Overcoming climate change

Overcoming climate change

The Kirin Group was one of two companies that represented Japan when we presented our environmental measures to the world at the third session of the Conference of the Parties to the United Nations Framework Convention on Climate Change in Kyoto in 1997. The Kirin Group has long been working to reduce GHG emissions. We have achieved significant reductions, having set an ambitious target of “reducing GHG emissions across the entire value chain by half from the 1990 level by 2050” in 2009. Since the adoption of the Paris Agreement in 2015, we have been leading the way in creating a decarbonized society, having gained a renewed understanding of our impact on natural capital such as agricultural raw materials and water through scenario analysis based on the TCFD recommendations, set science-based targets for the reduction of greenhouse gas emissions, and declared our aim to switch to 100% renewable energy for electric power used by 2040 and achieve net zero GHG emissions by 2050.

Main Activities

- Our long-term target to achieve net zero GHG emissions across the entire value chain by 2050 received certification as the science-based net zero target (July 2022: the first in the global food industry)

- Obtained approval for the science-based 1.5℃ target (2020)

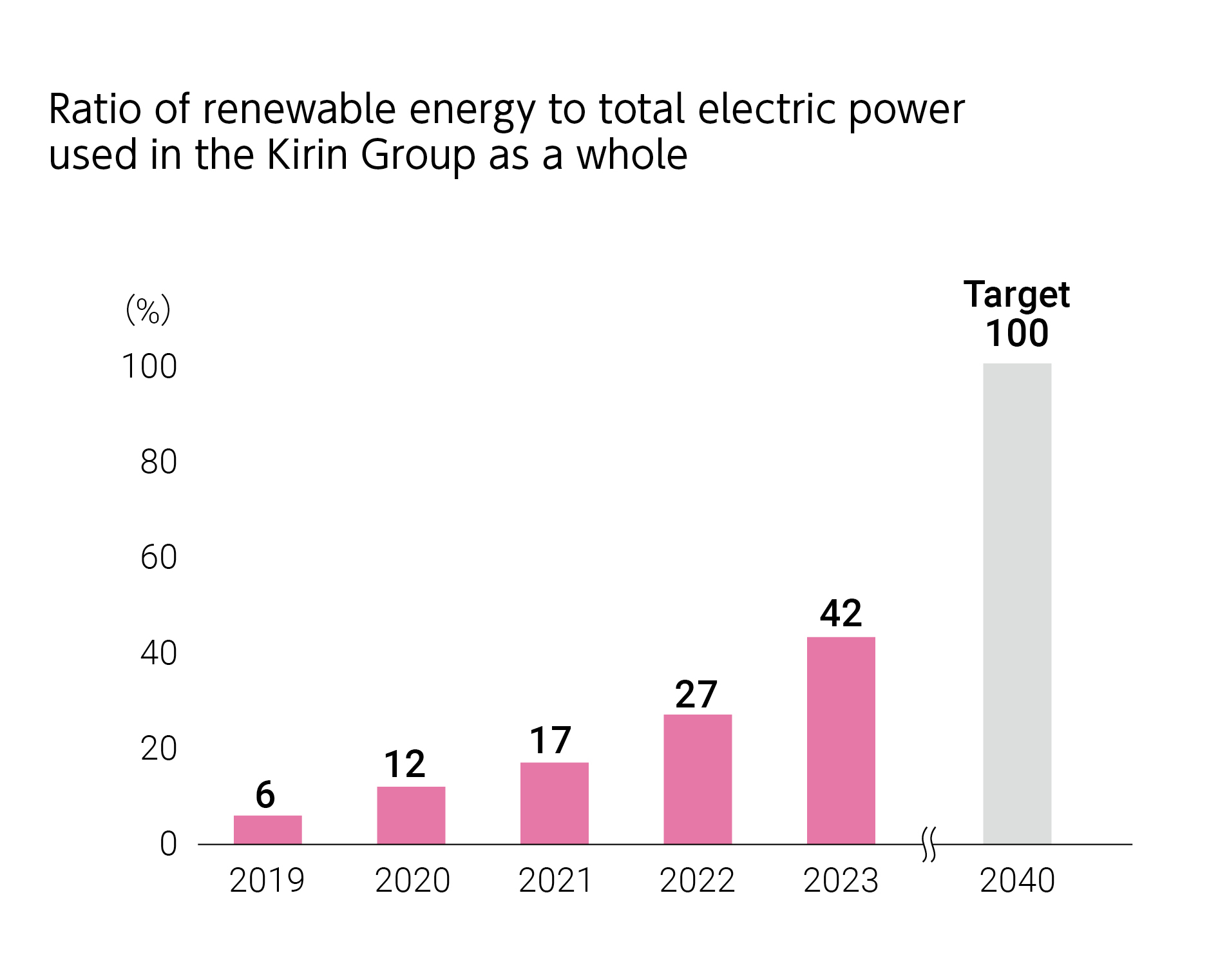

- Joined RE100 and set a target for the proportion of renewable energy in electric power used (100% by 2040) (2020)

- Achieved 100% renewable energy in purchased electric power at all Kirin Brewery plants (two in 2022, three in 2023, and four in 2024) and all business offices (in 2024), Kyowa Kirin Takasaki Plant, Ube Plant, research laboratories, etc., and the Lion's plants in Australia and New Zealand (2023)

- Introduced large-scale solar power generation facilities at nine Kirin Brewery plants (through 2023, including eight breweries and plants with PPA model purchasing), Mercian Fujisawa Plant (2023), Kyowa Kirin Ube Plant (2023), and Lion Castlemaine Perkins (2019)

Targets and Progress

Reduction in GHG emissions

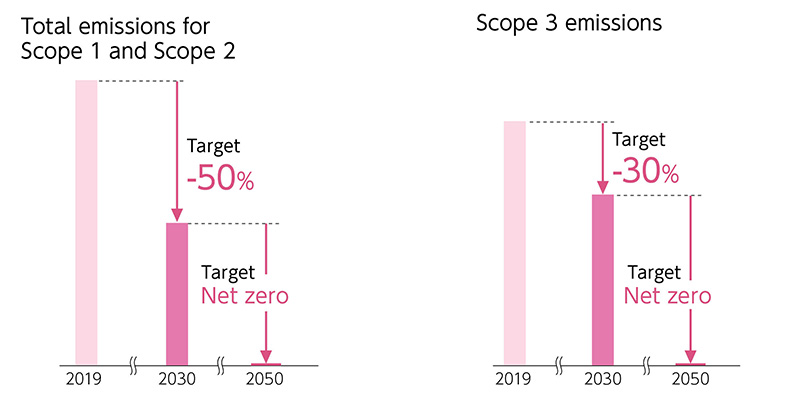

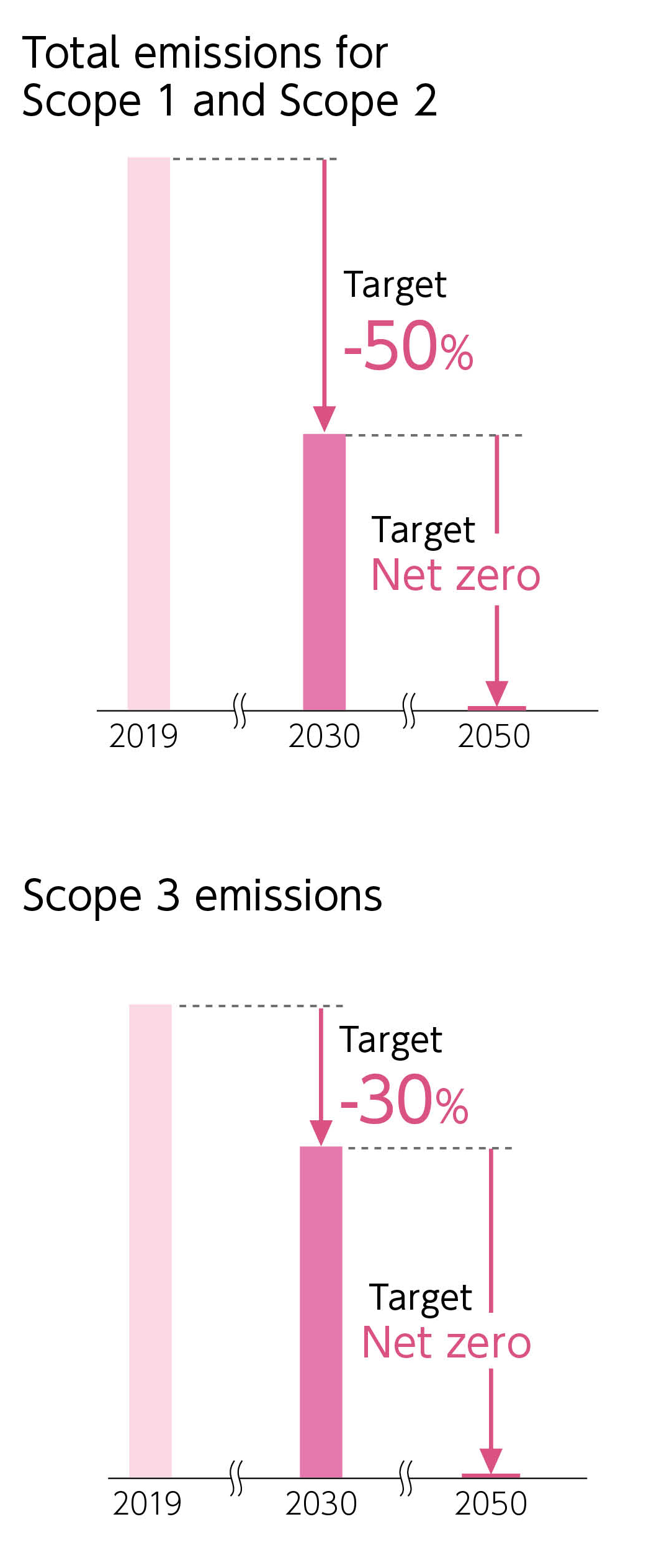

2050 Net zero (Environment Vision 2050)

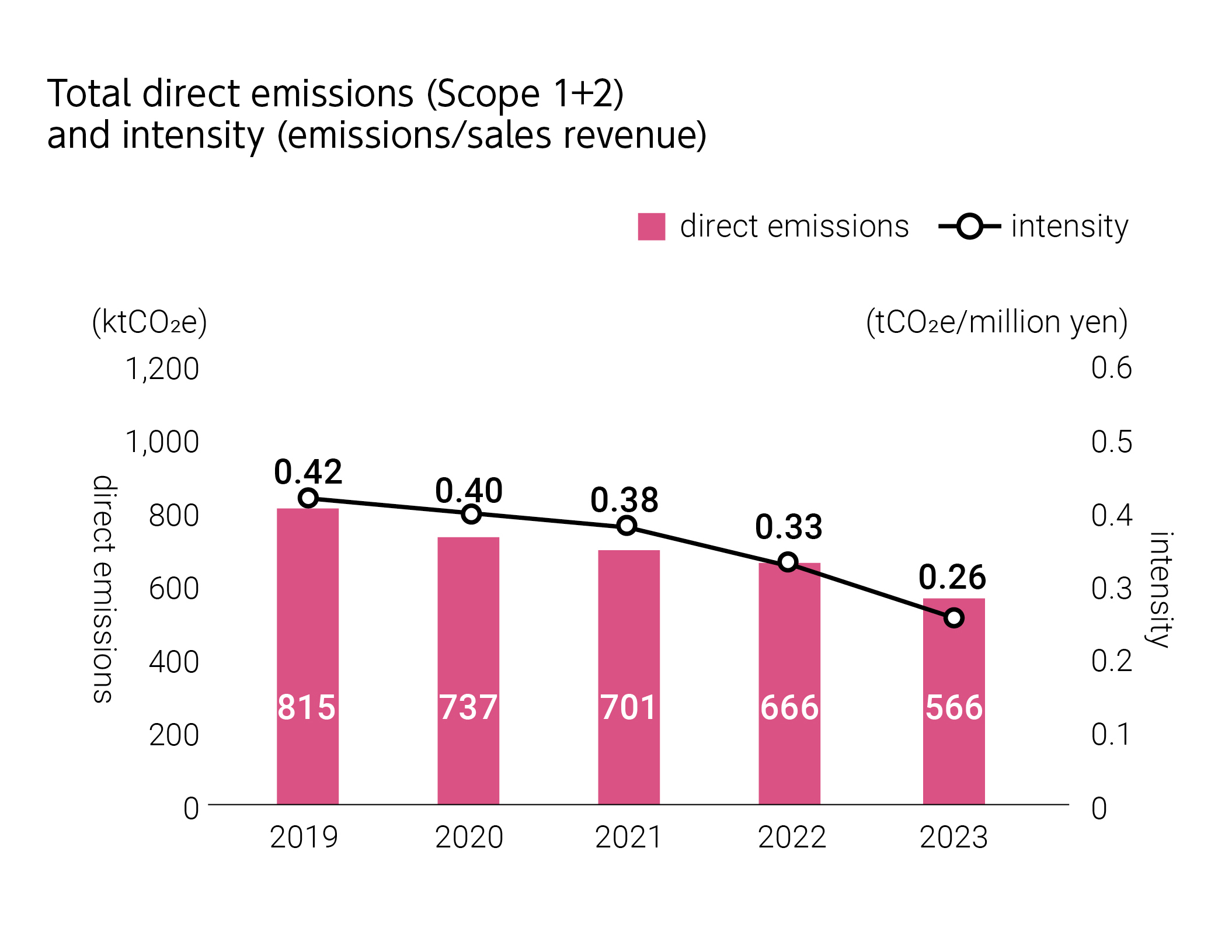

2030 Scope 1 + 2 down 50% and Scope 3 down 30%

(compared with 2019) (SBT for 1.5℃ target)

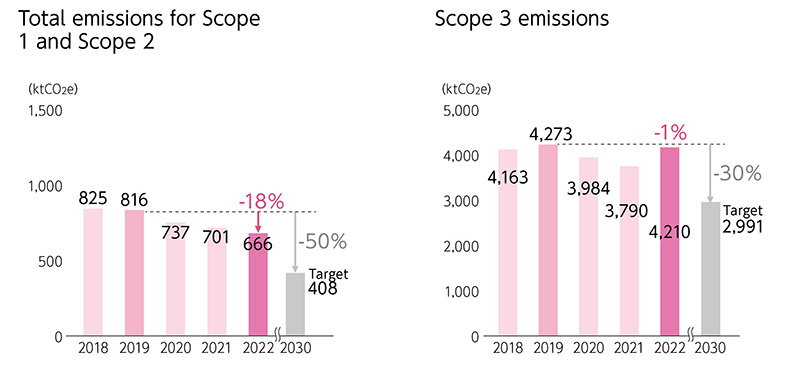

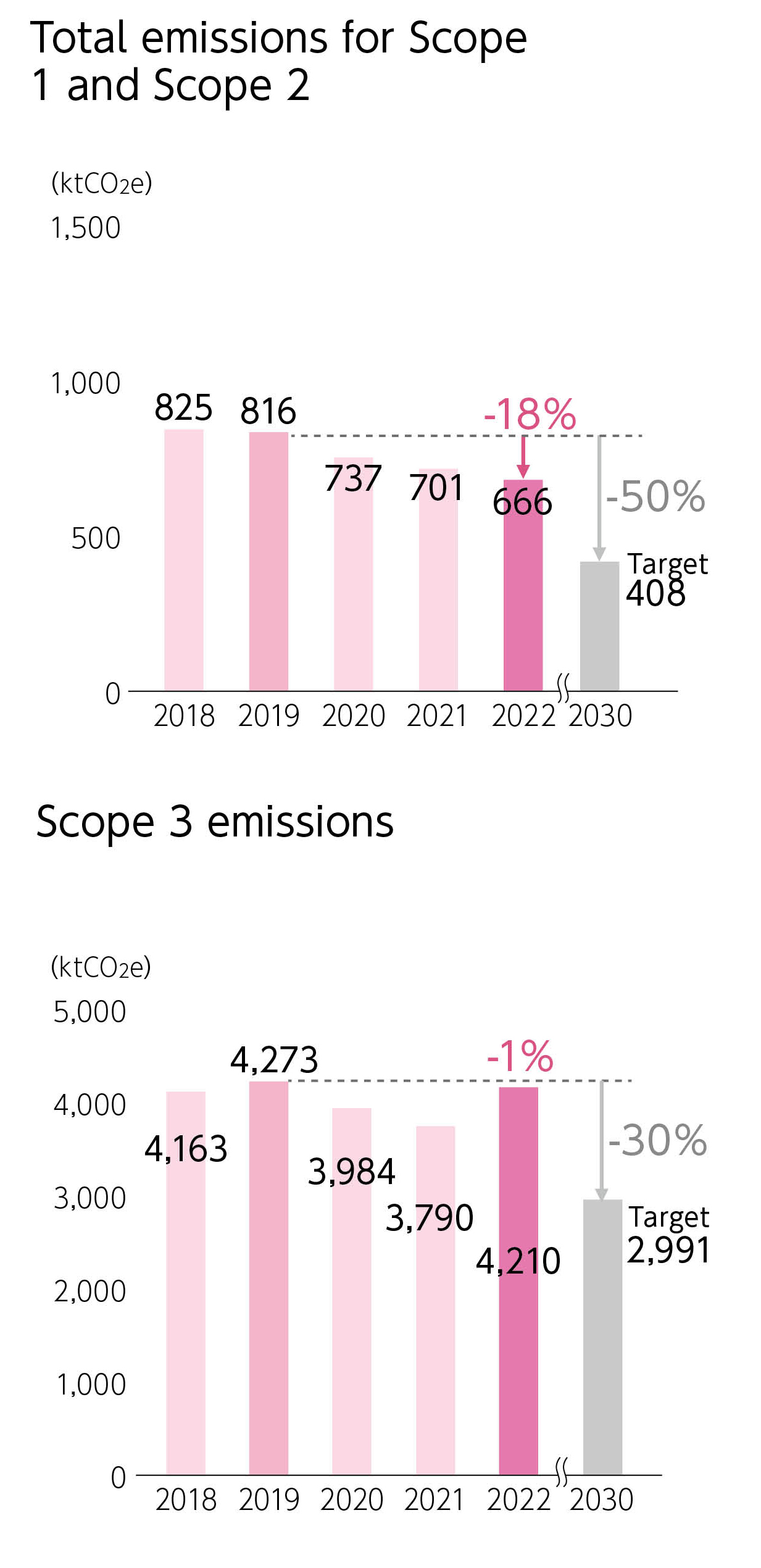

2024 Scope 1 + 2 down 23% (compared with 2019) (non-financial target)

Actual results

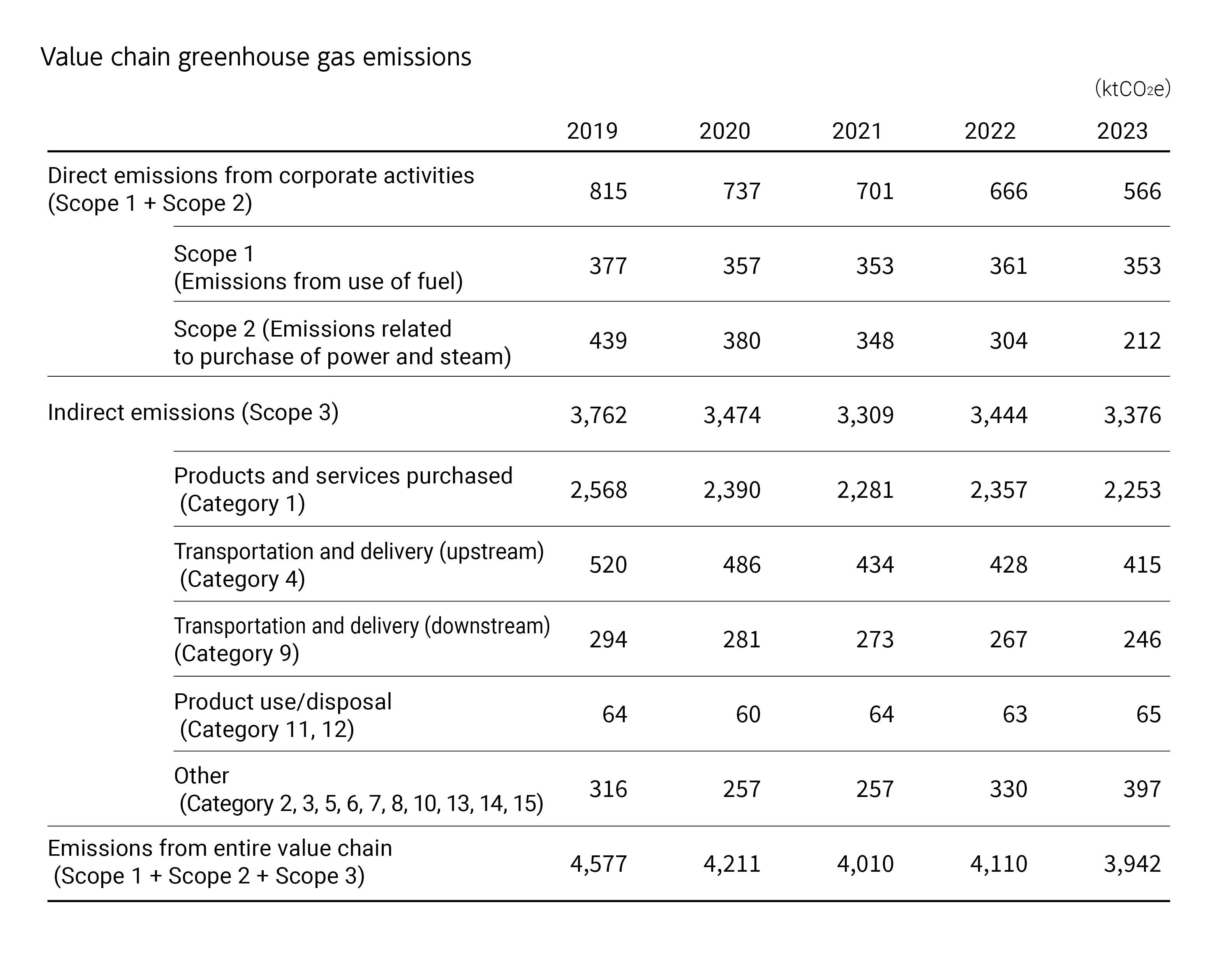

- In December 2020, we upgraded our previous “SBT for 2℃” target, and received approval for our “SBT for 1.5℃” target.

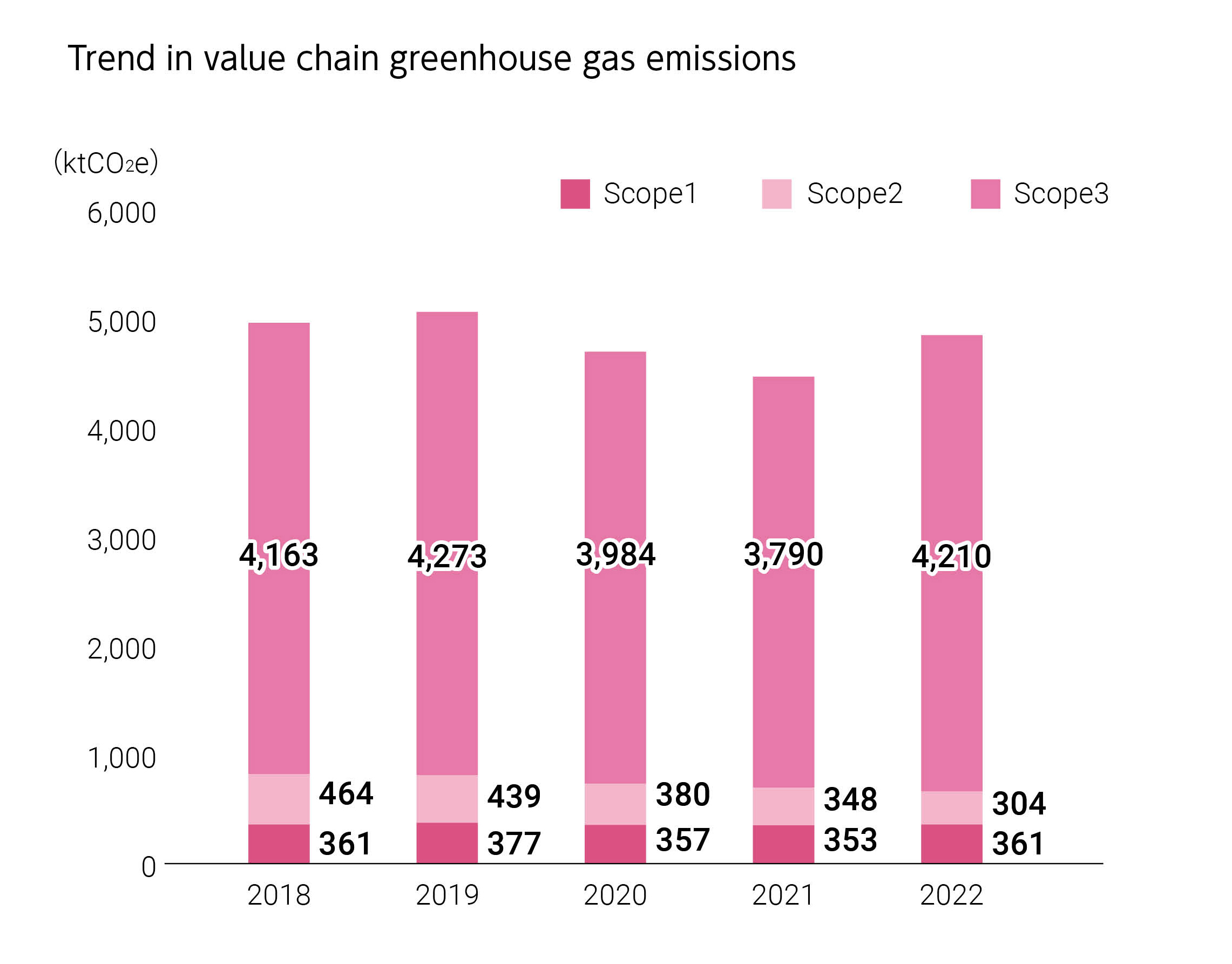

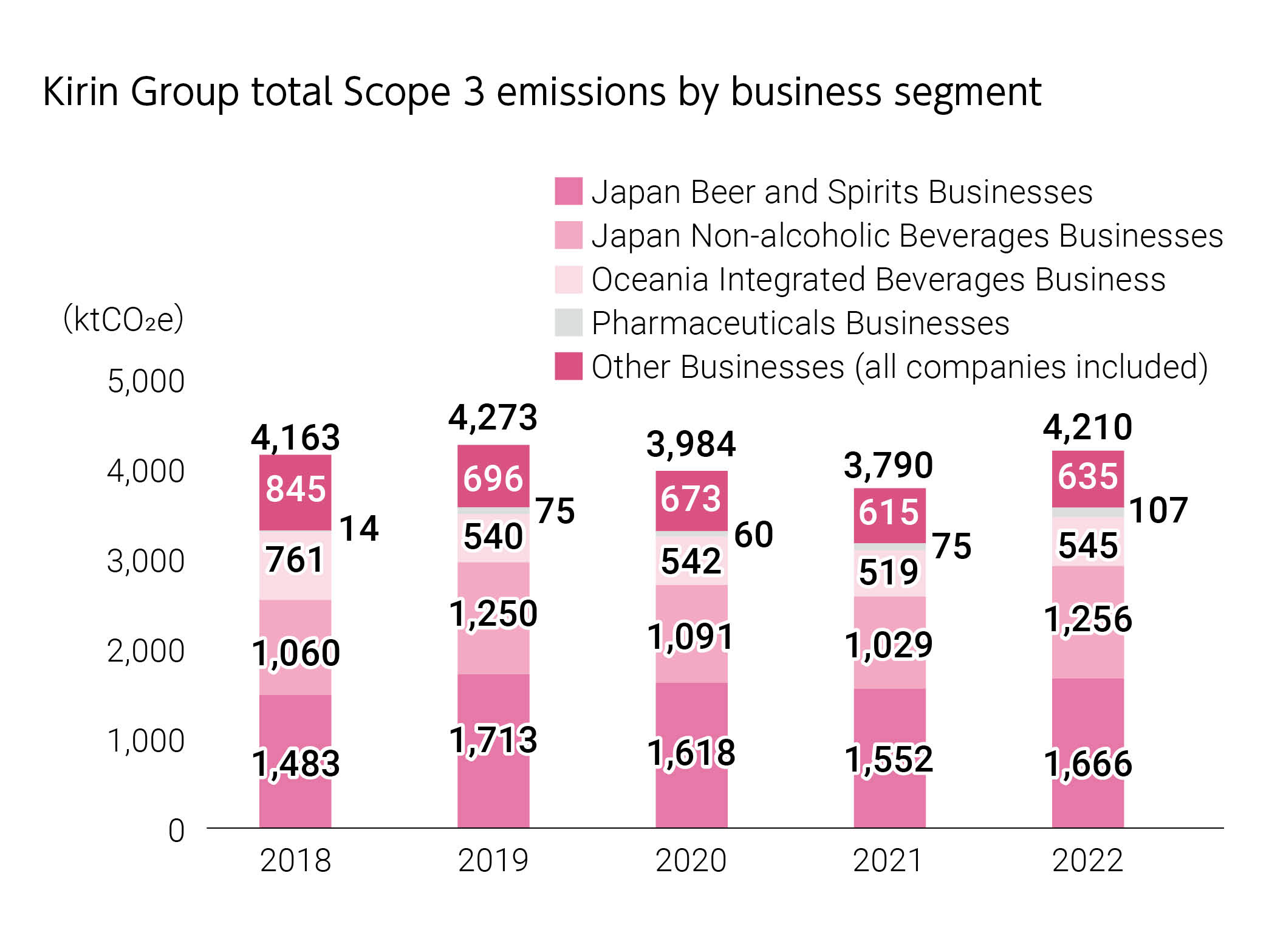

- Since 2019, we have excluded Lionʼs non-alcoholic beverages business from Scope 3 emissions, and we have changed to the LCA database (IDEA) offered by the National Institute of Advanced Industrial Science and Technology (AIST) for emissions per unit of product

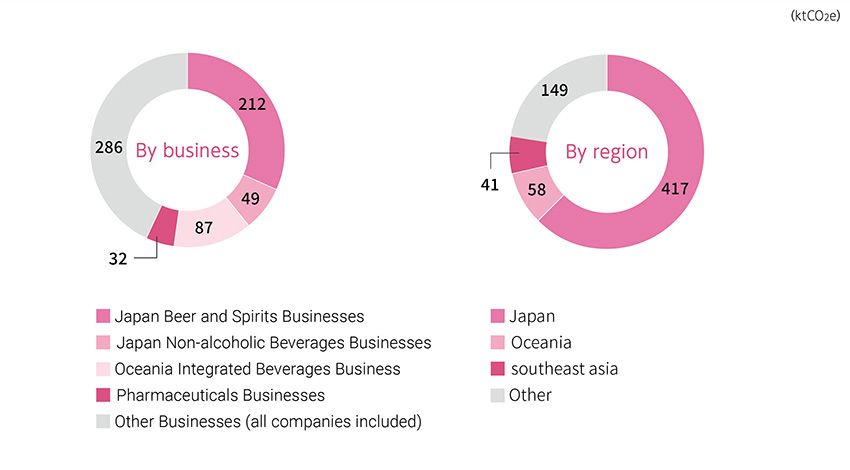

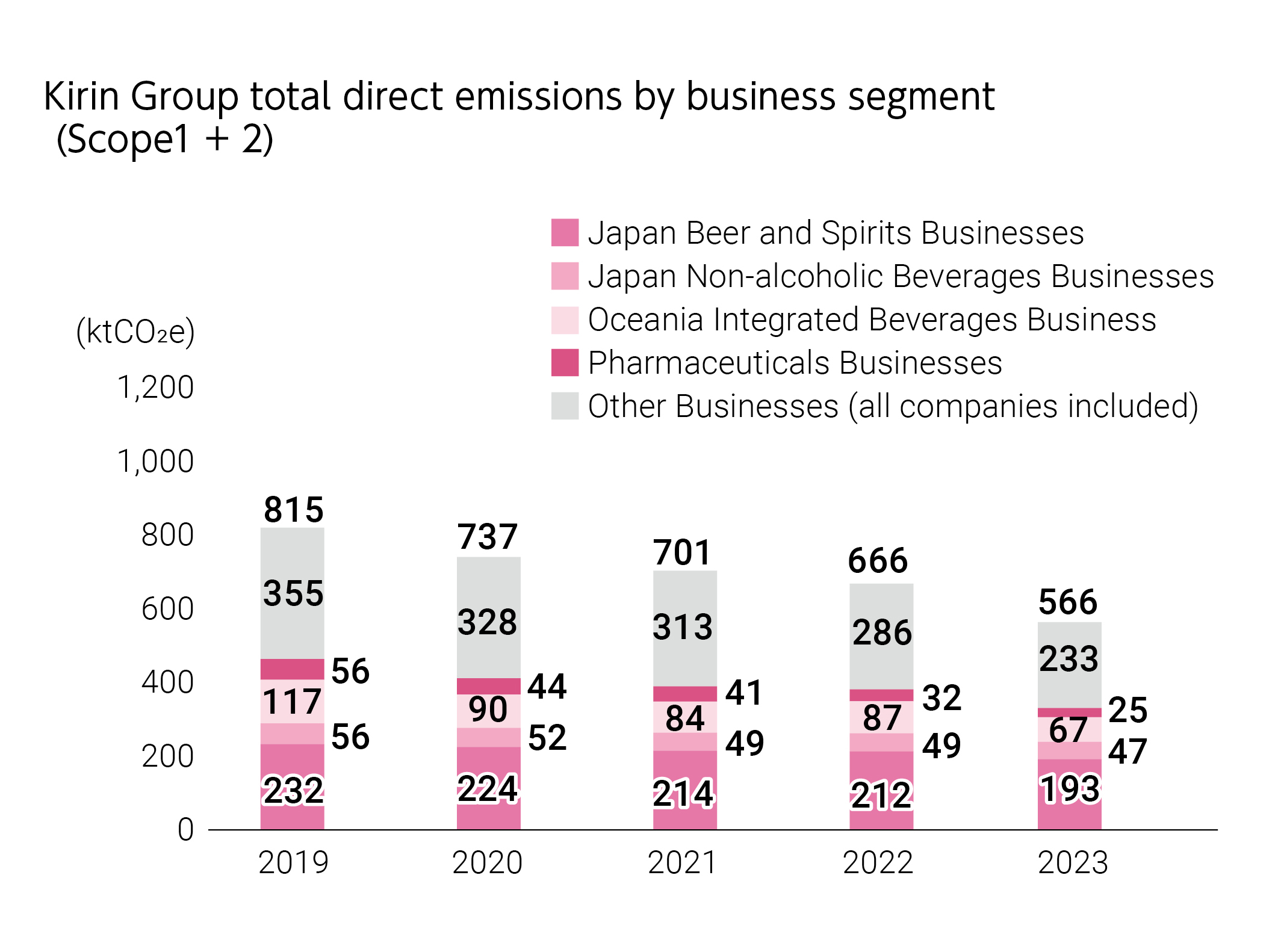

Total emissions for Scope 1 and Scope 2

- Kirin Holdings’ new mid-term GHG reduction target was approved by the Science Based Targets initiative based on 1.5℃ criteria

- Kirin Group joined RE100 Renewable Electricity Initiative Companywide use of 100% renewable electricity by 2040

- Kirin Holdings’ long-term GHG reduction target was approved by the Science Based Targets*1 initiative based on science-based net-zero targets

- Kirin Holdings Selected As “CDP Supplier Engagement Leader” Also Receives The Highest “A-List” Rating In The “CDP Climate Change and Water Security” For 2022

Raw materials

Measures for adapting to climate change at tea farms

The Kirin Group contributes to measures for adapting to climate change through training programs for Rainforest Alliance Certification at Sri Lankan tea farms. Specifically, we instruct people to plant grasses whose roots sink deep into the soil and that crawl the ground on slopes, and thus prevent the runoff of soil from erosion by torrential rain and falls in tea leaf production volumes.

Importing wine in large bags

Mercian ships some of the wine it imports via ocean transportation in specially designed, large 24kl bags (equivalent to about 32,000 of 750ml bottles) with low oxygen permeability, and bottles the wine in plants in Japan. Compared to importing bottled wine, this method lets Mercian reduce GHG emissions during ocean transport by roughly 60% because it eliminates the need to transport heavy bottles by sea, although it increases the amount of GHG emissions from the company’s plants owing to bottling in Japan. We are able to use Ecology Bottles (made with at least 90% recycled glass), lightweight bottles, and PET bottles as containers, which contributes to making effective use of resources and reducing GHG emissions significantly across the entire value chain.

-

Specially designed large bags

In-line blow aseptic filling machine

In the past, we purchased empty PET bottles from container manufacturers and shipped them to plants where we filled them with beverages, to make final products. With an in-line blow aseptic filling machine, we mold PET bottle containers from a material called preform in the production process of the plant and fill them under aseptic conditions. Installation consequently contributes greatly to reducing GHG emissions as using preforms allows us to process greater loads on trucks compared to transporting empty PET bottles. In 2003, we installed preform molding equipment on the beverage production line at Kirin Distillery ahead of other players in the industry in Japan, thereby saving the transportation of preforms. At the Kirin Beverage Shonan Plant, in 2021, we switched our high-pressure compressors for PET bottle molding from V-type reciprocating compressors to inverter-controlled pneumatic machinery in the form of screw compressors and horizontally opposed reciprocating compressors, thereby reducing annual power usage by around 8%. This machinery can recover and reuse waste heat from compressors.

Renewable energy

100% renewable energy for all electric power purchased at plants

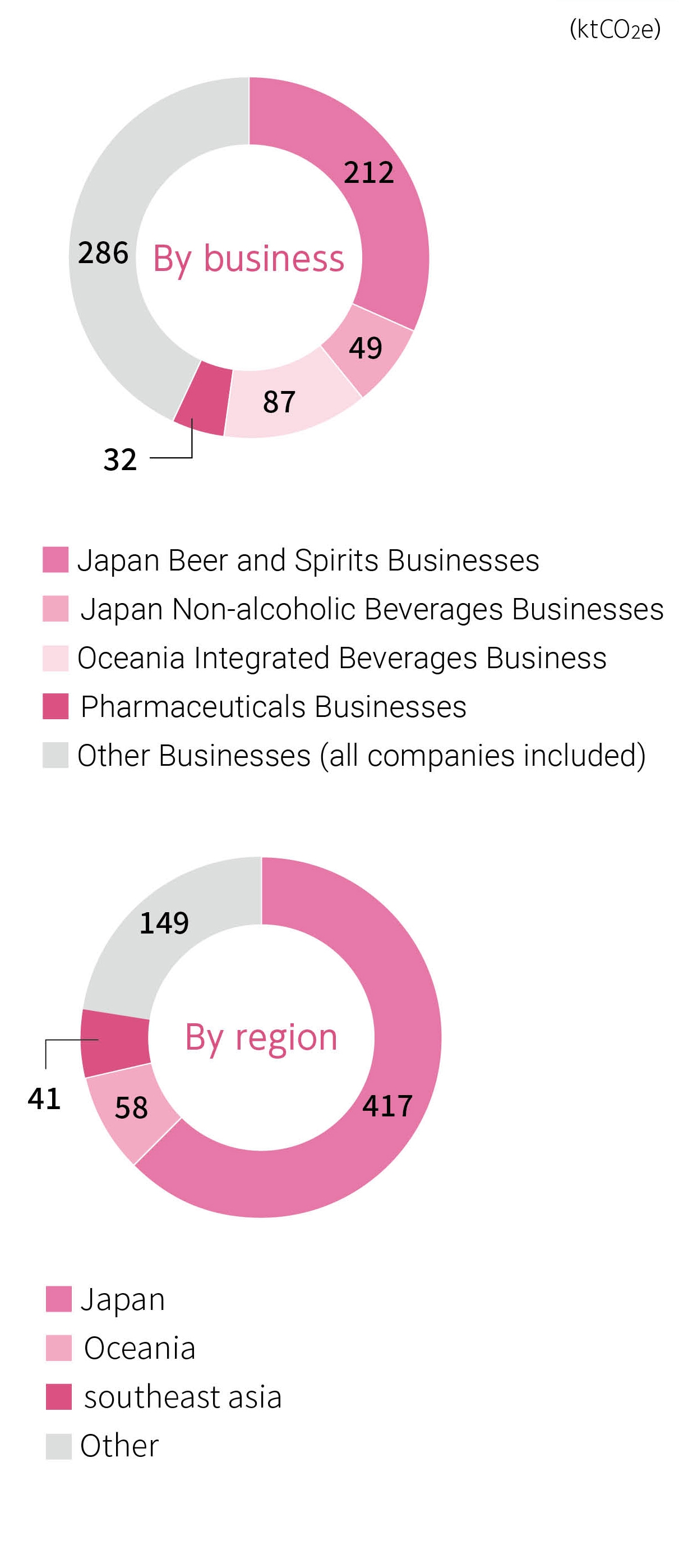

Kirin Brewery has achieved a proportion of 100% of electric power purchased from renewable energy at all Breweries (the Sendai and Nagoya Breweries since 2022, the Fukuoka and Okayama Breweries since January 2023, the Toride Brewery since April 2023, the Chitose, Yokohama, Shiga, Kobe Breweries since January 2024) and all business offices. The company has achieved 100% renewable energy for purchased electric power at nine plants, and the proportion of renewable energy in all electric power used by Kirin Brewery is 66%. In the future, we aim to replace all electric power used across the businesses of the Kirin Group with renewable energy, and soon achieve our RE100 target. Kyowa Kirin has achieved a proportion of 100% renewable energy for all electric power purchased at the Takasaki Plant, Bio Production Technology Laboratories, Fuji Research Park, and CMC Research Center since 2020, and the Ube Plant since April 2023. Through these initiatives, we expect to reduce CO2 emissions across the Kyowa Kirin Group as a whole by 53% by the end of 2023FY, compared with 2019. Since January 2022, all “Château Mercian” wineries producing Japan Wine (Château Mercian Katsunuma Winery, Château Mercian Mariko Winery, and Château Mercian Kikyogahara Winery) have achieved 100% renewable energy by combining green power certificates with purchased electricity.

At breweries in Australia and New Zealand for Lion, 100% of purchased electric power has been sourced from renewable energy since January 2023.

- Kyowa Kirin Has Introduced RE100 Renewable Electricity to All Purchased Electricity at Its Two Plants and Three Laboratories

- Kirin Brewery Completes Installation of Large-scale Solar Power Generators At All Domestic Breweries

- Sunshine State’s XXXX Brewery Now 100 Per Cent Solar Powered

Use of large-scale solar power generation

At the Kirin Group, we are prioritizing “additionality,” which refers to creating new sources of renewable energy in the world. Kirin Brewery has introduced large-scale solar power generation facilities at all nine breweries (eight breweries, excluding the Yokohama Brewery, use the PPA model*1).

At the Mercian Fujisawa Plant, we installed electric power generated from solar power based on the PPA model from March 2023. Through this initiative, we will reduce annual GHG emissions by approximately 124 tonnes, and increase the proportion of renewable energy in electric power used by Mercian as a whole from approximately 5% at present to approximately 8%.

At Kyowa Kirin, we have introduced large-scale solar power generation facilities (1.47MW) based on the PPA model at the Ube Plant (Ube City in Yamaguchi Prefecture), which began operating in March 2023. As a result of the above, we expect to be able to reduce annual CO2 emissions by approximately 1,029 tonnes.

KIRIN GROUP LOGISTICS, Kyowa Hakko Bio, and Shinshu Beverage have leased parts of their premises and building roofs to companies that build large-scale solar power generation facilities, contributing both to effective use of company assets and to the dissemination of natural energy.

- PPA stands for the “Power Purchase Agreement” model and refers to an agreement between a business that sells electricity to users (PPA provider) and the users of electric power. At Kirin Brewery, MCKB Energy Service Co., Ltd., a subsidiary of Mitsubishi Corporation Energy Solutions Ltd., acts as a PPA provider, installing megawatt-class solar power generation facilities on the roofs of breweries, while Kirin Brewery purchases and uses the power generated.

Use of solar power generation in Australia

At Lion in Australia, we installed solar power generation facilities at Castlemaine Perkins Brewery in 2019 and at Little Creatures Geelong Brewery in Victoria in 2020.

The largest brewery in New South Wales, Tooheys Brewery, has signed a PPA agreement with a renewable energy distributor in partnership with the Australian Hotels Association (AHA), which consumes a low amount of energy. By jointly signing a large power contract, the AHA was able to introduce renewable energy at a lower cost, successfully reducing the cost of power for pubs from 11.5c/kWh to 6.9c/kWh.

In order to obtain Climate Active*2 certification in Australia, Lion must disclose carbon credits used to offset total emissions for the year in its annual report, and Lion has been complying with this requirement. This certification standard is a new standard for carbon neutral certification in Australia.

In New Zealand, Lion obtained Toitū*3 carbon zero certification in 2021.

- A third-party certification body established by the government of Australia

- A third-party certification body established by the government of New Zealand

Renewable energy certificates

Since 2021, Kyowa Hakko Bio has introduced “Renewable Energy Certificates (I-REC)” at Thai Kyowa Biotechnologies in Thailand. This marks the first adoption of these certificates in the pharmaceutical and food industries in Thailand, and we expect it will enable us to reduce annual GHG emissions by 10,200 tonnes, thanks to the use of renewable energy sources for some of the electricity used in the plant.

Wind power

Through a consortium represented by Mitsubishi Corporation Energy Solutions, Ltd., Venti Japan Inc., C-Tech Corporation, and Mitsubishi Corporation have been selected as power generation business operators for projects off the coast of Noshiro City, Mitane Town, and Oga City in Akita Prefecture, off the coast of Yurihonjo City in Akita Prefecture, and off the coast of Choshi City in Chiba Prefecture, through a consortium (the “Consortium”) represented by Mitsubishi Corporation Energy Solutions, Ltd. Kirin Holdings is a partner of the Consortium. These projects are Japan's first fixed-bottom offshore wind power generation projects in general sea areas. They will be among the largest sources of power in Japan, and will make a significant contribution to the Japanese government's commitment to achieve carbon neutrality by 2050. The maximum power output of the three projects will be approximately 1.69 million kW, which is sufficient to meet the electric power demand of approximately 1.21 million households.

Production

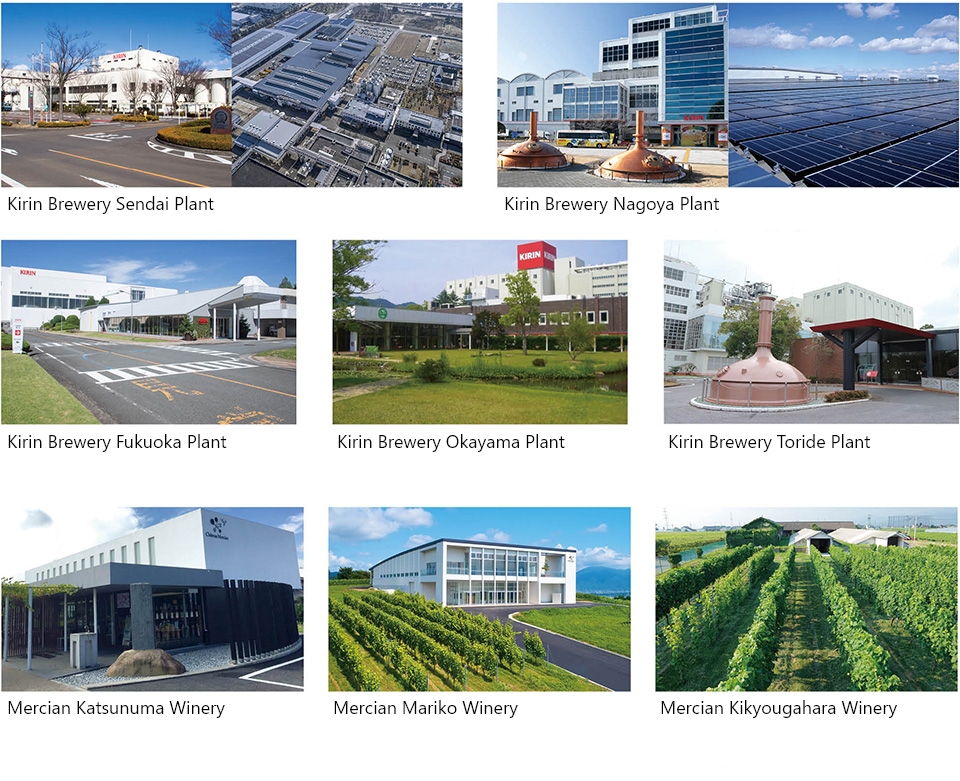

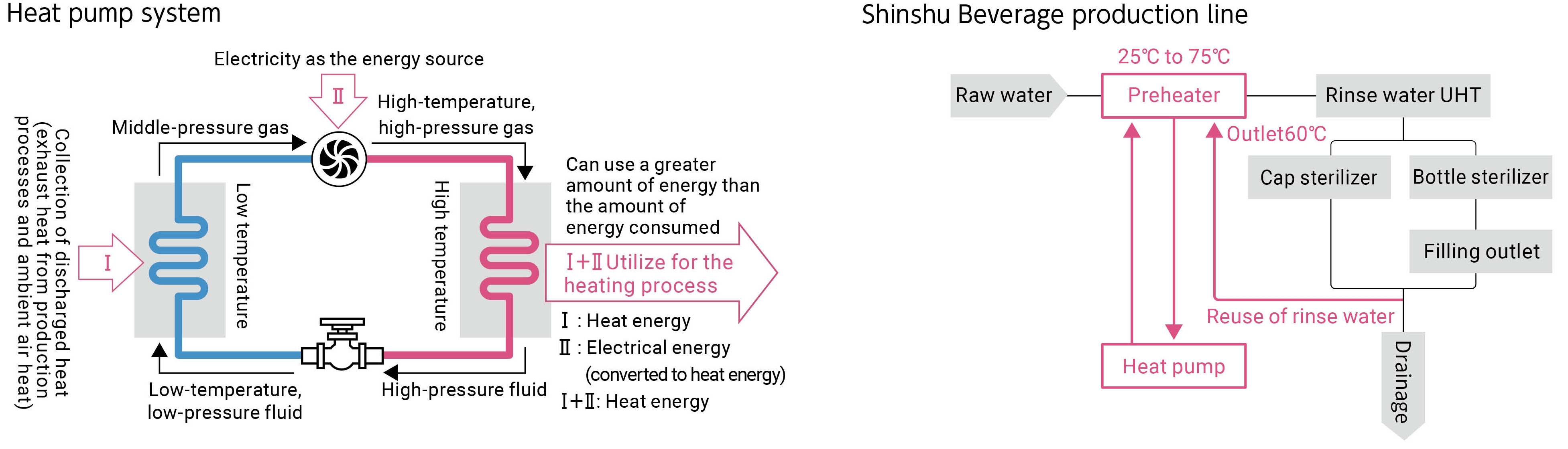

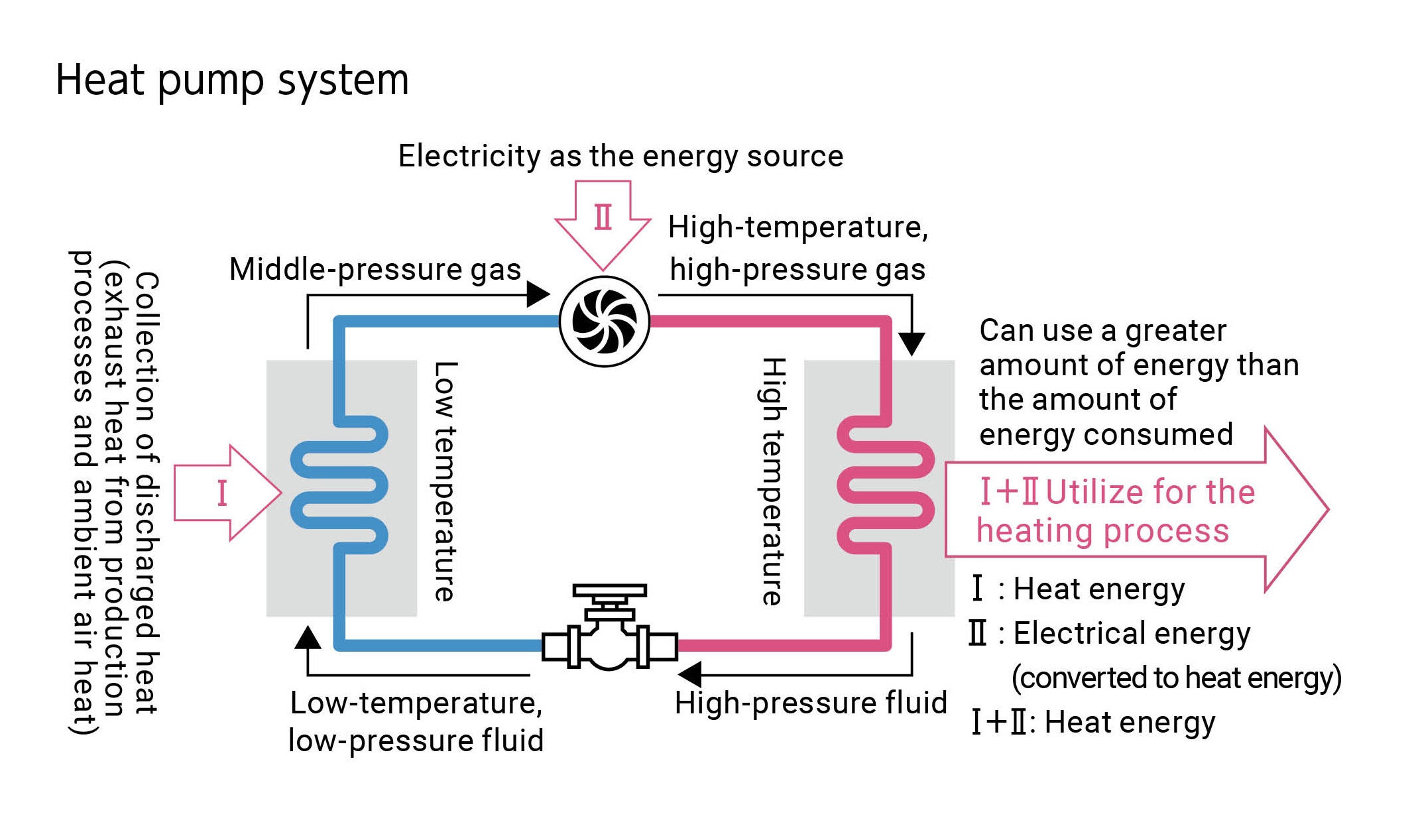

Use of heat pumps in production processes

The Kirin Group must improve energy efficiency and reduce the amount of energy consumption. At the same time, we believe that shifting the energy mix from fossil fuels to electric power, and, furthermore, using electricity generated by renewable energy sources are the most effective ways of reducing GHG emissions.

Kirin Brewery has successfully reduced its GHG emissions by approximately 70% over the 25 years from 1990 to 2015. In 2019, we introduced heat pump systems at the wastewater treatment facilities of six Kirin Brewery plants, thereby reducing GHG emissions by 3% (approximately 4,800 tonnes) from the previous year across Kirin Brewery as a whole (as of November 2023).

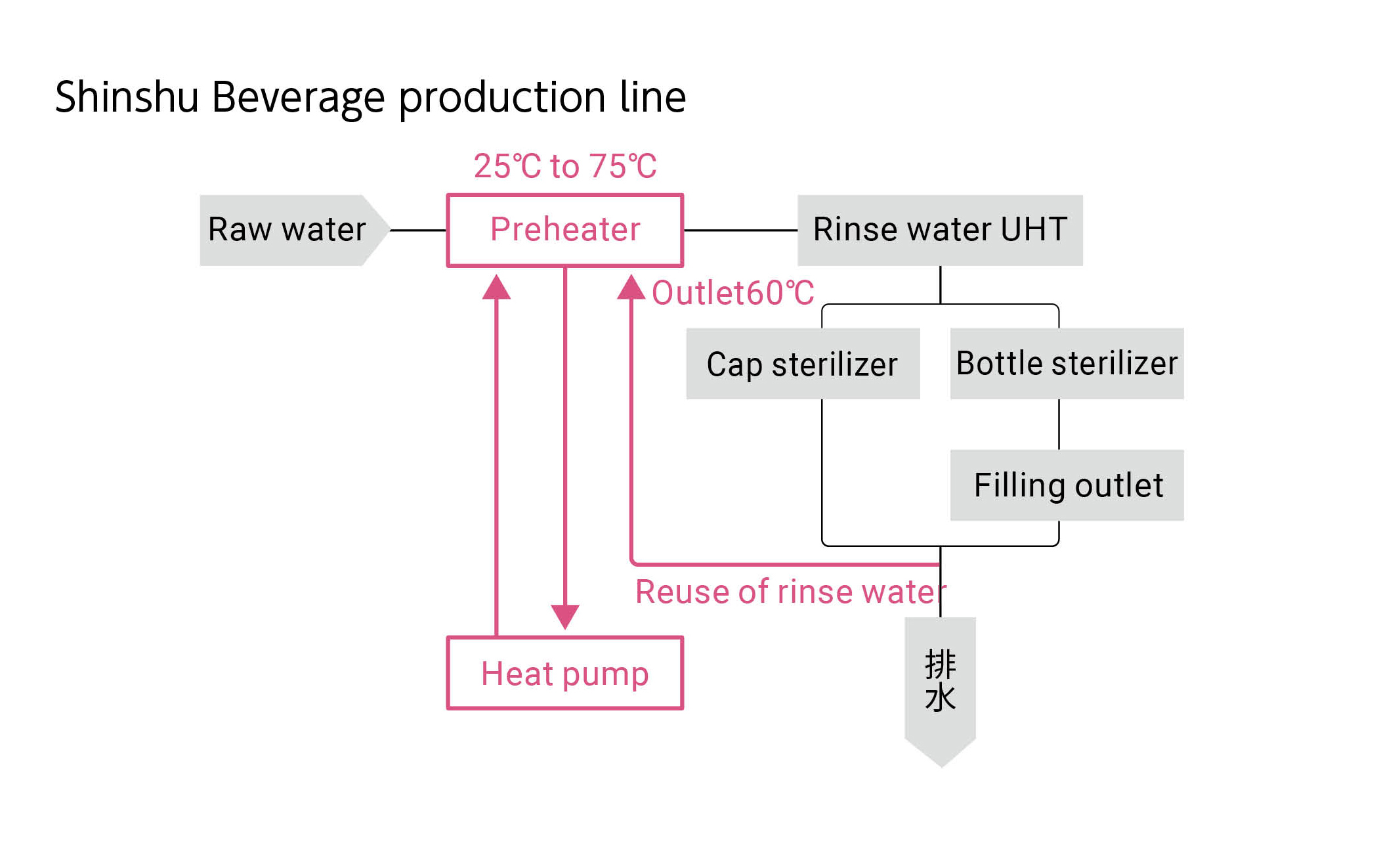

At Shinshu Beverage, we reuse waste heat, which is difficult to use directly in rinsing processes for bottles and caps, through a heat pump unit, enabling us to reduce GHG emissions by approximately 970 tonnes per year. The Kirin Brewery Okayama Plant has reduced annual GHG emissions by approximately 180 tonnes by reusing waste heat in hot water sterilization equipment for cans and heat in the air.

Fuel Shift

The majority of the fuel we use at breweries is consumed in the boilers that generate steam. At all Kirin Brewery and Kirin Beverage plants, we have completed the shift to natural gas, which generates less GHG emissions than heavy oil.

We have achieved more efficient boiler operations through the installation of highly efficient small boilers in line with the fuel shift. We have introduced cogeneration systems to provide some of the plants’ heat and electricity.

-

Cogeneration

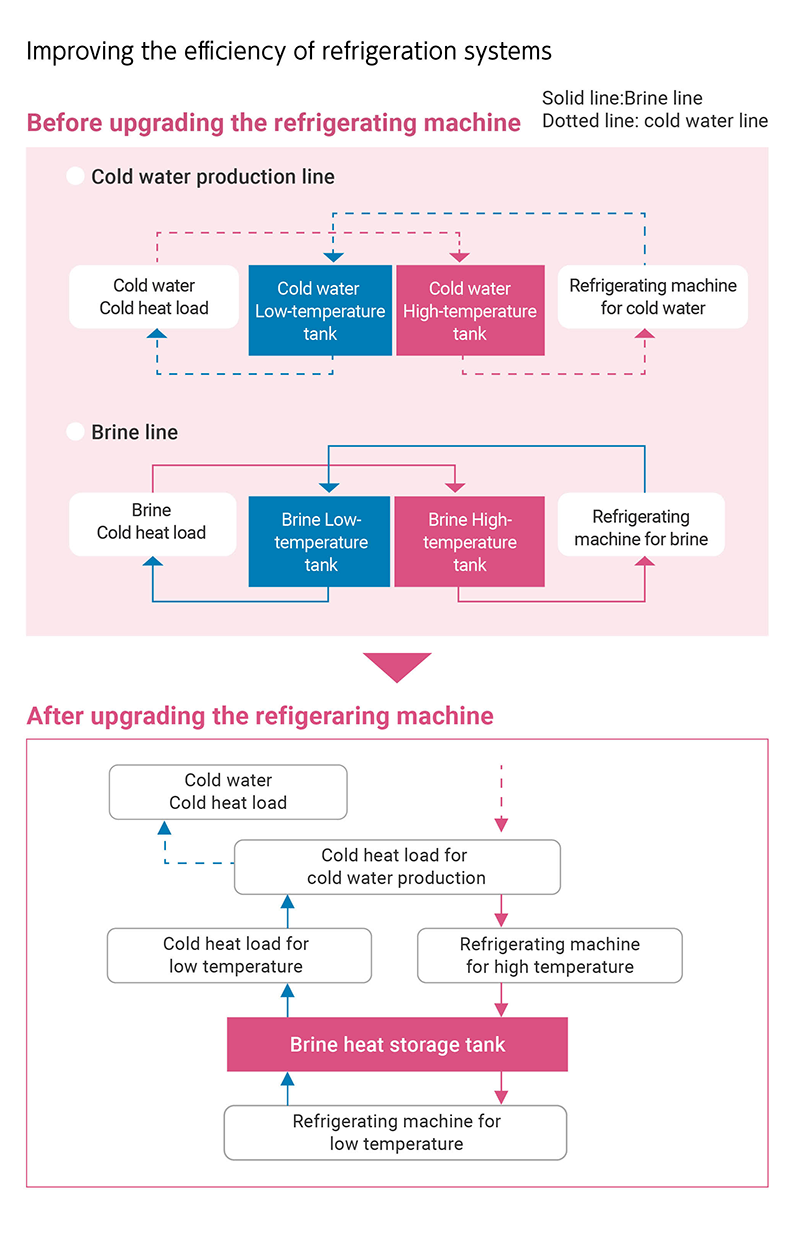

Improving the efficiency of refrigeration systems

At Kirin Brewery, we reduce energy consumption through improving the efficiency of refrigerating systems. We are introducing a cascade refrigeration system, which cools in phases, for processes that involve a considerable temperature difference, and we are also making operational improvements to refrigeration systems.

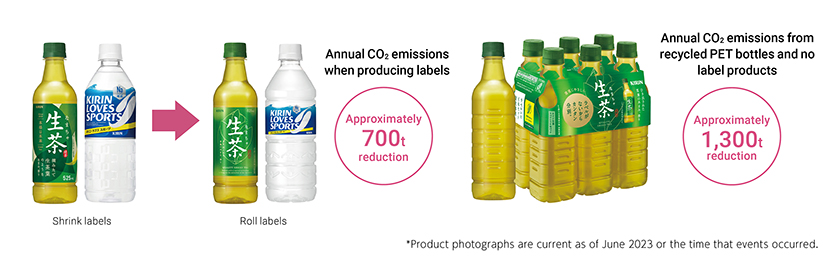

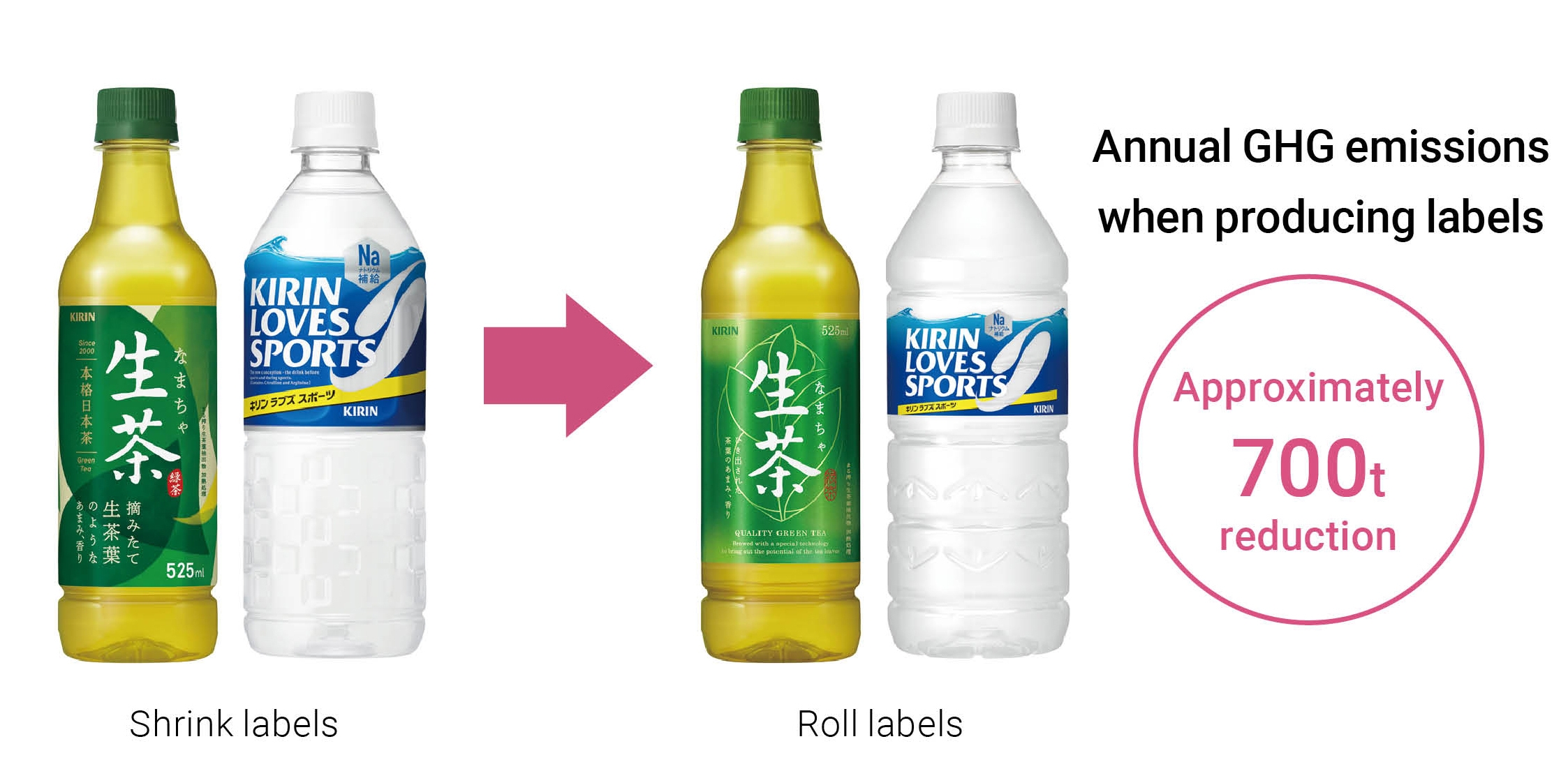

Containers

Reduction of GHG emissions during transportation by reducing container weight

Making containers lighter leads to reducing GHG emissions in the manufacturing process of containers and packaging and improving loading efficiency, which leads to the reduction of GHG emissions. Between 1990 and 2022, Kirin Brewery and Kirin Beverage reduced GHG emissions from container manufacturing by a total of 5.07 million tonnes*1 by reducing the weight of containers and packaging.

- Calculated based on the Carbon Footprint Product Category Rule (Certified CFP-PCR Number: PA-BV-02) applied to the difference in the weight of containers between 1990 and each fiscal year, multiplied by the usage of containers in the relevant fiscal year, from 1990 to 2022

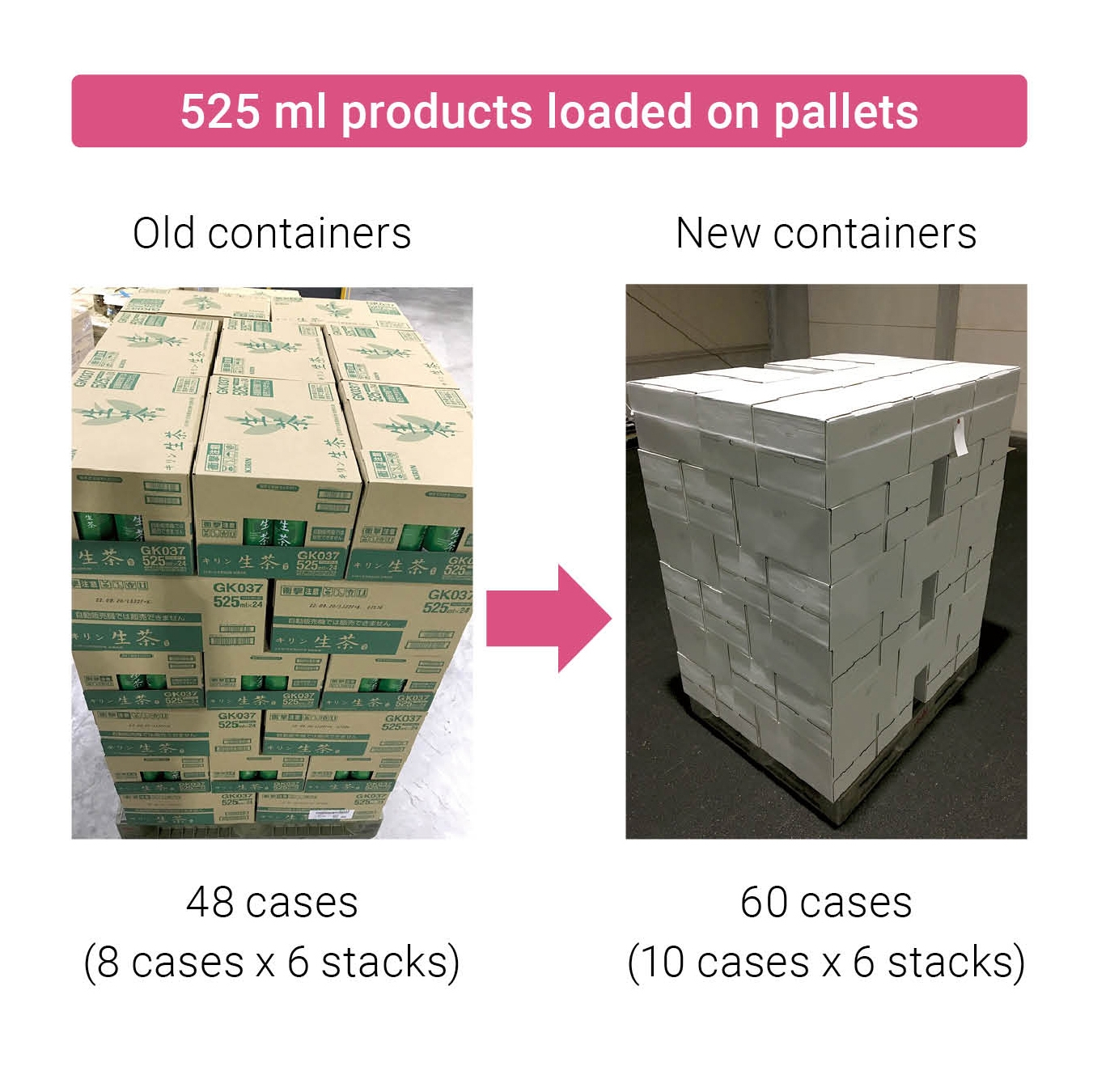

Improving loading efficiency for transportation

Kirin Beverage has adopted a bottle shape that enhances loading efficiency, enabling us to increase the number of bottles per pallet. Since April 2022, we have been using square PET bottles for Kirin Nama-cha and Kirin Nama-cha Hoji Sencha (525 ml and 600 ml), as part of the expansion of our activities to medium-sized PET bottles. By adopting a square shape, we have increased the number of boxes loaded per pallet for 525 ml bottles from 48 cases (8 cases x 6 stacks) to 60 cases (10 cases x 6 stacks), improving loading efficiency by a factor of 1.25, and for 600 ml bottles, from 48 cases (8 cases x 6 stacks) to 50 cases (10 cases x 5 stacks), improving loading efficiency by a factor of 1.04.

- Product photographs are current as of June 2023 or the time that events occurred

Logistics

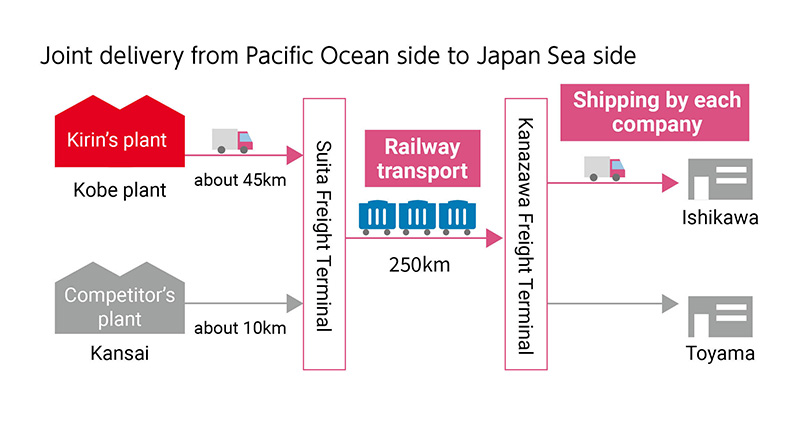

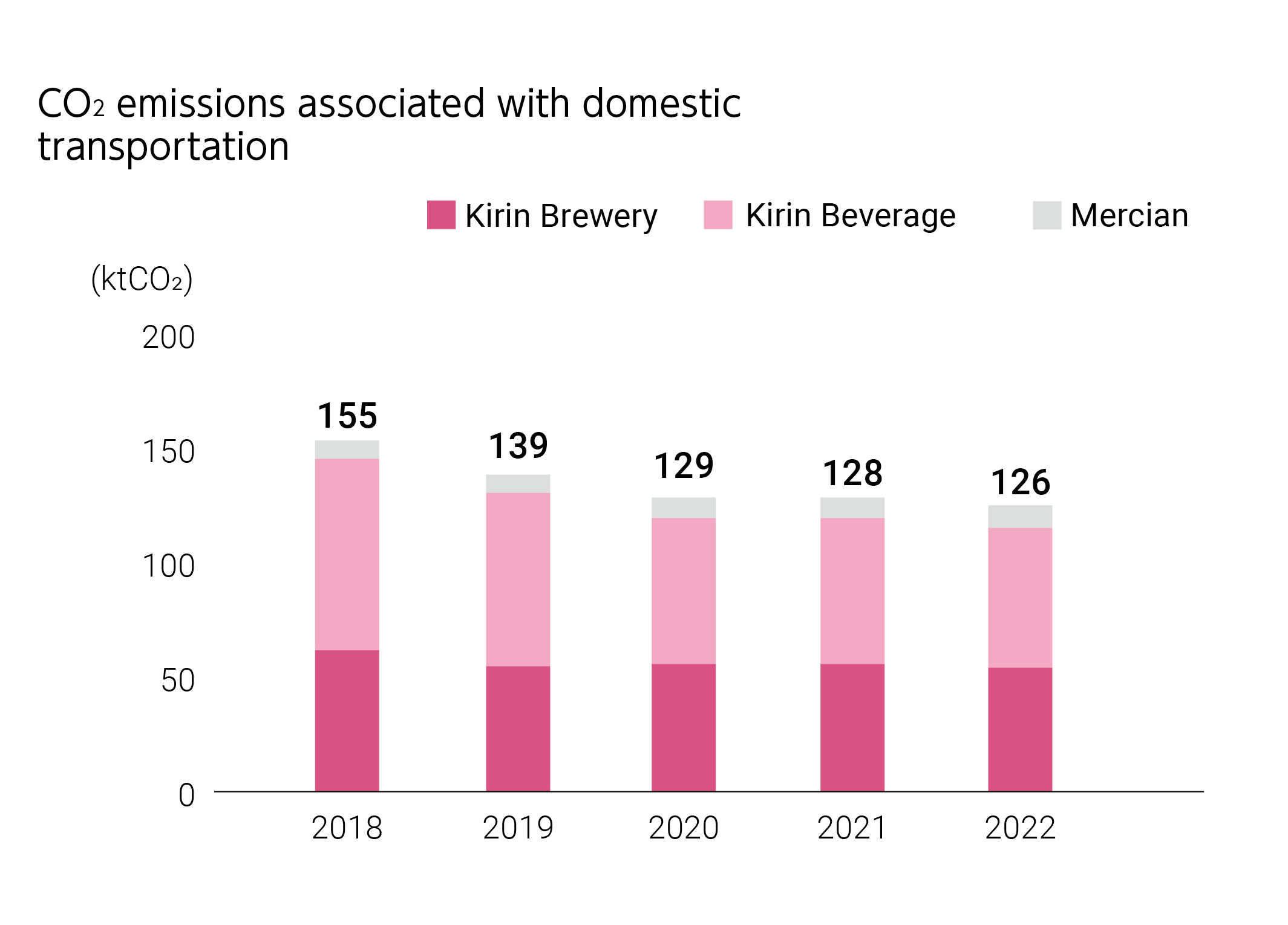

We are promoting joint deliveries and a modal shift

The Kirin Group has positioned the logistics area as a non-competitive sector and is actively engaging in initiatives together with other companies.

In 2017, together with other companies in the industry, we established a joint delivery center in Kanazawa City, Ishikawa Prefecture, and launched joint transport by rail container from plants in the Kansai area. Neither of the companies has plants on the Japan Sea side, so products previously had to be transported by truck over long distances—of 200 km—from their plants on the Pacific Ocean side. This was inefficient and placed a great burden on the truck drivers. Joint transportation using rail containers has not only significantly reduced GHG emissions but shortened distances between the plants and the terminals and between the terminals and the destinations with a significant alleviation of the burden on drivers, which is helping to solve the social issue of a shortage in truck drivers. Through these efforts, we have successfully completed a modal shift from long distance truck transportation, equivalent to 10,000 vehicles a year, to railway containers, and we estimate that we can thus annually reduce GHG emissions by approximately 2,700 tonnes.

In September 2017, we began joint delivery in the eastern Hokkaido area. As a result of these efforts, we are effectively utilizing railway containers and have enhanced truck loading efficiency, leading to more efficient logistics. We estimate that this results in a reduction in annual GHG emissions of approximately 330 tonnes.*1

The Kirin Group is actively pursuing a modal shift of switching from truck transport to rail and ocean transport, which has lower GHG emissions, for long-distance shipments (400 to 500 km or more).

- Contribution to Avoided Emissions through the Global Value Chain, Fifth Edition, Keidanren (Japan Business Foundation)

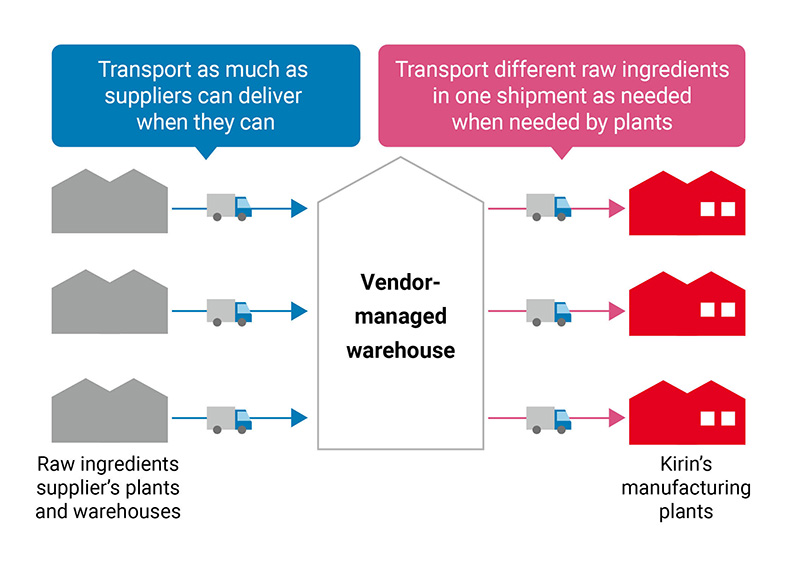

Vendor-managed warehouse

With the aim of mitigating the risk of not being able to transport due to an unavailability of trucks and optimizing transportation efficiency, we started a trial operation of a raw materials procurement and distribution system using a raw materials warehouse (vendor-managed warehouse) adjacent to Kirin Beverage’s in-house plants, the Shonan Plant and Shiga Plant, from October 2019. By establishing this facility as a vendor-managed warehouse, raw material and ingredient suppliers can transport the desired amount of raw ingredients when they need to, thereby maximizing efficiency. This has made it easier to cope with sudden changes in production plans, and contributed greatly to improving the responsiveness of plants.

Sale

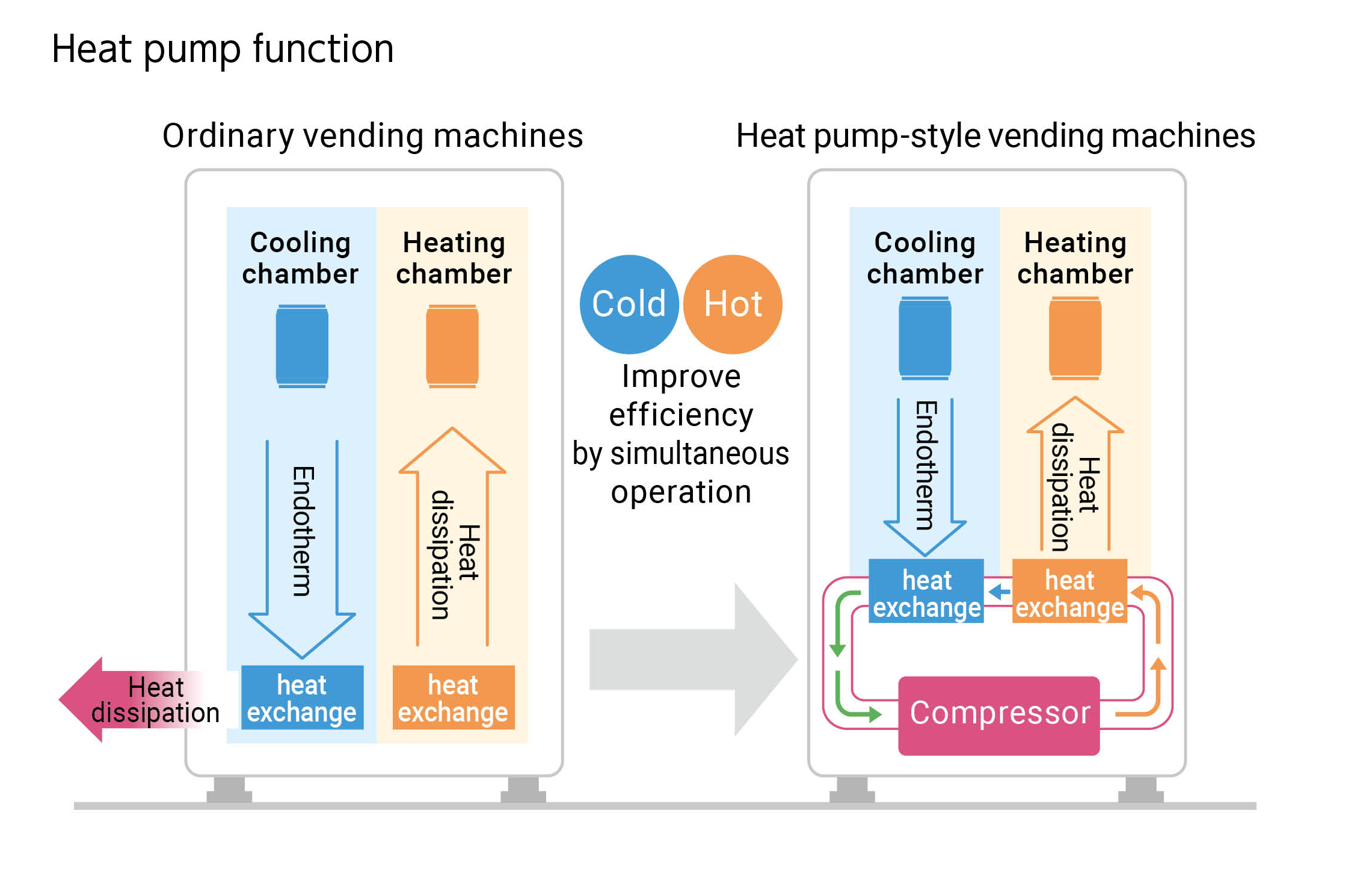

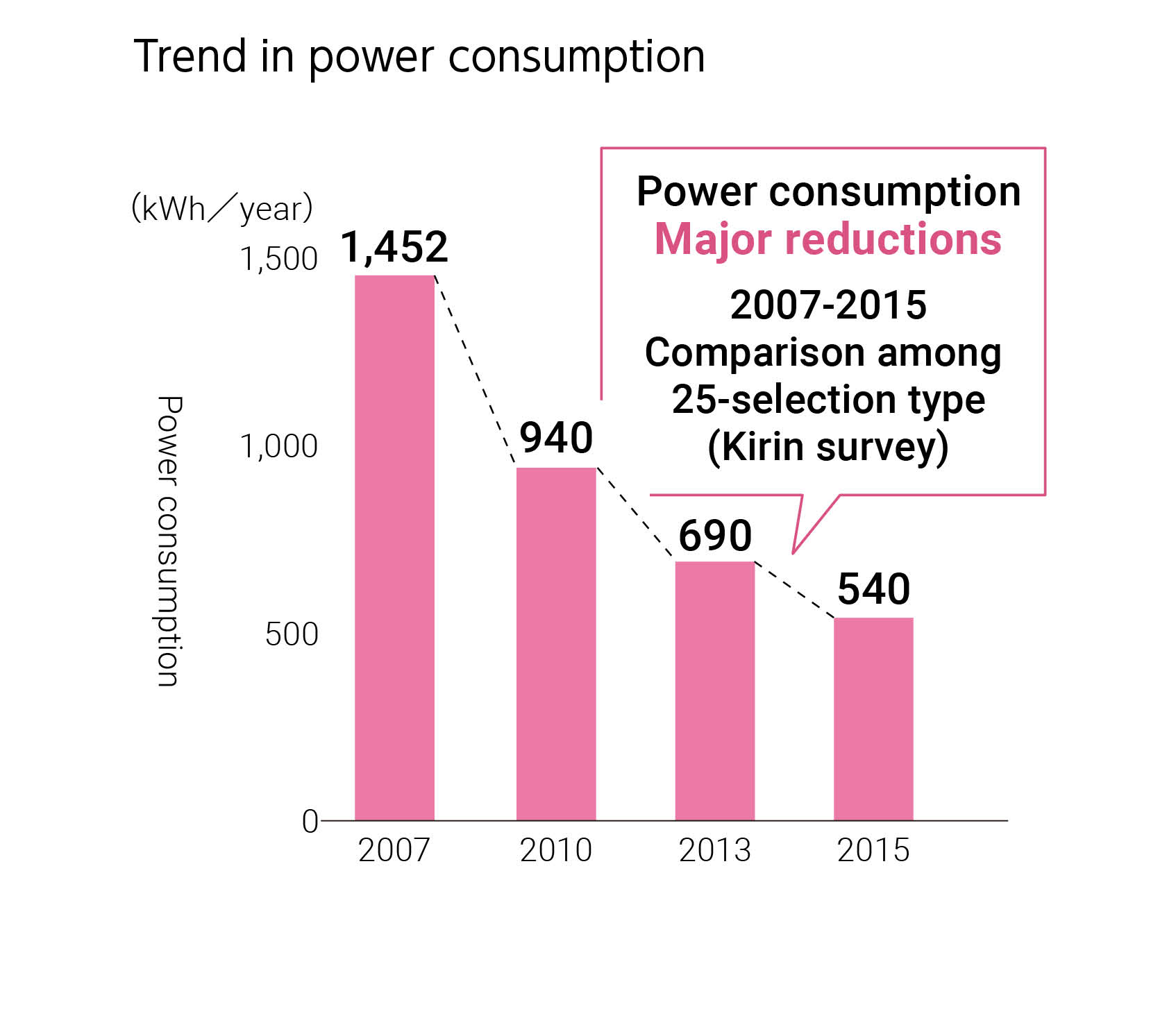

Becoming an industry pioneer in introducing “heat pump-style vending machines”

Kirin Beverage was the first in the industry to introduce heat pump style vending machines in 2006, and from 2012, almost all newly installed vending machines for cans and PET bottles are of this type. As of April 2023, we have switched more than 90% of installed vending machines to this type.

Heat pump-style vending machines pump up the waste heat generated when cooling products and use it for heating to warm up the products. This allows reduction in power consumption compared to conventional vending machines by cutting down the power used by the heaters.

Some types offer higher energy-saving performance, such as with heating functions not only by using the waste heat released by the cooling chamber as previous models did, but by capturing the heat from outside the machine, and by improving hot and cold insulation performance with the heavy use of vacuum insulation materials.

These vending machines have evolved to the point where power consumption can be reduced by about 40% compared to 2013. Installation of the new models began in 2015, and we are aiming for 80% of the new machines we install in 2023 to be new models.

Carbon zero certified beer

Steinlager, which Lion sells in New Zealand, has obtained certification as a carbon zero beer under the Toitu program by a body of the New Zealand government. In 2021, we featured the Toitu carbon zero mark in our marketing campaigns to highlight to consumers the commitment Lion has made to reducing GHG emissions through Steinlager and other products.

In May 2022, Lion began selling “XXXX Zero,” Australia’s first carbonneutral and alcohol-free beer. XXXX Zero has obtained carbon neutral certification in the form of Climate Active certification.

In Australia, Lion is preparing to acquire carbon neutral certification through Climate Active for many key products. In order to obtain certification, Lion is working to comply with the requirement that it must offset all GHG emissions from the complete life cycle of the product, including emissions from raw materials and packaging, distribution and product waste.

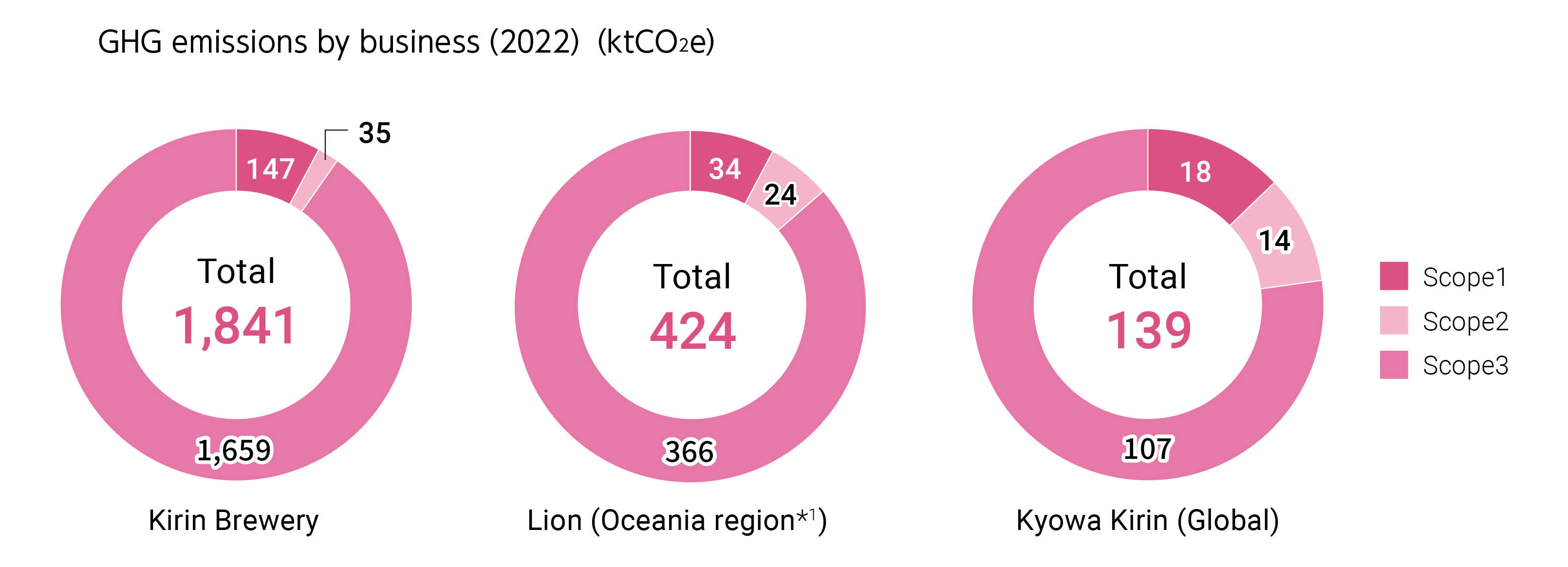

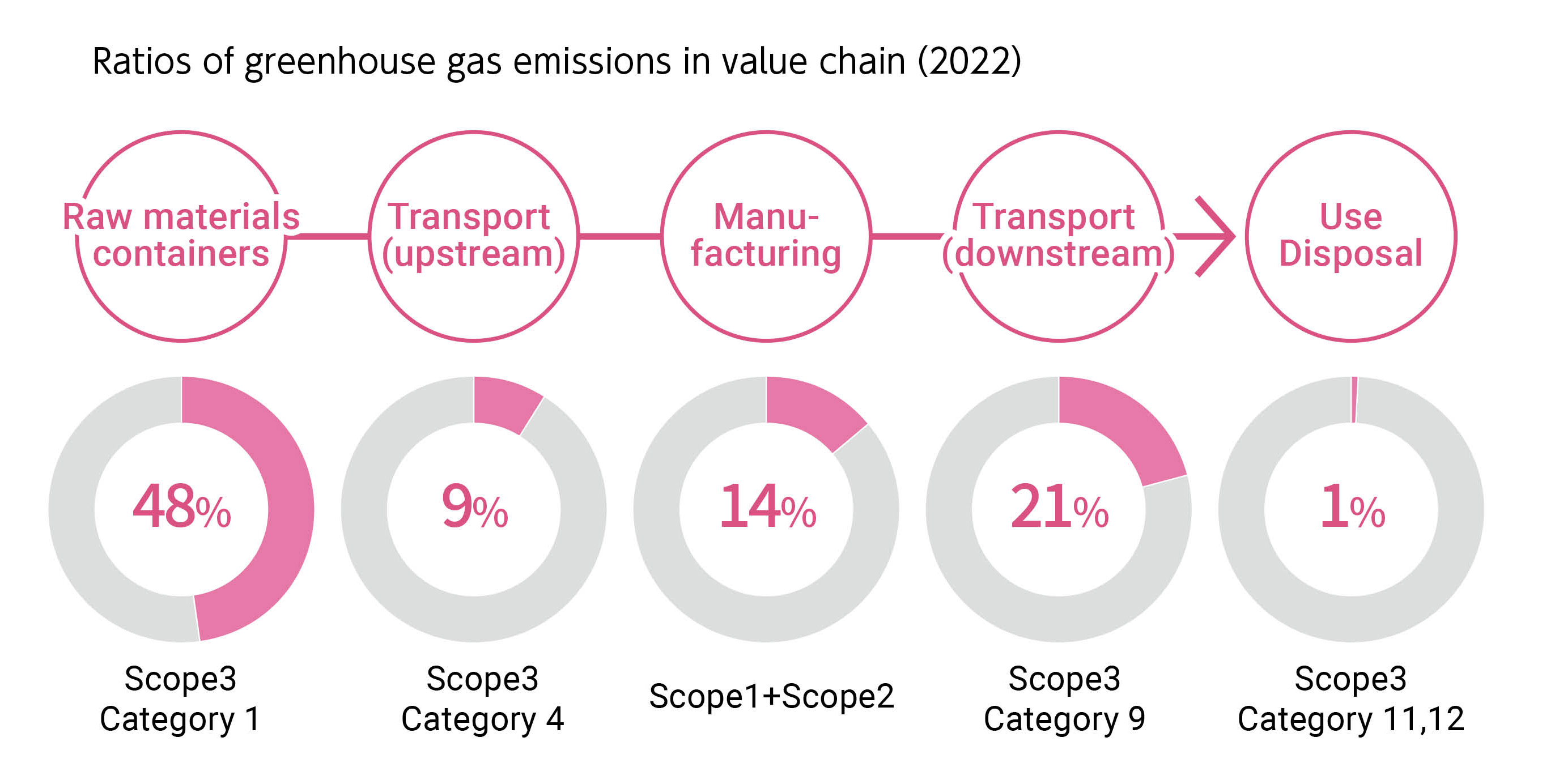

Key data related to climate change

Since 2019, we have excluded Lion’s non-alcoholic beverages business from Scope 3 emissions, and we have changed to the LCA database(IDEA) offered by the National Institute of Advanced Industrial Science and Technology (AIST) for emissions per unit of production.