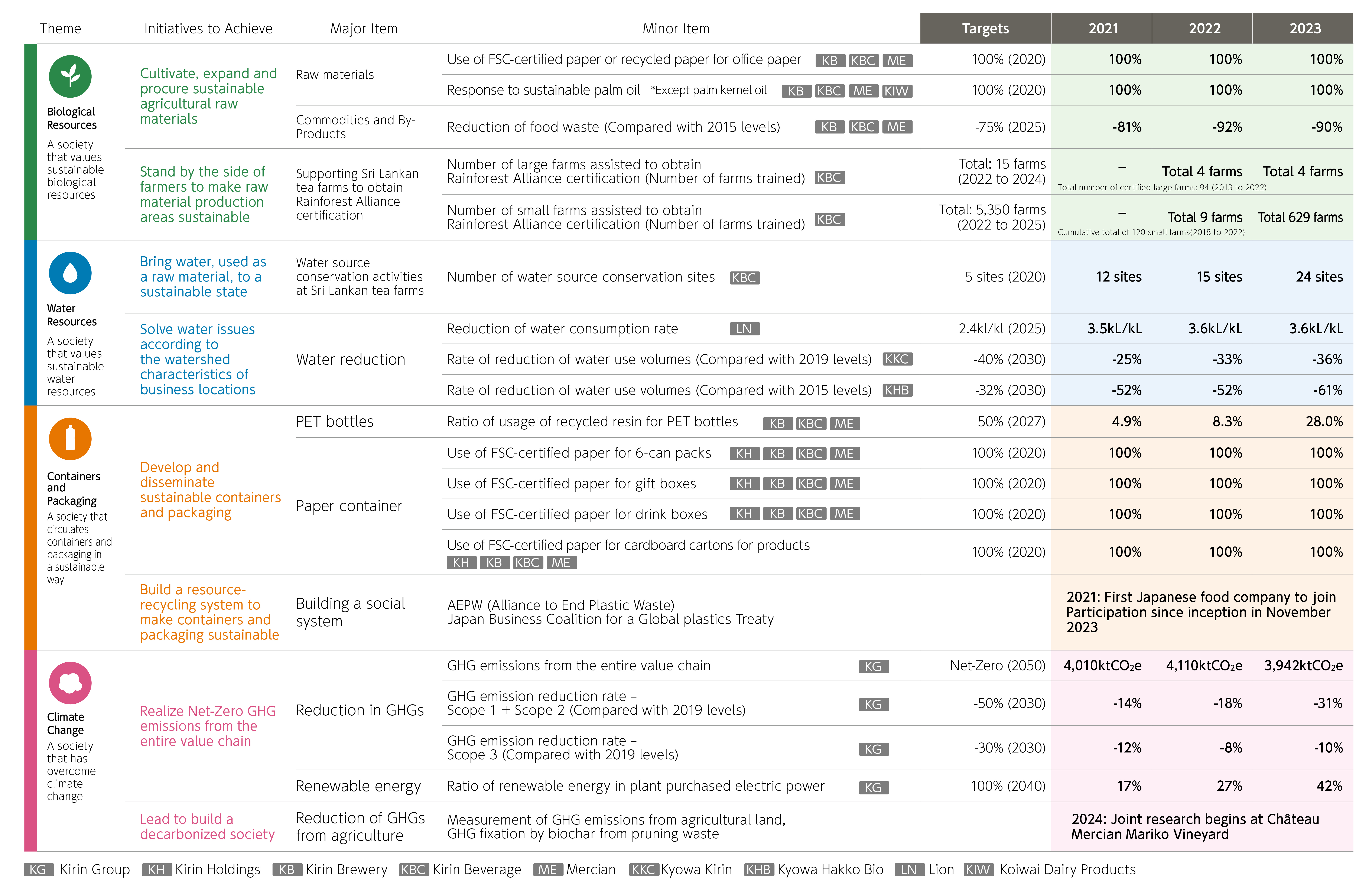

Progress (2023)

Part of the "Initiatives to Achieve" of the Environmental Vision isreflected in the "CSV Commitment", a medium- to long-term actionplan that each business is working on to achieve the "CSV Purpose".The status of their implementation is monitored on a quarterlybasis and reported to the Kirin Holdings Board of Directors. Currentprogress, including qualitative elements, is as follows.